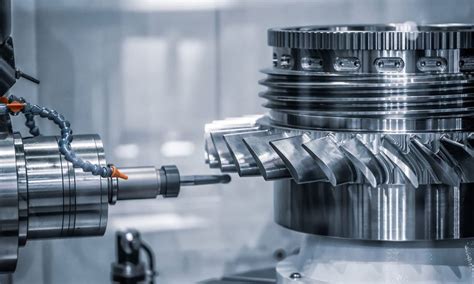

best aerospace cnc machining In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface .

Get the best deals for Twisted Metal Long Box at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

0 · machining aerospace parts

1 · cnc machining aerospace parts

2 · cnc aerospace parts

3 · aircraft cnc machining

4 · aerospace manufacturing cnc machining

5 · aerospace machinist

6 · aerospace cnc machining services

7 · aerospace cnc machine shop

There are seven main types of CNC machines: milling machines, lathes, routers, plasma cutters, laser cutting machines, drilling machines, and grinding machines. CNC technology combines computer control with traditional machining processes, resulting in high precision, efficiency, and automation.

By partnering with the right CNC machining supplier, you can elevate your aerospace manufacturing operations to new heights. A reputable supplier will not only provide state-of-the-art equipment but also offer valuable insights and expertise to help you optimize your production .

nema ratings for electrical enclosures

In the aerospace industry, CNC machining plays a crucial role in producing high . This guide delves into the intricacies of CNC machining tailored for aerospace applications, exploring the advanced techniques, specialized materials, and stringent quality standards that ensure the production of critical . Best CNC Machine Brands for Aerospace 1. DMG Mori. A titan in the CNC world, DMG MORI is renowned for its high-precision machines tailored for the aerospace sector. Their advanced 5-axis machining centers are adept .

machining aerospace parts

This article explains what aerospace CNC machining is and the typical materials used in aerospace manufacturing. You’ll also learn about precision and tight tolerances in aerospace machining, multi-axis CNC . In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface .

Aerospace CNC Machining creates strong, lightweight, and complex plastic parts for the aerospace industry. Making these parts include such materials as PEEK and other high-performance polymers. Similar to working .Precision machining in aerospace enables manufacturers to shape large pieces of material into more precise parts using computer numerical control (CNC) equipment.By partnering with the right CNC machining supplier, you can elevate your aerospace manufacturing operations to new heights. A reputable supplier will not only provide state-of-the-art equipment but also offer valuable insights and expertise to . This guide delves into the intricacies of CNC machining tailored for aerospace applications, exploring the advanced techniques, specialized materials, and stringent quality standards that ensure the production of critical components.

cnc machining aerospace parts

cnc aerospace parts

Best CNC Machine Brands for Aerospace 1. DMG Mori. A titan in the CNC world, DMG MORI is renowned for its high-precision machines tailored for the aerospace sector. Their advanced 5-axis machining centers are adept at handling intricate geometries, essential for aerospace components.

This article explains what aerospace CNC machining is and the typical materials used in aerospace manufacturing. You’ll also learn about precision and tight tolerances in aerospace machining, multi-axis CNC machines for aerospace parts, and suitable finishing options. Let’s dive in!

In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface treatments, and applications that make this technology so essential to the industry.

Aerospace CNC Machining creates strong, lightweight, and complex plastic parts for the aerospace industry. Making these parts include such materials as PEEK and other high-performance polymers. Similar to working with metals, aerospace machining offers the high precision needed for polymer-based aerospace applications.Precision machining in aerospace enables manufacturers to shape large pieces of material into more precise parts using computer numerical control (CNC) equipment. Five-axis machining isn’t simple in any industry, but it gets especially interesting in aerospace. With subtractive manufacturing, you must consider everything from material and workholding, to tooling and the toolpaths, to get to a finished part.CNC machining is especially beneficial for creating complex shapes and surfaces required in aerospace engineering. This advanced method of machining aerospace parts involves the automation of cutting, shaping, and drilling processes on the surface using pre-programmed computer software.

In the aerospace industry, CNC machining plays a crucial role in producing high-precision components for aircraft and spacecraft. CNC (Computer Numerical Control) technology is used to automate the manufacturing of complex parts, ensuring accuracy and consistency in every piece.By partnering with the right CNC machining supplier, you can elevate your aerospace manufacturing operations to new heights. A reputable supplier will not only provide state-of-the-art equipment but also offer valuable insights and expertise to .

This guide delves into the intricacies of CNC machining tailored for aerospace applications, exploring the advanced techniques, specialized materials, and stringent quality standards that ensure the production of critical components. Best CNC Machine Brands for Aerospace 1. DMG Mori. A titan in the CNC world, DMG MORI is renowned for its high-precision machines tailored for the aerospace sector. Their advanced 5-axis machining centers are adept at handling intricate geometries, essential for aerospace components.

This article explains what aerospace CNC machining is and the typical materials used in aerospace manufacturing. You’ll also learn about precision and tight tolerances in aerospace machining, multi-axis CNC machines for aerospace parts, and suitable finishing options. Let’s dive in! In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface treatments, and applications that make this technology so essential to the industry. Aerospace CNC Machining creates strong, lightweight, and complex plastic parts for the aerospace industry. Making these parts include such materials as PEEK and other high-performance polymers. Similar to working with metals, aerospace machining offers the high precision needed for polymer-based aerospace applications.

Precision machining in aerospace enables manufacturers to shape large pieces of material into more precise parts using computer numerical control (CNC) equipment.

aircraft cnc machining

Five-axis machining isn’t simple in any industry, but it gets especially interesting in aerospace. With subtractive manufacturing, you must consider everything from material and workholding, to tooling and the toolpaths, to get to a finished part.CNC machining is especially beneficial for creating complex shapes and surfaces required in aerospace engineering. This advanced method of machining aerospace parts involves the automation of cutting, shaping, and drilling processes on the surface using pre-programmed computer software.

aerospace manufacturing cnc machining

When devices are mounted in the box, the total conductor count must be increased by two for each mounting strap (not to be confused with ground wires). To put it simply, each current-carrying conductor (hot, neutral) .

best aerospace cnc machining|aerospace machinist