fabrication metal sheet stamping Sheet metal fabrication and its intricate processes are always in my mind when I reflect on our experience at Shengen.Sheet metal stamping is one of the techniques crucial to our success. We’ll explore this vital technique together. .

With a bit of practice, you should be able weld 11 gauge all day with stick. 11 ga. is ~1/8" thick, that's plenty of metal to work with. Smaller rod is always preferred, but in a pinch, I have even welded 11 gauge with 1/8" 7018 (at about 105 amps) before with professional looking results.If you have a set of calipers you can measure the thickness of the existing metal and then order what you need. Here's some of the common gauges and corresponding thickness of sheet steel: GA.

0 · wholesale custom sheet metal stamping

1 · sheet metal stamping near me

2 · sheet metal stamping design guidelines

3 · sheet metal stamping basics

4 · sheet metal stamping at home

5 · metal stamping service near me

6 · metal stamping process flow chart

7 · automotive sheet metal stamping process

To become a Sheet Metal Worker, formal education is required. Most Sheet Metal Workers have a high school diploma or equivalent, and some vocational or technical training in sheet metal work.

Understanding the steps in the sheet metal stamping process demonstrates how high-quality components are produced, guiding businesses toward informed decisions and efficient .Explore our in-depth guide on metal stamping, covering key processes, materials, precision techniques, and comparisons with CNC machining. Learn about surface finishes, die types, and how to select the best supplier for custom metal .Custom Sheet Metal Fabricator & Metal Stamping Company. Delivering premiere sheet metal fabrication services, short run stampings, and assemblies for industries nationwide since 1972. Request a QuoteSheet metal stamping is one of the techniques crucial to our success. We’ll explore this vital technique together. The sheet metal stamping process is where metal sheets can be shaped and sized to the desired shape or size by .

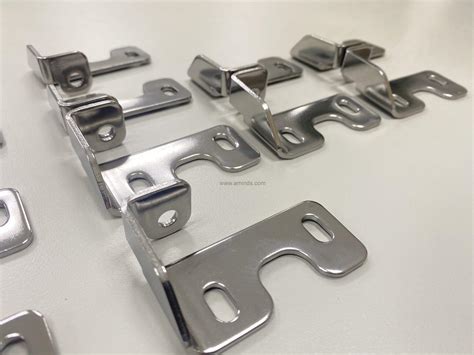

Sheet metal stamping is a fabrication process that uses dies, punches, and other tools to bend, cut, punch, flange, or otherwise shape the sheet metal into the end component. This method is a cost-effective option for large production runs .

Sheet metal fabrication and its intricate processes are always in my mind when I reflect on our experience at Shengen.Sheet metal stamping is one of the techniques crucial to our success. We’ll explore this vital technique together. .From its beginning in a basement shop to its present 87,720 square foot facility, we at the James F. Mullen Company have worked hard to acquire the strong reputation as a customer oriented, quality conscious and cost competitive company.Method: Precision Sheet Metal Fabrication / Low Cost Tool Description: 11” X 6” Material: CRS ANN 060 (16 ga ) Equipment Used: Flat Bed Laser, Press Brake, Some Custom Tooling. Note: Combined Laser, Sheet Metal Fabrication with .

A Leading Manufacturer of Metal Stamping, Sheet Metal Fabrication. LIKE HOLDS BOTH ISO 9001 AND ISO 14001 CERTIFICATIONS! Custom Precision Metal Stampings, Casting Metal, Deep Drawn Stamped Parts and Fabrication – 20 Years of .

Dunkirk Metal Products is a leading provider of custom sheet metal fabrication and stamping services in Pittsburgh PA area.. The company began operations in 1947 in Dunkirk, NY and was acquired by 3 local businessmen in 2012 who brought a renewed focus on the company’s history of commitment to customer service and quality operations.Stamping. Stamping uses stamp presses to cut and mold metal sheets into a desired shape. Like punching processes, the stamping process comes with benefits and disadvantages. The initial cost to set up a custom metal stamping job is substantial and is generally related to the size and complexity of the design.Our facilities leverage various presses from 30 to 400-ton capacity to produce a wide range of custom metal stamping parts. The metallurgical expertise we use to design our spring and fastener products also extends to stampings, allowing our engineers to create components utilizing materials from low-carbon steel to pre-tempered alloys in thicknesses from .004″ to . Editor's Note: This series presents an overview of metal stamping. Part I focuses on the various careers in the metal stamping industry. Part II discusses stamping materials and equipment. . Sheet Metal Stamping 101 Parts I - V. By Art . The magazine delivers the news, technical articles, and case histories that enable fabricators to do .

When you need nondestructive testing with results in seconds for metal analysis, mining and exploration, and lead paint testing for toys and consumer goods, the Thermo Scientific™ Niton™ XL2 Plus XRF Analyzer is the definitive tool for scrap metal recycling, casting and fabrication, manufacturing QA/QC and positive material identification. Hangzhou MH Metal Fabrication Co., Ltd.: We're known as one of the most professional sheet metal fabrication, tube fabrication, metal stamping, container homes, steel tube fabrication manufacturers and suppliers in China. If you're going to buy high quality products with competitive price, welcome to get more information from our factory. Also, custom service is .Similar to progressive stamping, but instead of the metal sheet moving continuously through the dies, mechanical systems transfer the sheet from one station to another. . Metal stamping made it possible for the precise fabrication of intricate parts required for electronic assemblies while ensuring proper electrical conductivity and .We specialize in short run metal stamping and medium run metal stamping and promise to provide the best quality every time. Custom Metal Stamping For Any Material Winco’s state-of-the-art facility allows us to provide precision metal stamping manufacturing with various kinds of metal, including:

Our Capabilities: Sheet Metal Fabrication, CNC Machining, Metal Stamping FZ Metalwork Co., Ltd. China Custom Metal Parts Manufacturer with more than 20 years experience. . Products produced through sheet metal processing, metal stamping, and CNC machining. Stamping Parts 2. 2022 08-29. CNC Parts 2. 2022 08-29. Stamping Parts 1. 2022 08-29 .

wholesale custom sheet metal stamping

sheet metal stamping near me

Agwey Metal Designs, Inc. offers custom metal stamping, precision sheet metal fabrication, and waterjet cutting services. Search. Skip To Content. [email protected] 508.747.1037. 508.747.1037 [email protected] RFQ. About Us; Capabilities. Custom Metal Stamping Service;

Fabrication made sense at the beginning to get the initial parts to market, but once the tooling was built, stamping was the more cost-effective option. 10,000 parts is usually the threshold that many companies use when .

Metall Metal is an ISO9001 Certified company in metal stamping, sheet metal fabrication, sub-assembly and assembly for multiple industries in China. LinkedIn Email: [email protected] Phone: +86 21 67681119

Sheet metal pressing, also known as fabrication metal sheet stamping or sheet steel pressing, offers several advantages over other metal forming processes. One of the major advantages is the ability to produce high-quality metal parts .

Xometry offers the following materials for both our standard and custom metal stampings: Steel: CRS steel like 1008, 1010, or 1018 is popular; general-purpose material is perfect for cold forming.; Stainless Steel: such as 301, 304, and 316/316L. 301 stainless steel has excellent tensile strength, while 304 has more significant performance and corrosion resistance at higher .Start to Finish Metal Stamping Fabrication All-New can work with any sheet metal stock from .001-.250” thick, including, steel, stainless steel, copper, brass, aluminum and even rigid plastic. Metal Stamping Capabilities. We can fabricate parts as large as 48”x 48”.Dunkirk Metal Products is a leading provider of custom sheet metal fabrication and stamping services in Columbus OH area. The company began operations in 1947 in Dunkirk, NY and was acquired by 3 local businessmen in 2012 who brought a renewed focus on the company’s history of commitment to customer service and quality operations.Sheet metal stamping is the process of turning sheet metal into specific shapes. During the manufacturing process, sheet metal is fed into a press brake where it is shaped by a tool and die. The tonnage, or amount of pressure applied by the press, needed is determined by the type of metal and the desired shape.

We offer hybrid manufacturing; CNC fabrication, metal stamping, or a mix of both processes to reduce unit costs.Fewer than 5% of fabricators offer this. Unlike most suppliers, we are not tied to a single fabrication method. Based on the complexity and annual volumes of each part, we will seamlessly migrate you from CNC fabrication, to hybrid manufacturing, to metal .Sheet Metal Fabrication - Sheet Metal Stamping - Laser Cutting - CNC Machining - MA . • Sheet Metal Fabrication • Sheet Metal Stamping • Laser Cutting • CNC Machining • Basic Tool Making • Punching • TIG, MIG & Spot Welding • Shearing • PEM Hardware • Forming & Bending

Metal Stamping with Automated steel punches are capable of making hundreds of precisely-spaced holes in sheet metal. About Us. About Us . Sheet Metal Fabrication; Translate This Page. Marlin Steel Wire Products . 2648 Merchant Drive Baltimore, MD .Sheet metal stamping is one of the most basic and critical sheet metal fabrication services. It uses punches and dies to process iron, steel, copper, aluminum, and other metal sheets into the required parts through punching, spinning, bending, deep drawing, drawing, expanding, flanging, and shrinking. . Sheet metal fabrication service is a .Shanghai Yixing is a leading manufacturer of customized sheet metal parts in China, established in 2003, with over 5000 square meters of facilities, serving more than 1000 customers around the world and the industries we serve include household appliances, automobiles, motorcycles, buildings, lighting, healthcare, energy and power transmission, furniture, electronic industry, .

Sheet metal stamping is a versatile and efficient manufacturing process employed by companies like Neway to create precise and complex metal components. This method uses dies and punches to shape flat metal sheets into desired forms. . Sheet metal fabrication is a versatile manufacturing process that involves shaping metal sheets through .

sheet metal stamping design guidelines

sheet metal stamping basics

A Spider Box is a portable power distribution box that is designed to be an economical way to distribute electrical power using a 250 VAC, single-phase power source. Typically, spider boxes are used to power tools and other equipment on construction sites, in disaster recovery efforts, and any other application where temporary power is needed.

fabrication metal sheet stamping|automotive sheet metal stamping process