electrical pull box purpose Proper installation of electrical pull boxes is crucial for several reasons. Firstly, it ensures the safety of the electrical connections by providing a secure and protected environment. Secondly, it allows for easy access to the . Short answer, yes they would. They need to ensure a) the outlet is live an b) the cable integrity is up to standard end 2 end. Not necessarily but it won't be an optimal install depending on the situation.

0 · when to use junction box

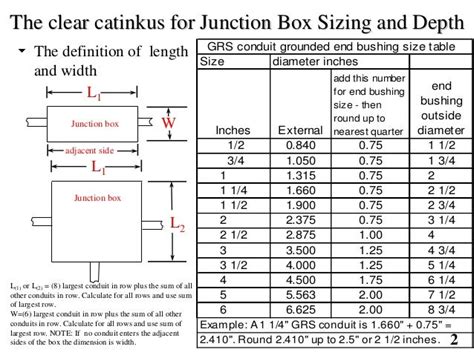

1 · pull box sizes chart

2 · pull box distance requirements

3 · maximum distance between junction boxes

4 · interior electrical pull box

5 · electrical pull box size chart

6 · distance between underground pull boxes

7 · different types of pull boxes

Yes, galvanized steel is usually magnetic because it’s made from mild steel coated with zinc. Does thickness affect magnetism? Yes, thicker metals are generally more likely to be magnetic.

Handholes, also known as underground enclosures or electrical pull boxes, are essential components of modern infrastructure. They provide easy access points for maintenance, inspection, and management of underground utilities like . Pull Boxes and Junction Boxes differences between pull boxes in electrical installations. Understand functions, sizes, and applications. A pull box describes an electrical box that gives access to pull electrical cables through non-metallic or metallic raceways and conduit. They give you a means to pull . Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances .

Proper installation of electrical pull boxes is crucial for several reasons. Firstly, it ensures the safety of the electrical connections by providing a secure and protected environment. Secondly, it allows for easy access to the .Pull boxes are used along with conduit to simplify wiring installation, hence their name. They are made of sheet metal, cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive .

Clear technical distinctions exist between junction boxes and pull boxes in electrical systems. These differences affect their applications, installation requirements, and .However, we are using electrical metallic tubing (EMT), and one engineer has informed us that all of the rules in NEC Chapter 3 for raceways, including boxes, apply. Do the rules for sizing a pull box in 314.28 apply because we are using .Discover the essential role of pull boxes in electrical installations, ensuring safety and efficiency. Learn about the types, components, and benefits of pull boxes, along with guidelines for proper installation and maintenance.In this article, we will examine the major differences between a pull box and a junction box, their purpose, and how each is used significantly. Read on! What is a Junction Box? A junction box is a small but essential part of any electrical system. It holds and protects electrical wire connections.

Handholes, also known as underground enclosures or electrical pull boxes, are essential components of modern infrastructure. They provide easy access points for maintenance, inspection, and management of underground utilities like . Pull Boxes and Junction Boxes differences between pull boxes in electrical installations. Understand functions, sizes, and applications. A pull box describes an electrical box that gives access to pull electrical cables through non-metallic or metallic raceways and conduit. They give you a means to pull conductors across an extended distance without putting too much tension on the cable or insulation. Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations.

Proper installation of electrical pull boxes is crucial for several reasons. Firstly, it ensures the safety of the electrical connections by providing a secure and protected environment. Secondly, it allows for easy access to the connections, .

when to use junction box

pull box sizes chart

Pull boxes are used along with conduit to simplify wiring installation, hence their name. They are made of sheet metal, cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive strain on the wire or insulation. Clear technical distinctions exist between junction boxes and pull boxes in electrical systems. These differences affect their applications, installation requirements, and overall project costs. Let's break down each type to help you make informed decisions.

However, we are using electrical metallic tubing (EMT), and one engineer has informed us that all of the rules in NEC Chapter 3 for raceways, including boxes, apply. Do the rules for sizing a pull box in 314.28 apply because we are using EMT?

Discover the essential role of pull boxes in electrical installations, ensuring safety and efficiency. Learn about the types, components, and benefits of pull boxes, along with guidelines for proper installation and maintenance.In this article, we will examine the major differences between a pull box and a junction box, their purpose, and how each is used significantly. Read on! What is a Junction Box? A junction box is a small but essential part of any electrical system. It holds and protects electrical wire connections.Handholes, also known as underground enclosures or electrical pull boxes, are essential components of modern infrastructure. They provide easy access points for maintenance, inspection, and management of underground utilities like .

Pull Boxes and Junction Boxes differences between pull boxes in electrical installations. Understand functions, sizes, and applications. A pull box describes an electrical box that gives access to pull electrical cables through non-metallic or metallic raceways and conduit. They give you a means to pull conductors across an extended distance without putting too much tension on the cable or insulation. Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations.

Proper installation of electrical pull boxes is crucial for several reasons. Firstly, it ensures the safety of the electrical connections by providing a secure and protected environment. Secondly, it allows for easy access to the connections, .Pull boxes are used along with conduit to simplify wiring installation, hence their name. They are made of sheet metal, cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive strain on the wire or insulation. Clear technical distinctions exist between junction boxes and pull boxes in electrical systems. These differences affect their applications, installation requirements, and overall project costs. Let's break down each type to help you make informed decisions.

pull box distance requirements

metal stair bracket

The quick answer is yes, you can use hot glue on fabric successfully as long as you follow some basic guidelines. The key is using the right type of hot glue and taking steps to reinforce the bond. What Fabrics Work Best with Hot Glue? When it comes to crafting or repairing fabric items, using hot glue can be a convenient option.

electrical pull box purpose|pull box distance requirements