welding sheet metal blowing holes The problem with welding sheet metal or thin gauge steel is that you can easily . Beautiful Solid Zinc Sheet Shingles! We take ~22Ga Pure Zinc (not galvanized) and cut up to random widths 7"-10" wide and 16" long pcs. You can customize these dimensions for.

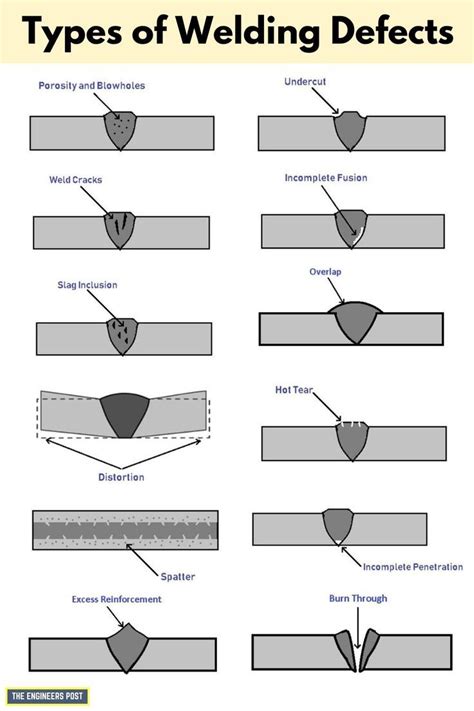

0 · welding defects photos

1 · weld defects chart

2 · overlap in welding defects

3 · how to prevent arc blow

4 · excessive penetration in welding

5 · blow hole welding defect

6 · arc blow is caused by

7 · arc blow diagram

$15.35

How to Avoid Blow-through When MIG Welding Sheet Metal. The quest for seamless body repairs eludes many DIYers when they face the menace of welder blow-through. The problem occurs when a weld penetrates completely through the material, either leaving a .The problem with welding sheet metal or thin gauge steel is that you can easily . I am a novice weldor restoring my 1953 MG YB. I'm finding that whenever I attempt to weld new metal to the old I am blowing holes in the old metal. I am scrupulously cutting out rust and grinding the surface clean.

Welding burn-through is a welding defect that can occurr when welding sheet metals, root run, and hot pass welding using any of the fusion welding processes. Weld Burn Through occurs when excessive heat is .

In this Video JD goes over why you should always keep a pack of copper backers in your welding cart! Welding sheet metal - blow through problems. 9 posts http://www.theathomewelder.com The Welding Tips Show episode 5 - How to avoid blowing holes in your metal when welding. To claim your free MIG Welding 101 co.

Here's a quick video on how to plug weld sheet metal using mig without blowing yourself a bigger hole than you started with. My names Matt Urch and I own an. In this follow up to an earlier video, David covers ideal machine settings, weld positions, and contact tip to work distance using Lincoln NR-211 self-shield. I will try to get into the details surrounding the topic and the different points of view related to stick welding sheet metal. . If you keep blowing holes in the work, dial down the amperage and try again. Some people also prefer whipping motion when it comes to welding thin . When starting to learn auto body sheet metal welding with a MIG welder, you should opt for a shielding gas that has a higher proportion of argon gas. It is better to use instead of a high percentage of CO2. . It will minimize your chance of committing any mistakes like warping and making a hole in the sheet down to 90%! So patience does pay .

This video is a tutorial on welding thin metal with the UNIMIG VIPER 185Email: [email protected]

welding defects photos

Have you ever welded something so thin and worn out that all you do is blow holes in it? Did you want to learn how to work around that and deliver a solid re. My only fear was blowing thru the sheet metal and making the hole bigger. Eastwood Mig135. Reply . 04-07-2014 #4. Burpee. View Profile View Forum Posts Find Started Threads . Read that from another sight while googling "welding sheet metal screw holes". Appreciate all the input! Reply . 04-07-2014 #10. Burpee. View Profile View Forum Posts .

can't screw in old work electrical box

Hey everyone, new to this board and have a newbie question. I am welding on an automobile project and having a little trouble. I am welding in some 16 guage sheetmetal to change the contour of the inner fenders, and the sheetmetal in the car is probably 18-20 guage. The problem I'm having is welding the 2 pieces together, I am blowing through the thinner stuff . In this video I show how to fill holes in sheet metal using a mig welder. This is always challenging do to the thin sheet metal cars are built out of today. . 40 amps stick is hot for sheet. You probably need to use a copper spoon behind it to be able to fill those blow holes that you will have. if you can keep the spoon attached to the face that you are welding you might keep the puddle from blowing out.

Mig and Flux Core - gas metal arc welding & flux cored arc welding . the pans are formed from 18 ga steel sheet with a thin galvanizing on them. . Saves me teaching all and sundry within earshot some new words, when unexpected holes appear in .Here is exactly how to weld without burning holes: Before you begin welding, read the company guidelines listed on the electrode packaging, the specifications included with your welder, and know the thickness and type of the metal you are welding. You need the correct amperage, the ideal electrode for the base metals, and proper techniques to . Hi all, I have been doing a few 'warm-up' practice welds (MIG) before I start in on my floor pans. I have been using both some old scrap floor pan pieces and pieces of 18 gauge sheet metal I have around the garage. I have been finding that quite often I end up blowing holes in the 18 gauge steel but not in the floor pan metal.

weld defects chart

1)use a piece of 1/8" rod without flux, clamp to work. Start arc on rod, not sheet metal. 2) Start arc on ground clamp(if brass) and moving to fill rod melting fill rod into sheet metal. 3) Use O/A torch, and direct heat to brazing .Also remember that sheet metal in general is pretty challenging even for experienced welders so don't beat yourself up to much if it takes some time. Plus flux core, generally speaking, is one of the most aggressive types of welding .

First time welding pipe in position and blowing holes through it Any input is appreciated! I think I'm too hot, fast, and dirty. . This isn’t far off from what I angle my torch at on thin sheet metal, spread that heat out parallel to the metal rather than directly into it, no more holes! I think your amperage is fine. 3. Adjust Your Torch Angle. Changing the torch angle when MIG welding goes a long way to preventing burn-throughs. Make sure you adjust the angle to shorten the distance between the tip and the metal, no matter the welding position you work in.This will make the arc more stable, giving you more control over the weld and lessening the chance of burn-through.

This's the best i can do for welding because the sheet metal 22 gauge and i know it too thin i sometime i end of blowing holes.. . As said above DON'T try and run a bead or you will end up blowing holes. Tack the piece in and weld lots of overlapped short bursts alternating around the patch. octo0072000 Member. Messages 6,006 Location south .

Get the 2 pieces as close together as possible with clamps, vice grips, sheet metal screws or even dent it if you have to. Cut the mig wire flush with the nozzle every time before you start, I like to start the weld on the frame rail in the centre . In this live video broadcasted on 10/12/16 Matt shows us how to fill holes in metal by TIG welding. TIG 200 AC/DC : http://www.eastwood.com/tig200acdc-53012..

The weld initially looks bad because of the slag from flux core welding. Spatter. Tiny beads of metal also get left behind after flux core welding which can create more grinding work. Porosity. You’ll get tiny holes or pockets of contamination in your weld. Blow out. This is when your sheet metal literally blows out the sheet metal into . If you have access to the back of the panel, you can hold a piece of sheet copper behind the hole and it will be easier to weld it up. I use magnets to hold the copper sheet to the back side of the panel. Normally the copper will not stick to the weld, but it will provide enough backing to keep the molten weld from blowing through.

Anyway, I’m welding several long fillets in .065 mild steel, but several of those fillets involve a gap of about 0.05 (I guess that makes it not a fillet.). In any case, trying to run these welds, I’m just blasting big holes in the material. I’ve modulated wirefeed and voltage (Hobart 190).

overlap in welding defects

The trouble is that at my lowest heat setting I continuously blow holes and make poor welds when attempting automotive sheet steel. The only thing I can think of would be that mayby I need the .023 wire for sheet metal. Some sheet metal welding advice would be appriciatted. Top. david_r. Re: Blowing holes in sheetmetal. Post by david_r » Sat . In welding, the term “blowing holes” refers to the formation of cavities during the welding process due to excessive heat or incorrect technique. 2. One reason for blowing holes when welding is the presence of impurities, such as rust or paint, on the surface of the metal.

canopy sheet metal parts nosing edge

cancer cure metal box

The best box spring should be flat, level, and built to keep your mattress in tiptop shape; and that’s just what the Smart BoxSpring® does! With its reliable steel structure, you can rest assured that your mattress will be sitting pretty.

welding sheet metal blowing holes|arc blow is caused by