sheet metal strengthening techniques Sheet metal is one of the most common metal forms used in metalworking applications. This is because it is strong, lightweight, and non-corrosive. . Here are techniques used to strengthen thin metal strips. 1. . While electrical boxes have many variations, they all fall into one of two categories: plastic boxes or metal boxes. Sometimes, the choice is clear-cut and obvious, mainly for grounding. Other times, it's a matter of personal .

0 · sheet metal strengthening

1 · sheet metal stiffening techniques

2 · how to strengthen sheet metal parts

3 · how to make sheet metal better

4 · how to improve sheet metal parts

5 · how to improve sheet metal

6 · how to do sheet metal

7 · best way to strengthen sheet metal

The fuse box is located in the glove box and under the hood on the driver side above the batterie Where is the ECM located in a 1999 Chrysler New Yorker? The last Chrysler New Yorker was made in 1996.

For sheet metal parts to be durable and reliable, metal strengthening, sometimes referred to as stiffening, is essential. It entails incorporating structural support to stop pieces from warping and failing under .

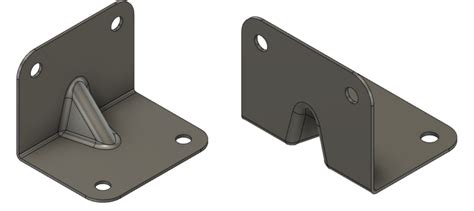

Here we explore six methods to add structure to sheet metal, helping ensure your project posseses both strength and functionality. Bending This process is commonly used in forming various components such as .

sheet metal strengthening

sheet metal stiffening techniques

Consider material and finishing options along with design elements like bends, reliefs, holes, and slots when developing sheet metal components. By combining these two techniques, you can easily strengthen sheet metal parts and create attractive designs. Another way to reinforce sheet metal parts is by folding the edges. This will give them an instant structural integrity and minimize the likelihood of deformation. . Another way to strengthen sheet metal is through the use of rivets . Sheet metal is one of the most common metal forms used in metalworking applications. This is because it is strong, lightweight, and non-corrosive. . Here are techniques used to strengthen thin metal strips. 1. . Advanced Sheet Metal Exercise in Solid Edge👉For more Tutorials, please visit: https://www.youtube.com/c/CADCAMLearning?sub_confirmation=1------ .

SHEET METAL CAD EXERCISES - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document lists 40 sheet metal CAD exercises numbered from 1 to 40 without providing any details about the content or objectives of each individual exercise. The exercises are presented in a list format without paragraphs or descriptions. When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. . The primary reason for taking production time to stiffen and strengthen duct is compliance. SMACNA sheet metal standards deem that ductwork of various gauges should be put through a stiffening process .Practice Exercise – Bracket Basic Sheet Metal Exercises, SOLIDWORKS Sheet Metal Page 1 Summary: In this exercise, you’ll create a sheet metal bracket. You’ll use a combination of different flange features to create the base and utilize sheet metal features to finish the part. Reference Lessons: Sheet Metal and Flat Pattern Features Stretching is the process of extending the metal sheet in a certain direction. This process strengthens the sheet metal by orienting the metal’s grain in a certain direction. It also adds an aesthetic aspect to your sheet metal design. Stretching can be easily achieved by adding embosses, such as a formed punch or beaded emboss.

To meet unique sheet metal design challenges like manufac-turability, Solid Edge streamli-nes the entire sheet metal product development process, from CAD design through flat pattern and drawing development. Unlike general-purpose CAD tools, Solid Edge includes sheet metal-specific features like emboss, dimple, drawn cutout, Hems can also strengthen a sheet metal part or play a functional role such as housing a pin for a hinge. Hems can be open, closed or teardrop-shaped. When adding a hem to a sheet metal part, a few guidelines should be followed to ensure optimum performance. For starters, it is almost always better to avoid closed hems — those in which the . Sheet metal strengthening techniques enhance durability in stamped parts for industries like automotive, construction, and defense. Learn more.

Set the project file for exercises; Exercise 1 Configuration of styles and template for sheet metal parts; Exercise 2 Drawing template modification. Sheet thickness in title block; Basic techniques for creating sheet metal parts. Exercise 3 Flanges and mirror copy. Sheet metal wheel support; Exercise 4 Flanges and corners. Sheet metal boxInsert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude, etc.), and then insert bends or convert to sheet metal. However, these options are problematic In the present investigation, an integration of notch wavy rolling and cold rolling techniques was employed for strengthening of austenitic stainless steel sheets [5]. The processes and their parameters were optimized by evaluating the tensile properties of material thus processed. . The sheet metal appears to deform easily by formation of .

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download!Oct 25, 2024 - Explore Mahtabalam Khan's board "SolidWorks Sheet metal" on Pinterest. See more ideas about solidworks, sheet metal, sheet. Pinterest. Today. Watch. Shop. Explore. . Isometric Drawing Exercises. . SolidWorks Sheet . The primary purpose of sheet metal hemming is to enhance the metal sheet’s structural strength and durability. It makes the sheet metal stronger and more resistant to defects such as cracks, wrapping, and bending. Folding . Integrating hardware into the sheet metal is also key to connect and bolster the parts. Keep in mind that the hardness of the hardware should be equal to or greater than that of sheet metal materials. Available sheet metal .

how to strengthen sheet metal parts

Join this channel to get access to perks:https://www.youtube.com/channel/UCjd_zIvYtQymk0dPx3vTJcA/joinFOR DRAWING CHECK FACEBOOK PAGEFacebook page : https://.Help strengthen sheet metal part I have this sheet metal part (1.2mm ss304) that is cracking due to fatigue at the joint shown in pic. Is there any way I can strengthen this area and keep the flanges where they are? . A forum oriented towards trades-oriented painting & finishing techniques, products and support. We welcome questions from the . Embossing technique allows strengthening properties of sheet metal materials to be specifically increased. This increase in strength results from strain hardening and residual stresses, which are .ALL posts related to SOLIDWORKS are welcome. Share what you know. Learn what you don't. 100% Pirate Free Sub. Zero Tolerance

1. The document provides instructions for creating sheet metal brackets and parts using Solidworks. 2. Exercise 1 involves using base flanges, cuts, and chamfers to create a sheet metal bracket based on given dimensions and design intent. 3. Exercise 2 uses flange features to create another part, demonstrating skills like base flanges, sheet metal parameters, edge flanges, . The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. As illustrated in the accompanying figure, if the bending height is too low, the sheet metal is prone to deformation and twisting during the bending process , leading to suboptimal part shape and .

Fusion 360 sheet metal exercise for beginners | 3D modeling exercise 09 | Complete Step by Step Sheet metal tutorial.Download fusion 360 sheet metal tutorial.

Sheet Metal Certification Sample Exam Question 1: Design this part in SolidWorks using Sheet Metal features Unit system: MMGS (millimeter, gram, second) Decimal places: 2 Part Origin: Arbitrary Part Material: Aluminum, 1060 Alloy Material Density: 0.0027 g/mm^3 Sheet Metal Thickness: 1.20 mm Inner Bend Radius: 1.00 mm The primary responsibility of a sheet metal technologist is to develop the most efficient process method while considering production efficiency and flexible coordination. Features of Sheet Metal Parts. Sheet metal parts possess unique characteristics such as being thin and easy to form into various shapes.Doing so creates the stiffening rib that can be used to strengthen the sheet metal. The shape of the form is the result of programs created in the punch press programming system. Beaded Emboss Embossing operations are commonly used in sheet metal and vary in purpose and function; one such function is to add strengthening .

how to make sheet metal better

how to improve sheet metal parts

how to improve sheet metal

how to do sheet metal

At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward.

sheet metal strengthening techniques|how to strengthen sheet metal parts