making rounded parts from sheet metal solidworks Using the SOLIDWORKS Lofted Bend feature, you can create flat patterns to transition a square sheet metal opening down to round sheet metal opening. The process usually requires heating the two pieces of sheet metal up to the melting point, then using a torch to weld them together. The Welding sheet metal process is commonly found on aircraft, cars, trucks, appliances, boats, ships, and other industrial equipment.

0 · solidworks sheet metal shapes

1 · solidworks sheet metal pattern

2 · solidworks sheet metal parts

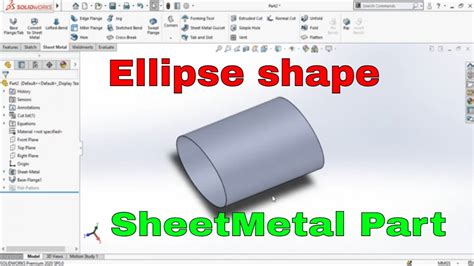

3 · solidworks sheet metal cylinder face

4 · solidworks sheet metal cylinder

5 · solidworks sheet metal

6 · solidworks round bend sheet metal

7 · solidworks rolling sheet metal parts

Sand the weld flat with a metal angle grinder or Dremel tool. Try using an angle grinder fit with an abrasive flap wheel, for instance. Wait at least 30 seconds for the weld to finish cooling, then hold the wheel up to each spot.

To create a sheet metal part with round bends: Sketch a closed or open profile. Create a thin feature part. Depending on the type of profile, you can use tools such as Shell or Extruded Boss/Base to create thin features. Click Insert .To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, . Create a section of round bar stock. This is basically a round extrusion that has a .25in diameter and 10in length. You can use Extrusion, Sweep or any other method to create the base shape. Locate and activate the . Using the SOLIDWORKS Lofted Bend feature, you can create flat patterns to transition a square sheet metal opening down to round sheet metal opening.

ROUND PART FROM FLAT SHEET. I'm not sure if this can be done in sheet metal. I need to take a strip of metal, thin about .060 thick, 12 in long, 2 in wide, two holes in .If the part has an edge that is a straight line it should unfold. However the faces must be circular in section. If it is elliptical then it wont work. A potential issue is if the face wraps more than 360 .

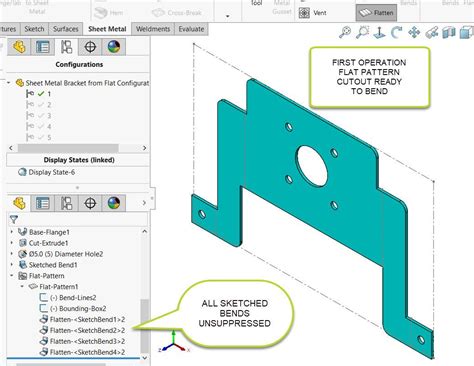

How To Model Complex Sheet Metal Parts in SOLIDWORKS. A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat .When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the .

swiss cnc machines for sale

To create a sheet metal part with round bends: Sketch a closed or open profile. Create a thin feature part. Depending on the type of profile, you can use tools such as Shell or Extruded .If you are just trying to make the curved section a piece of sheet metal then select a parallel plane to the two flats. Convert a line from one of the flat parts on the side you want the bent piece to be on. Make sure there is some small part of .geometries, the user has the option to use non-sheet metal feature tools and then use the Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude,Making a sheet out of it, and cut extruding circle forms from default top view. Looks correct but cut extrude messes up with flatten view which is needed for cnc. So i calculated the flattened ellipse dimensions that would form this circle when rounded up. I can then make a sketched bend in the middle and form it with 1774 as radius.

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of . Flatten Round Rod in Sheet Metal 1. Thread starter DylanR; Start date Jun 13, 2006; Status . and then do an Swept Cut to make the square part round. But when I do this the part loses it relations to the bend lines and won't go to a flat pattern anymore. . SolidWorks 06 4.1/PDMWorks 06 AutoCAD 06 ctopher's home (updated 06-21-05) Upvote 0 .Hi u/ThatsJeem, . This can be done using Sheet Metal functionality in SOLIDWORKS. Specifically the "Sketch Bend" command (GoEngineer - SOLIDWORKS: Sheet Metal Sketch Bend).I will caution you though that using Sketch Bends can be difficult if you want to make a full round bend like this as it must leave some amount, if only a sliver, of flat section on either side of the bend.

Bends in the sheet metal module must be sections of a cylinder. If your part meets that requirement, you can add a sketched bend. If it doesn't consider making a "forming tool" which should allow you to stamp a more complex shape. Do you need it to be sheet metal? You could just make a thickened surface

This part I have created is a 24" tall sheet metal transition (Loft-Bend) from a 48" Square to a 60" ID round with a metal thickness of .188". Our current manufacturing equipment limits me to making this part in 4ea quarter sections which we will weld together after formed on the press brake.

This part is a cone though so a simple conversion isn't going to work. The way I would do this is to use the imported geometry as a reference to make a native sheet metal part using lofted bend. I started by making new plane at each end using two endpoints and .Square to round sheet metal bend lines incorrect I am using Solidworks 2013 SP3.0. I am using the lofted bend feature to create a square-to-round adapter in custom dimensions (2-3/8" square and 4" round, 3" length) out of 16 gauge stainless.Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .Sketch a closed or open profile. Create a thin feature part. Depending on the type of profile, you can use tools such as shell or extrude to create thin features.. Click Insert Bends (Sheet Metal toolbar) or Insert, Sheet Metal, Bends.. In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the .

When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of .

SolidWorks doesn't allow to bend the flat sheet metal part into the round tube using Sheet Metal tools. I want it to be able to unfold into flat pattern properly, since it is physically possible. I've noticed earlier that SolidWorks doesn't .I'm modeling up some old parts from hand drawings from the 70's. One of the parts is bent from 1 inch plate, which makes me want to model it as sheet metal. As far as I can tell tho, SW will only let me cut the sheet metal perpendicular to the face, but I need to cut 5 deg from normal. Cutting at an angle just seems to make a larger normal cut.Hey, I'm working on a sheet metal part, and I'm having trouble getting a closed corner. I hope this makes sense; I have a corner with three bends, which means the flat pattern leaves it open. Attached is a photo of a manufactured bend that is closed. .

Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, then click OK to open a drawing sheet. Drag the Isometric view from the View Palette to the upper-right corner of the drawing sheet. In the PropertyManager: Under Scale, select Use custom scale. Type 1:3 to specify the scale.

Designing a part with sheet metal-specific features uses fewer features and editing tools, and eliminates the use of the rollback bar. The sheet metal-specific features make it easier and faster to create a sheet metal part than designing a part, then converting it to sheet metal.Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal. In the PropertyManager, under Sheet Metal Parameters, select the fixed face. Under Bend Edges, click Collect All Bends.

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .I'm an absolute 100% newbie to CNC plasma cutting, CAD, and solidworks. I tried Freecad, and Fusion 360, but Solidworks feels like it has just "clicked" for me, particularly with 3D parts, which is what most of my needs are. I've designed a few sheet metal parts, and I'm enjoying learning it. SolidWorks Lofted Bend Tutorial | SolidWorks Sheet Metal Cone Tutorial | Sheet Metal Transitions. This tutorial will teach you how to use lofted bend in Soli.

When creating a sheet metal part in SOLIDWORKS, one of the key features is the capability to “Flatten” the model into a sheet so it can be manufactured.This allows the manufacturing entity to have a flat pattern drawing derived from the created part. There may come a time when the product needs to be produced from round bar stock.

In a sheet metal part, create a new configuration. In the FeatureManager design tree, do one of the following: Right-click Flat-Pattern and select Unsuppress. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this .

76K subscribers in the SolidWorks community. ALL posts related to SOLIDWORKS are welcome. . Is there is a way to change the thickness of a sheet metal without modifying the dimensions of the part? Share Add a Comment. Sort by: . You can try using sheet metal gauge tables or setting your sheet metal thickness equal to a variable you create .

Solidworks - Tutorial on How to Draw a Square to Round Sheet Metal Transition using the Lofted Bend Feature

solidworks sheet metal shapes

Learn essential tips for beginners on how to stick weld thin sheet metal effectively. Discover the right gauge, techniques, and rod choices for successful welding.

making rounded parts from sheet metal solidworks|solidworks sheet metal cylinder