cnc machining guidelines Design Guidelines Part Complexity CNC machining can efectively produce highly complex designs; however, that does not mean you should not strive to simplify your designs. A part with contoured geometry or multiple faces that need to be cut will typically take Here are some guidelines for selecting the appropriate junction box for wall sconces: The junction box should comply with local electrical codes and regulations. These codes typically specify .

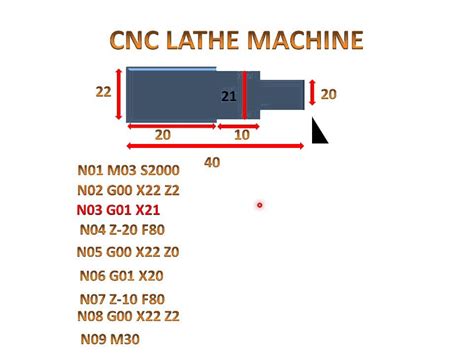

0 · cnc turning programming pdf

1 · cnc turning drawing pdf

2 · cnc pdf free download

3 · cnc machining manual pdf

4 · cnc machining handbook pdf

5 · cnc machining basics pdf

6 · cnc machine operator training pdf

7 · cnc machine maintenance manual pdf

The fan I'm trying to install needs at least 35 lbs weight (actual weight of fan is around 15 lbs). Do I use 10-32 screws or 10-24, and what length? Can you figure out the brand name on the box? In metal boxes it’s often stamped into the metal on the inside, sometimes you can see it through paint, but that paint does look thick.

Make the most of CNC machining by optimizing your design and making the right material choices. Read these 14 design tips to help you reduce CNC-machining costs and create the perfect parts for your project.Get quick advice on creating plastic, metal, elastomeric, and LSR parts for 3D printing, CNC machining, sheet metal fabrication, and injection molding.Design Guidelines Part Complexity CNC machining can efectively produce highly complex designs; however, that does not mean you should not strive to simplify your designs. A part with contoured geometry or multiple faces that need to be cut will typically takeFor CNC routed materials, we use a chip-subtractive method (2-dimensional CNC flatbed machining) to cut your parts. We’ll use a 0.125″ bit, so allow for a radius of .063” on all internal geometry and minimum hole size of .125”.

Best Practices and Partnering with CNC Machining Services. Following these guidelines can significantly improve the quality of threaded holes, leading to better performance in assembled parts. Our CNC machining services near you can provide valuable expertise and state-of-the-art equipment to achieve precise threading. However, while CNC machining is versatile and productive, knowledge of the design process and machine operations is still important if you are to manufacture high-quality products. This is why in this design guide for CNC machining, we will discuss everything you need to know about CNC machining design and guidelines. So, read on.

Another safety issue of CNC machining is the possibility of electrical hazards, such as shocks, fires, and explosions. These hazards can result from faulty wiring, damaged insulation, improper . These CNC Machining design guidelines advise engineers and designers on how to design cost-efficient parts that can be successfully CNC machined with the least effort. {{cta-banner}} CNC design considerations. The design of a CNC part should consider various elements during the initial design phase, such as: Key Guidelines for Plastic CNC Machining. June 16, 2021 by SyBridge Technologies. Originally published on fastradius.com on June 16, 2021. Plastic CNC machining is a subtractive manufacturing process in which a solid block of plastic is placed against a moving cutting tool that removes material from the block. The cutting tool follows a set .Design Guidelines - Part Complexity - Fillets - Holes - Pockets and Cavities - Wall Thickness - Threads & Tapped Holes - Embossed & Engraved Text - Undercuts; . Our partners support the latest in CNC machining and turning processes, can support a high level of part complexity, and provide exceptional surface finishes. We can also machine and .

Operating a CNC (Computer Numerical Control) machine requires adherence to a well-defined set of procedures to ensure safety, efficiency, and accuracy. This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and maintenance.

cnc turning programming pdf

CNC Machining Design Guidelines 1. Inner Edges. Computer numerical control machines usually operate with circular drill bits making it difficult to make sharp internal edges. The circular shape of the drill bit leaves a space behind where an inner edge was supposed to be created. With less space where the drilling machine couldn’t reach is . The CNC machining process offers several benefits due to its automation and use of machine tools controlled by computers to create parts from raw materials. These benefits include increased precision, consistency, speed, and the capacity to create precise features with complex geometries. In addition, it also works well to create parts from plastic, metal, and .CNC Machining Guidelines. Part should be scaled correctly, 1:1; Files should only contain your parts/cut-paths; Shapes, holes or cutouts are at least 50% material thickness; Part is in .STP or .DXF format only; Part is no taller than 2″ Part is no larger than 8″x8″ No geometry (hole or cutout) is below .125″ wide (the size of our . Internal edges, particularly the vertical corner radius, are crucial in CNC machining. The recommended value for this is at least one-third of the cavity depth. Adhering to this guideline ensures that the right diameter tool is used, which aligns perfectly with the cavity depth guidelines. But there's more to it than just following guidelines.

Online CNC machining service for prototypes & production parts. Instant quotes for 1-1,000 units and tolerances to ±0.0008 inches. 20% off your first order. Save up to ,000/€1,000. Ends 30 Nov 2024. . in-depth design guidelines and explanations of different surface finishes.

7. Which CNC machining plastics typically require annealing? We have discussed the situations that need plastic anneal. Some plastics for CNC machining may need to anneal more frequently than others. 7.1 Annealing .

Guidelines | Improve your knowledge of materials and technologies here: articles help you design better parts and increase your professionalism . The Weerg Blog collects up-to-date articles on 3D Printing and CNC Machining. SUBSCIBE TO OUR NEWSLETTER . Guidelines. 2 min read. Sandblasting. Weerg staff: Oct 24, 2024. 3D Printing Guidelines MJF .

cnc turning drawing pdf

cnc pdf free download

cnc machining manual pdf

While preparing the CNC machining design, there are a few things to keep in mind to optimize your strategy and remove any uncertainty for us, allowing us to provide the parts exactly as you desire. You will find guidelines for material .In the realm of modern manufacturing, CNC machining stands out as a versatile and precise method for creating complex parts with exceptional accuracy. However, achieving the best results from CNC machining involves more than just programming the right toolpaths. The foundation for success lies in designing parts that are inherently well-suited for the machining process.

CNC Machining. CNC Machining. CNC Milling. CNC Turning. Wire EDM Machining. Medical CNC. CNC Routing. Sheet and Tube Fabrication. Sheet Metal Fabrication. Sheet Cutting. Laser Cutting. Waterjet Cutting. Laser Tube Cutting. Tube Bending. Plastic Part Production. Plastic Injection Molding. Quick-Turn Molding. Prototype Molding.

CNC Machine Safety Guidelines Many new CNC machines offer state-of-the-art safety features, but unfortunate accidents occur when operators deviate from the equipment manufacturer’s guidelines. These incidents can happen when workers become distracted, try to speed up a process, or inappropriately modify a tool.

Our CNC machining service provides the ability to easily add threaded features to milled and turned parts. See which threading options are available. . Guidelines on how to supply custom resin for your next project. New 3D Printing Materials! Tough Black (Loctite Henkel 3843) and Ceramic-Filled (BASF 3280) are two new advanced photopolymer . ISO 9001: 2015 is a standard that provides guidelines for organizations to carry out production. Read on how CNC shops implement ISO 9001. . Moreover, ISO 9001: 2015 enables CNC machine shops to carry out every workshop activity in an organized fashion, identify potential causes of defects in products, reduce cost, increase profits, and . It is, therefore, crucial to implement CNC machine safety guidelines and best practices to prevent such accidents. For a start, modern machines come with safety features. Nonetheless, they do not guarantee 100% safety. However, the responsibility for safety still lies with the operator or machinist. They must wear PPE, perform regular .

Speed & Feeds for Turning, Drilling & Milling Plastics, Sawing Guidelines, Coolant Recommendations, Trouble Shooting Quick Reference, Annealing, Learn More 1-800-444-3485 Toggle navigation Polytetrafluoroethylene (PTFE) is a fluorocarbon-based polymer that is commonly referred to as Teflon® by DuPont. This thermoplastic is favored for applications involving backup rings, coatings, distribution valves, electrical insulation, and more due to its enhanced electrical properties, high-temperature capabilities, and chemical resistance.Our most recent machining . CNC Machining . PRACTICAL MACHINIST RULES AND GUIDELINES. Thread starter Milacron; Start date Sep 4, 2022; Replies 1 Views 4,264 Status Not open for further replies. . MACHINE DISCUSSION GUIDELINES Note this is the is the Manufacturing Forum, not the home shop machinist forum. And while all levels of "how to" metalworking or woodworking .

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion. . It’s a fair question, but as long as safety guidelines are followed, magnesium can be an excellent material choice for CNC machining. Magnesium is the lightest structural metal, and it also provides an .

big steel box surrey bc

big cnc milling machine

Here we report a nanoreactor-confined crystallization strategy that enables rapid and roll-to-roll fabrication of high-performance ultra-thin (∼ 25 nm) MOF hybrid membranes .

cnc machining guidelines|cnc pdf free download