drawn sheet metal parts Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by .

Wires, receptacles and switches need adequate space. Crowded boxes can damage wires, resulting in a fire or shock hazard. You can use the chart below to calculate the required box size. Add up the numbers for the .

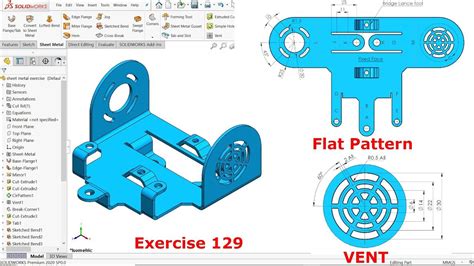

0 · solidworks sheet metal drawings

1 · simple sheet metal drawings

2 · sheet metal layout drawings

3 · sheet metal drawings with gd&t

4 · sheet metal command in solidworks

5 · sheet metal basic drawing

6 · sheet metal 3d sketch solidworks

7 · metal sheet riveted together drawing

Electrical code requires that all junctions be accessible in a box, so you definitely need one here. You have two choices (that I know of at least): cut a large hole in your siding and mount a retrofit light box into the wall cavity.

Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. It allows for superior quality components, produced at high speeds, and often at lower costs than competing methods.

1. What is deep drawing in sheet metal fabrication? Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. The depth of the drawn parts often . Have you ever wondered how a flat sheet of metal can be transformed into a complex, hollow part? Deep drawing, a fascinating forming process, makes this possible. In .Norpin Mfg. Co. Inc. is an industry leader of low and high volume manufacturing of precision fabricated & deep drawn sheet metal parts, deep drawn cans, cases, boxes, cups, caps, canisters, instrument housings and shells.

A how to guide for engineers and drafters designing sheet metal parts. Sheet metal parts often require multiple manufacturing processes to produce correctly. Because of this added complexity sheet metal drawings can be particularly .Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by .Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. [1] . It is thus a shape transformation . Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.

Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. It allows for superior quality components, produced at high speeds, and often at lower costs than competing methods. 1. What is deep drawing in sheet metal fabrication? Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. The depth of the drawn parts often exceeds their diameter. 2. . Have you ever wondered how a flat sheet of metal can be transformed into a complex, hollow part? Deep drawing, a fascinating forming process, makes this possible. In this article, we’ll dive into the intricacies of deep drawing, .

Norpin Mfg. Co. Inc. is an industry leader of low and high volume manufacturing of precision fabricated & deep drawn sheet metal parts, deep drawn cans, cases, boxes, cups, caps, canisters, instrument housings and shells.A how to guide for engineers and drafters designing sheet metal parts. Sheet metal parts often require multiple manufacturing processes to produce correctly. Because of this added complexity sheet metal drawings can be particularly tricky to create.Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to .Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. [1] . It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter.

Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts. The deep-drawing process converts a sheet metal blank into a cylindrical component with one side open.

Deep drawing of sheet metal is used to form parts by a process in which a flat blank is constrained by a blank-holder while the central portion of the sheet is pushed into a die opening with a punch to draw the metal into the desired shape without causing wrinkles or . Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. It allows for superior quality components, produced at high speeds, and often at lower costs than competing methods.

solidworks sheet metal drawings

1. What is deep drawing in sheet metal fabrication? Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. The depth of the drawn parts often exceeds their diameter. 2. . Have you ever wondered how a flat sheet of metal can be transformed into a complex, hollow part? Deep drawing, a fascinating forming process, makes this possible. In this article, we’ll dive into the intricacies of deep drawing, .

Norpin Mfg. Co. Inc. is an industry leader of low and high volume manufacturing of precision fabricated & deep drawn sheet metal parts, deep drawn cans, cases, boxes, cups, caps, canisters, instrument housings and shells.

A how to guide for engineers and drafters designing sheet metal parts. Sheet metal parts often require multiple manufacturing processes to produce correctly. Because of this added complexity sheet metal drawings can be particularly tricky to create.Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to .Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. [1] . It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter.

Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts. The deep-drawing process converts a sheet metal blank into a cylindrical component with one side open.

simple sheet metal drawings

union journeyman sheet metal worker salary

united metal fabricators exam table 4938

sheet metal layout drawings

When it comes to electrical wiring, not all metals are created equal. Some are superstars in conductivity, while others shine in durability or affordability. So, which metals often take center stage in this electrical .

drawn sheet metal parts|sheet metal basic drawing