cnc grinding machine setting In this blog post, we will delve into the world of CNC grinding machine programming. We will explore the fundamental principles and techniques required to efficiently operate these machines. $17.49

0 · micromatic cylindrical grinding machine

1 · external cylindrical grinding machine

2 · cylindrical grinding machine manufacturers

3 · cnc internal grinding machine

4 · cnc grinding machine specifications

5 · cnc grinding machine manufacturers

6 · cnc end mill grinding machine

7 · cnc cylindrical grinding machine price

Flux core welding is an advanced welding technique that uses a special shielding gas to join metallic materials. Unlike gas metal arc welding (GMAW), flux core requires a shielding gas and the ability to arc weld without the need for an electrode.

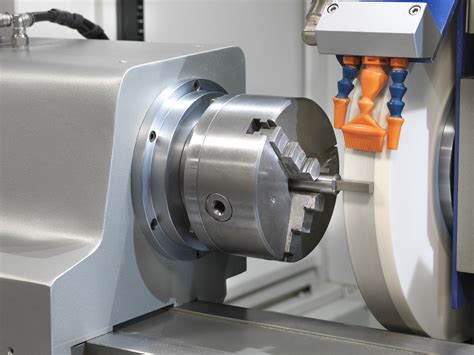

In CNC grinding machine setup, having the right tools and equipment is crucial for precision, efficiency, and safety. This section explores the indispensable tools that facilitate optimal machine operation and maintenance.CNC end face grinding involves using a rotating grinding wheel to remove .

Centerless Grinding Machine Process Operation For Round Pieces (Parts And Functions) Surface grinding on CNC GRINDER .more.

nema metal box

CNC, standing for Computer Numerical Control, is a grinding process prevalent in the manufacturing industry that leverages computer technology to govern machine tools. In the scope of our discussion, these .In this blog post, we will delve into the world of CNC grinding machine programming. We will explore the fundamental principles and techniques required to efficiently operate these machines. Today, we are working with Chris to show you all how to set up Studer ID for the best performance and programming on United Grinding. .more. CNC end face grinding involves using a rotating grinding wheel to remove material from the end faces of workpieces. The CNC system controls the movements and operations of .

Initial Setup: The setup phase involves preparing the CNC grinding machine and workpiece for the grinding process. It includes installing the appropriate grinding wheel, setting up the work-holding devices, and ensuring the machine is clean .

micromatic cylindrical grinding machine

In CNC grinding machine setup, having the right tools and equipment is crucial for precision, efficiency, and safety. This section explores the indispensable tools that facilitate optimal machine operation and maintenance. Centerless Grinding Machine Process Operation For Round Pieces (Parts And Functions) Surface grinding on CNC GRINDER .more.

CNC, standing for Computer Numerical Control, is a grinding process prevalent in the manufacturing industry that leverages computer technology to govern machine tools. In the scope of our discussion, these tools represent grinding machines designed to mold the workpiece in diverse manners.In this blog post, we will delve into the world of CNC grinding machine programming. We will explore the fundamental principles and techniques required to efficiently operate these machines.

Today, we are working with Chris to show you all how to set up Studer ID for the best performance and programming on United Grinding. .more.

CNC end face grinding involves using a rotating grinding wheel to remove material from the end faces of workpieces. The CNC system controls the movements and operations of the grinding wheel, ensuring precise machining according to programmed instructions.Initial Setup: The setup phase involves preparing the CNC grinding machine and workpiece for the grinding process. It includes installing the appropriate grinding wheel, setting up the work-holding devices, and ensuring the machine is clean and properly calibrated.

Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized. Nearly every CNC-related issue involves a parameter setting. Parameters specify settings for every CNC feature and function, and there are hundreds, even thousands, for any CNC.

A CNC grinding machine, or CNC grinder, operates automatically with minimum intervention from a machinist or operator. It follows programmed instructions to produce smooth surface finishes while reducing distortion and increasing the grinding process’s efficiency.In this blog post, we will explore the ins and outs of CNC grinding machine programming, covering the key concepts, codes, and techniques. Whether you are a beginner or an experienced CNC operator, this comprehensive guide will help you master the . In CNC grinding machine setup, having the right tools and equipment is crucial for precision, efficiency, and safety. This section explores the indispensable tools that facilitate optimal machine operation and maintenance.

Centerless Grinding Machine Process Operation For Round Pieces (Parts And Functions) Surface grinding on CNC GRINDER .more. CNC, standing for Computer Numerical Control, is a grinding process prevalent in the manufacturing industry that leverages computer technology to govern machine tools. In the scope of our discussion, these tools represent grinding machines designed to mold the workpiece in diverse manners.

new cnc lathe manufacturer

In this blog post, we will delve into the world of CNC grinding machine programming. We will explore the fundamental principles and techniques required to efficiently operate these machines.Today, we are working with Chris to show you all how to set up Studer ID for the best performance and programming on United Grinding. .more. CNC end face grinding involves using a rotating grinding wheel to remove material from the end faces of workpieces. The CNC system controls the movements and operations of the grinding wheel, ensuring precise machining according to programmed instructions.Initial Setup: The setup phase involves preparing the CNC grinding machine and workpiece for the grinding process. It includes installing the appropriate grinding wheel, setting up the work-holding devices, and ensuring the machine is clean and properly calibrated.

Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized. Nearly every CNC-related issue involves a parameter setting. Parameters specify settings for every CNC feature and function, and there are hundreds, even thousands, for any CNC. A CNC grinding machine, or CNC grinder, operates automatically with minimum intervention from a machinist or operator. It follows programmed instructions to produce smooth surface finishes while reducing distortion and increasing the grinding process’s efficiency.

external cylindrical grinding machine

cylindrical grinding machine manufacturers

nesting parts for cnc router

cnc internal grinding machine

ALLOY AND CARBON STEEL WEIGHT FORMULAS Shape Pounds per Foot Round Hexagon Square Flat D2 x 2.67 D2 x 2.945 D2 x 3.4 Thickness (in.) x Width (in.) x 3.4 WEIGHTS OF ALLOY AND CARBON BAR STEEL Per Linear Foot Sizes In Inches Round Square Octagon Hexagon Size In Inches Round Square Octagon Hexagon 1/16 5/64 3/32 7/64 .010 .017 .023

cnc grinding machine setting|cnc internal grinding machine