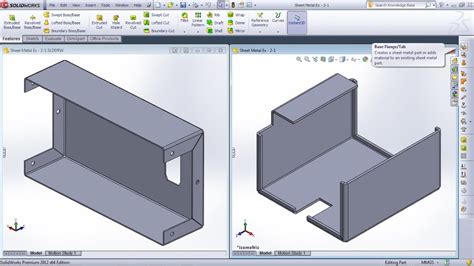

solidworks sheet metal part separate file Create new bodies in an existing sheet metal part using Base Flange, Convert to Sheet Metal, Insert Bends, and Lofted-Bend commands. Split a single sheet metal part into multiple bodies. . To protect the wires in the unprotected space, you use a short length of EMT from the crawlspace, through the floor, to the junction box. While people usually run separate THHN conductors through EMT, in this case it makes sense to use NM through the crawlspace and in to the EMT.

0 · solidworks sheet metal pdf

1 · solidworks sheet metal examples

2 · solidworks sheet metal drawing pdf

3 · solidworks sheet metal download

4 · solidworks sheet metal basics

5 · sheet metal modeling in solidworks

6 · sheet metal in solidworks 2021

7 · sheet metal 3d sketch solidworks

Wilsonart Steel Mesh 4879-38 4X8 Fine Velvet Finish Countertop Laminate Sheet $ 100.80 Top Cabinet Hardware Is Your One Source For Wilsonart Laminate Sheets, We Carry Their Full Line Of Beautiful Patterns & Designs At The Lowest Prices And Deliver It Promptly To Your Door Any Where In The USA.

To split a sheet metal part using the Split command: Open the part to be split. Create a sketch to be used to split the part. Select Split (Features toolbar). In the PropertyManager, under Trim Tools, select the sketch. Click Cut Part.

Right click on a body and Export to DXF/DWG (or save as and change the file type to DXF or DWG). Save the initial file, but then in the DXF/DWG Output dialog change the export type to .

Create new bodies in an existing sheet metal part using Base Flange, Convert to Sheet Metal, Insert Bends, and Lofted-Bend commands. Split a single sheet metal part into multiple bodies. .Is there a way to save bodies from a multi body sheet metal part as step files directly? Just my laser cutter also does my folding, and their NC brake press takes in Step files and calculates .One example where we would have a multi-body sheet metal part is a tank. Design the entire tank in a single file, then "cut" the panels into separate bodies/parts. We have a "base model" then .You can create a multibody sheet metal part using any command that creates multiple bodies from a single body. Use these commands on the Features

solidworks sheet metal pdf

Suppose you would like to split a multibody sheet metal part into separate files, how would you do this? I’ve found one proper discussion at the SolidWorks forum and the best that they could come up with is: Suppress all .

Now create a separate part file for the sub-weldment. Right-click the Sub-weldment1 folder and select Insert into New Part. For Solid/Surface Body , select each entity in the Sub-weldment1 . The SOLIDWORKS Split feature in SOLIDWORKS Sheet Metal allows you to break apart into multiple solid bodies without removing any material. You can use sketches, faces, planes and surfaces as tools to split parts into .

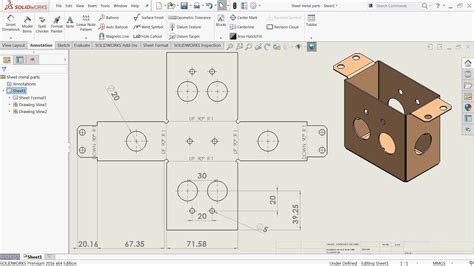

I can describe to you how to make a drawing for a multi-body sheet metal part. You’ll have to make a flat pattern view in the drawing for each body separately, SW will only allow a flat pattern to have 1 flat body in it. You’ve got .One example where we would have a multi-body sheet metal part is a tank. Design the entire tank in a single file, then "cut" the panels into separate bodies/parts. We have a "base model" then export each body to a separate file. We then convert the body to a sheet metal part. If we want to change something, we would edit the base model and the .

solidworks sheet metal examples

I have a macro from xarial, but only exports from assemblies files, individual parts. My multibody part is a bit large (125 different bodies, 100 is sheet metal parts), but is that is not a problem i think. If someone can help me, i will be grateful. And a macro that could separate thickness and material, would be awesome. Thanks in advance.

I need to do this because I don't trust the multi-body part and because it is a huge file (14 MB) with over 500 features and 14 unique parts. When I try to separate the files, I lose all features and it doesn't translate sketches, which I use for positioning other parts (not within the multi-body). . Separating multi-body sheet metal parts .You can map bend line directions to specific layers when you export sheet metal models as .dxf or .dwg files. For example, in sheet metal parts with up and down bend directions, you can map the different bend line directions to separate layers when you export the part.SOLIDWORKS File Utilities: DFMXpress: DriveWorksXpress: FloXpress: Import and Export: SOLIDWORKS MBD : . In addition, a cut list contains a separate representation for each body, with a flat pattern specific to the body. . where you can save the bodies in the multibody sheet metal part to individual files that you can use to create an assembly.SOLIDWORKS File Utilities: DFMXpress: DriveWorksXpress: FloXpress: Import and Export: . With a sheet metal part document open, click Insert Part (Features toolbar) or Insert > Part. . Expand the folder to edit the part. A cut list containing a separate folder for each body.

solidworks sheet metal drawing pdf

SOLIDWORKS File Utilities: Import and Export: Model Display: Mold Design: Motion Studies: Parts and Features: Routing: . You can specify the bend allowance or bend deduction values for a sheet metal part in a bend table. You can also specify K-Factor values in their own K-Factor bend tables. . You can edit a bend table in a separate Excel .When designing Sheet Metal parts in SOLIDWORKS, configurations are used to represent the folded and flattened states. . In the scenario where multiple variations of the same sheet metal part need to be revision managed independently, with unique lifecycles, individual flat patterns, and part numbers, separate part files should be used to .

You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. Creating Sheet Metal Flat Pattern Configurations. You .Stp files don't include the necessary information to convey that it is a sheet metal part. When you make sheet metal parts in OnShape or Solidworks, more information than just the 3D model is being created and processed. It's how these programs know that a bend is impossible or how to unfold. You need a more descriptive file or remake the model .

sdb999, I don't understand this comment: Additionally merge bodies is required for sheet metal, so an additional cut/extrude is needed to separate the twins. I deal alot with sheet metal. I have never had a problem creating a sheet metal flat pattern from a mirrored part. I do as Mandrake22 suggests, and in the mirrored part I Insert>Bends.

SOLIDWORKS File Utilities: DFMXpress: DriveWorksXpress: FloXpress: Import and Export: SOLIDWORKS MBD : . The Insert Part command lets you create a multibody sheet metal part by inserting a sheet metal body into another sheet metal part. . Expand the folder to edit the part. A cut list containing a separate folder for each body.Sheet Metal: Simulation: SimulationXpress: Sketching: SLDXML Data Exchange: . Use the Split feature to create multiple parts from an existing part. You can create separate part files, and form an assembly from the new parts. . or by assigning them to other stored part files. You can also allow SOLIDWORKS to attempt to assign all bodies to . I have a Part file which I have converted to Sheet Metal. I now have 40 separate sheet metal bodies in the part. I would like insert each body into a new part file, then make an assembly file from those 40 separate part files. Is there an easy way to batch insert sheet metal bodies into a new part? I have several sheet metal parts in a larger in context model and I do not want the PEM fasteners to be part of the larger BOM but I do want them in the BOM of each individual sheet metal part. So I saved all the sheet metal parts out as individual part files and added the PEM fasteners as derived parts. This is fine except the BOM does not .

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. Sheet-Metal is stored in the Sheet-Metal folder. Flatten-Bends1: Flatten-Bends represents the flattened part .In most situations, each and every body should be a separate part/file (Barring Configurations) and assembled in the Assembly. This is the case most of the time whether you're building sheet metal or other types of parts. Avoid multi-body parts unless you have a specific reason that requires multi-bodys.You can create a multibody sheet metal part by creating new sheet metal parts within an existing sheet metal part. You can add new sheet metal bodies using these commands: Base Flange/Tab; Convert to Sheet Metal; Insert Bends; Lofted-Bend; For all commands, when you finish adding the part, it appears as a separate body in the Cut list and a new .

solidworks sheet metal download

Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. Sheet-Metal is stored in the Sheet-Metal folder. Flatten-Bends1: Flatten-Bends represents the flattened part . First, right-click on the main face of your SOLIDWORKS Sheet Metal part and select Export to DXF / DWG. Next, save the DXF file with your desired file name and location. In the options, . Exporting our flat pattern to a DXF file directly from the SOLIDWORKS part file is incredibly simple. This process makes quick work of getting our .

SOLIDWORKS File Utilities: DFMXpress: DriveWorksXpress: FloXpress: Import and Export: SOLIDWORKS MBD : . In addition, a cut list contains a separate representation for each body, with a flat pattern specific to the body. . where you can save the bodies in the multibody sheet metal part to individual files that you can use to create an assembly.

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .SOLIDWORKS File Utilities: DFMXpress: DriveWorksXpress: FloXpress: Import and Export: . When you create a multibody sheet metal part, in the FeatureManager design tree, the main tree lists each body and its features in the order in which you add them. . In addition, a cut list contains a separate representation for each body, with a flat . Making a multibody sheet metal part is easy and useful. Some reasons you would make this type of part is if you are working with different gauges and different materials of sheet metal within the same part. . multibody part is a part in SOLIDWORKS that is made up of multiple solids and/or surfaces within the same part file. These bodies can .

Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. Sheet-Metal is stored in the Sheet-Metal folder. Flatten-Bends1: Flatten-Bends represents the flattened part .You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. Creating Sheet Metal Flat Pattern Configurations. You .

solidworks sheet metal basics

sheet metal modeling in solidworks

This aluminum alloy intake box hides away cables and wires to the camera and provides a secure, waterproof design. Main Features Aluminum Alloy Material with Surface Spray Treatment

solidworks sheet metal part separate file|solidworks sheet metal pdf