welding sheet metal to steel In this article, I am going to explain the fundamental ways of how to weld sheet metal that even professionals can follow. I have also put together a list of best welders for . The term "gauge steel" is often used to refer to the thickness of sheet metal made of steel. Understanding these nuanced differences is vital when consulting a metal gauge chart to ensure that you're selecting the appropriate .

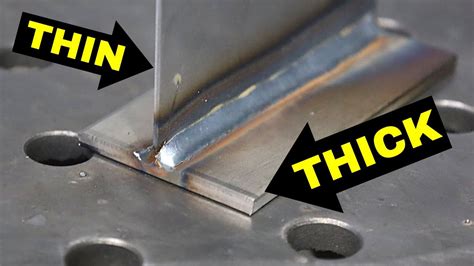

0 · welding thin to thick metal

1 · welding 14 gauge sheet metal

2 · welder settings for sheet metal

3 · welded sheet metal manufacturing

4 · sheet metal welding methods

5 · best welding for thin metal

6 · best welder for sheet metal

7 · 18 gauge weldable sheet metal

Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material.

Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See moreNow that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See more

Welding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these . In this article, I am going to explain the fundamental ways of how to weld sheet metal that even professionals can follow. I have also put together a list of best welders for .

Master the art of how to weld sheet metal with our comprehensive guide. Learn safety, techniques, best practices, and tips for welds. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm). In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we.

Here, we’ll explore the sheet metal welding methods we use in our shop and explain what to expect from each one. Table of Contents. 1 Spot Welding. 1.1 Considerations for spot welding. 2 Tack Welding. 2.1 . Welding sheet metal can be difficult. This 2 part video explains & demonstrates the basic techniques and tips for first time sheet metal welders. LINK TO BUY. When welding sheet metal, precise control and attention to detail are vital for successful welds. Understanding the distinct approaches of MIG and TIG welding is essential for working with materials like steel or aluminum, .

There are five common welding approaches for sheet metal, including TIG, MIG, Stick, Laser beam & plasma welding. What is the thickness limit for sheet metal welding? O.8 mm is the lower thickness limit for sheet .

welding thin to thick metal

Welding thin sheet metal can be challenging because you need to obtain adequate fusion while preventing distortion and burnthrough. The key skill is to control the heat across the sheet metal to prevent defects. This guide .Most of the light gauge sheet metal work will require the use of .023- or .24- inch while if you have a sheet metal having a gauge of more than 18-gauge then a .030-inch wire would be the most ideal. A ER70S-6 wire would be most ideal .Acrux7 16 PCS Butt Welding Clamps, Small Sheet Metal Clamp, Carbon Steel Panel Clamps for Auto Body Edge to Edge Welding (1x2.3 Inch) 4.6 out of 5 stars. 11. . QWORK 10" Nickel Plated High Carbon Steel Locking Sheet Metal Clamp, 2-Pack with Trigger Release and Adjustable Mechanism for Metalworking, Adjustable Opening Nickle Plated Welding Plier. In this comprehensive guide, we'll delve into the intricacies of MIG welding sheet metal and explore the ideal settings for different metal thicknesses. From. . While carbon dioxide (CO2) is commonly used for welding steel, a mixture of argon and carbon dioxide (often referred to as C25) is preferred for welding stainless steel or aluminum .

To braze weld sheet metal, first, clean the metal surfaces, apply flux, heat the metal, and then apply the brazing rod. Braze welding can be done with a . Sheet metal comes in different types such as stainless steel, aluminum, copper, brass, and carbon steel. Each metal type has unique properties and requires specific welding or brazing . The Hobart Handler 140 is an excellent choice for sheet metal welding due to its versatility and user-friendliness. With an amperage range of 25 to 140A, it’s capable of handling various thin materials, including sheet metal. . Whether you’re welding thin carbon steel or folding sheet metal into intricate shapes, it’s essential to .

I'm creating a metal frame out of 2" square steel tubing (16ga). Then I want to attach a sheet of 16ga sheet metal to the back (no welding). I'm going to fill the inside of the frame with wood to make a door.

Preparing the Sheet Metal for Plug Welding Sheet Metal. Before initiating the plug welding sheet metal process, it’s imperative to prepare the sheet metal to ensure optimal weld quality and structural integrity. The following steps outline the essential preparations for achieving successful plug welds: Sheet metal welding is a vital aspect of manufacturing. Read on to learn the different welding methods for the sheet metal parts. . such as aluminum, steel, and stainless steel. This welding method is the go-to technique in the automotive and home improvement industry. Also, it is a cost-effective technique, as it requires no sophisticated . Sheet metal welding is a crucial fabrication process because it is one of the simplest ways to join cut-out pieces of metal sheets to create the desired shape. . Because it creates strong joints in steeliness steel & non-ferrous sheet metal like Aluminum, copper, titanium, magnesium, and Chromium, TIG welding is widely applied in the . If you are welding sheet metal, make sure the equipment you are using is designed for welding sheet metal. You should also make sure that the position you are welding from is clear of other metal parts. Summary of How To Weld Sheet Metal On A Car. Wet welding is the process of sticking metal components together with melted metal.

Can You Weld 22-Gauge Sheet Metal? You can weld a 22-gauge (0.03-inches) metal sheet using a TIG welder or even with a MIG welding unit. However, it is not recommended to stick weld 22-gauge sheet metal as excessive penetration is highly likely to occur and become problematic. The 16 gauge or 1.5mm is a safe bottom limit for material thickness .Thin to thick, here's the trick!Learn faster with an online welding course: https://courses.timwelds.comOther Helpful Videos: MIG Welding Settings: https://y.I will try to get into the details surrounding the topic and the different points of view related to stick welding sheet metal. . If you are looking to work on mild steel, for example, the 6013 rods would be suitable for the job, make sure you are selecting a thin rod. The 0.093” would do the job, even thinner than that would be better. Welding sheet metal with a stick welder is a bit more challenging, especially when welding thin sheets of metal. The heat input in stick welding is generally . E6011 is commonly used as an all purpose electrode for .

Get the J-B Weld glue for metal at Amazon, The Home Depot, Grainger, or J-B Weld. . Setting and curing times: Sets in 5 minutes and is steel hard in 15 minutes; fully cures in 1 hour; Welding autobody panels. Auto body sheet metal is relatively thin, and this can present some challenges for welders particularly those who are accustomed to welding thicker materials. Welding nearly always causes some .

Induction welding; Welding Sheet Metal. For welding purposes, the term “sheet metal” is restricted to thicknesses of metals up to and including 1/8 in. (3.2 mm). Welds in sheet metal up to 1/16 in. (1.6 mm) thick can be made satisfactorily by flanging the edges at the joint. The flanges must be at least equal to the thickness of the metal. To weld sheet metal you need a tig or mig with the gas bottle. These to welder you can weld at lower temps. . needed when welding thin stock..Very seldom is one going to be able to use a continous weld like we use in structrual steel when welding thin body metal with any kind of equipment.. Sam . Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, . Sanitary Welding Stainless Steel: Ensuring Top-Quality Hygiene; Best Aluminum Welder For Beginners: Top 5 Picks & Reviews; Arc Welding Vs Tig Welding: Ultimate Guide to Choosing the . The brazing alloy has a much lower melting point than steel, so you need to heat the pieces to a lower temperature than you would when welding. To get to the right temperature for brazing, which is usually 800–2,000 degrees Fahrenheit depending on the alloy, you can use equipment that is not as powerful as a welding machine, including propane .

#welddotcomWe are still working through your requests that were submitted through our Instagram story. @bostonrush77 asked us to show how to do old rusty she. Gas welding sheet metal is a great way to join two pieces together quickly and efficiently without having to rely on traditional methods such as soldering or brazing. With the right tools and know-how, however, anyone can become a master at gas welding sheet metal in no time! . How to Gas Weld Mild Steel – A Complete Guide. Similar Posts .

However, some practical advice might help you with higher gauge sheet metal. Stick Welding Equipment To Weld Thin Metal Like other welding methods, you won't need the most powerful Stick welder to weld thin sheet metal. Instead, you can do it with a YesWelder ARC-125DS DC Stick welder, rated at 20-125 amps with an easy arc start technology.How To Weld Sheet Metal The RIGHT WAY - SUPER EASY#howto #diy #welding My Friend Pete shows us the easiest and simplest way to weld sheet metal. From butt w. Metal is commonly used to create strong and durable structures, but welding may not always be the best option for bonding two pieces of metal. Welding requires special equipment and expertise, and can be time-consuming and expensive. Fortunately, there are alternative methods for effectively bonding metal without welding. Industrial adhesives . Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld.

welding 14 gauge sheet metal

The little ears on outlets and light switches are used in conjunction with “new work” electrical boxes — “new” referring to new construction, where the box is affixed to the studs in new, bare framing before drywall has been installed.

welding sheet metal to steel|welded sheet metal manufacturing