cnc machine hour rate calculation pdf A machine hour rate is a costing method used by businesses to calculate the cost of running and maintaining a particular machine for one hour of operation. It takes into account various expenses such as depreciation, maintenance, electricity, . A concrete distribution box is the traffic director of your septic system. It’s critical for managing the flow of wastewater from the septic tank to your drain field. This box ensures that effluent is evenly distributed across the drain field, preventing overloading and .A septic distribution box, also known as a D-box, is a crucial component of a septic system. Its primary function is to receive the effluent (wastewater) from .

0 · machinery cost per hour calculator

1 · machine hour rate calculation formula

2 · machine hour rate calculation excel

3 · machine cost per hour formula

4 · cnc router cost per hour

5 · cnc milling cost per hour

6 · cnc machine cost per hour

7 · calculating machine cost per hour

Here we'll discuss fiberglass and spray foam insulation which are both appropriate for adding insulation to an existing roof. Also, we'll discuss rigid foam board insulation which is most appropriate for insulation during construction.

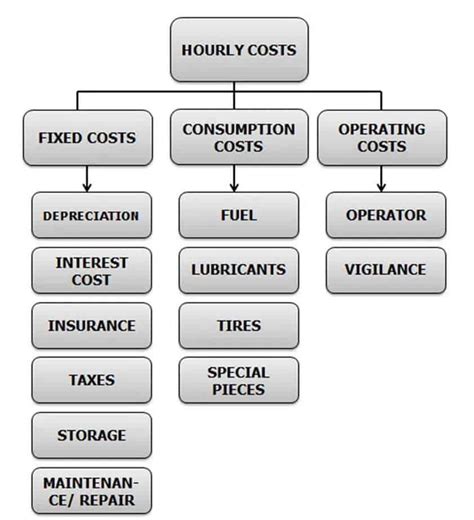

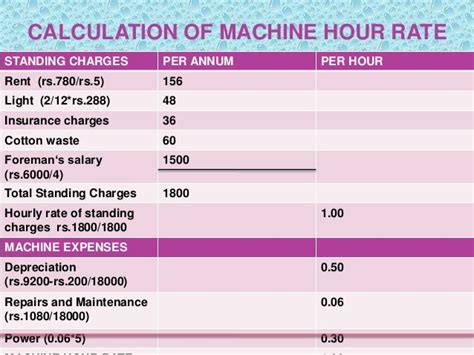

As explained earlier, Machine hour rate is the overhead rate for one hour of machine worked. The first step in the computation of machine hour rate is the departmentalisation of overheads. i.e., . Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs. A machine hour rate is the hourly cost in terms of factory overheads to operate a particular machine. It is obtained by dividing the factory expenses associated with the machine for a given period by the number of hours worked .

A machine hour rate is a costing method used by businesses to calculate the cost of running and maintaining a particular machine for one hour of operation. It takes into account various expenses such as depreciation, maintenance, electricity, .Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, .To accurately estimate the cost of CNC machining, it is essential to calculate the machine hour rate effectively. This calculation takes into account various factors such as labor costs, .This guide will walk you through the step-by-step process of determining the hourly rate for your CNC machine, considering various factors that can affect the cost. So, let's dive in! Chapter 1: .

MEANING: - Machine hour rate (MHR) is the cost of running a machine for one hour. Under this method machines hours are used as the basis for production overhead absorption rate. The rate is calculated as follows: Suitability: - This method is suitable where major portion of production is performed by machinery. It takes into account time factor.

machinery cost per hour calculator

As explained earlier, Machine hour rate is the overhead rate for one hour of machine worked. The first step in the computation of machine hour rate is the departmentalisation of overheads. i.e., apportionment of overheads costs of service departments to production departments.Machine Hours Rate: Formula, Calculation, Problems and Solutions! The machine hour rate is similar to the labour hour rate method and is used where the work is performed primarily on machines. The formula used in computing the rate is: Factory overhead/Machine hours. Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs. A machine hour rate is the hourly cost in terms of factory overheads to operate a particular machine. It is obtained by dividing the factory expenses associated with the machine for a given period by the number of hours worked by the machine during that period.

A machine hour rate is a costing method used by businesses to calculate the cost of running and maintaining a particular machine for one hour of operation. It takes into account various expenses such as depreciation, maintenance, electricity, and labor costs associated with the machine.

machine hour rate calculation formula

Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, businesses can make informed decisions on pricing, cost optimization, and overall profitability.To accurately estimate the cost of CNC machining, it is essential to calculate the machine hour rate effectively. This calculation takes into account various factors such as labor costs, machine depreciation, overhead expenses, and material costs.

This guide will walk you through the step-by-step process of determining the hourly rate for your CNC machine, considering various factors that can affect the cost. So, let's dive in! Chapter 1: Understanding CNC Machine Hour Rate\ 1.1 What is CNC Machine Hour Rate?\ 1.2 Importance of Calculating Hourly Rates\

The document provides details on calculating machine hour rates, classifying overhead costs, and the advantages and disadvantages of using this overhead absorption method.MEANING: - Machine hour rate (MHR) is the cost of running a machine for one hour. Under this method machines hours are used as the basis for production overhead absorption rate. The rate is calculated as follows: Suitability: - This method is suitable where major portion of production is performed by machinery. It takes into account time factor.

As explained earlier, Machine hour rate is the overhead rate for one hour of machine worked. The first step in the computation of machine hour rate is the departmentalisation of overheads. i.e., apportionment of overheads costs of service departments to production departments.Machine Hours Rate: Formula, Calculation, Problems and Solutions! The machine hour rate is similar to the labour hour rate method and is used where the work is performed primarily on machines. The formula used in computing the rate is: Factory overhead/Machine hours. Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs.

https www.dapramarking.com direct-part-marking scribe gravostar-cnc

A machine hour rate is the hourly cost in terms of factory overheads to operate a particular machine. It is obtained by dividing the factory expenses associated with the machine for a given period by the number of hours worked by the machine during that period.A machine hour rate is a costing method used by businesses to calculate the cost of running and maintaining a particular machine for one hour of operation. It takes into account various expenses such as depreciation, maintenance, electricity, and labor costs associated with the machine.

Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, businesses can make informed decisions on pricing, cost optimization, and overall profitability.To accurately estimate the cost of CNC machining, it is essential to calculate the machine hour rate effectively. This calculation takes into account various factors such as labor costs, machine depreciation, overhead expenses, and material costs.This guide will walk you through the step-by-step process of determining the hourly rate for your CNC machine, considering various factors that can affect the cost. So, let's dive in! Chapter 1: Understanding CNC Machine Hour Rate\ 1.1 What is CNC Machine Hour Rate?\ 1.2 Importance of Calculating Hourly Rates\

huntsville al sheet metal

machine hour rate calculation excel

At its core, a CNC woodworking machine is a computer-controlled device that uses specialized software to precisely cut, shape, and carve wood materials. Unlike traditional woodworking tools that require manual manipulation, a CNC machine operates through programmed instructions, allowing for unmatched precision, repeatability, and efficiency.

cnc machine hour rate calculation pdf|machine hour rate calculation excel