sheet metal stiffening rib design Any raw steel (Stainless, CRS, HRS) Aluminum Some deburring issues Plastic Check heat & flammability Cardstock Check heat & flammability Galvanized, Galvaneal See more Find great deals on eBay for 2 Box Metal Detectors. Shop with confidence.

0 · stiffening ribs in sheet metal design

1 · stiffening ribs catia v5

2 · edge bulging tolerance sheet metal

3 · catia stiffening rib

The Fisher TW-6 is an industry leading 2-box metal locator. Locate deeply buried .

stiffening ribs in sheet metal design

Any raw steel (Stainless, CRS, HRS) Aluminum Some deburring issues Plastic Check heat & flammability Cardstock Check heat & flammability Galvanized, Galvaneal See moreInvolve us during design stage to optimize cost and performance in component design. Engineering changes can be costly. While . See more

stiffening ribs catia v5

Copper Highly reflective Paper stock Unless treated with flame retardant Silver & other prec. Metals Highly Reflective Localized Hardening – Due to the intense heat associated with . See more

There are three kinds of cutoffs in blanking: straight/square, half round or partial radius and full radius. The square cutoff is the most economical. The full radius is not recommended as it leaves an unavoidable “feather edge” burr along the outside material edge. See more

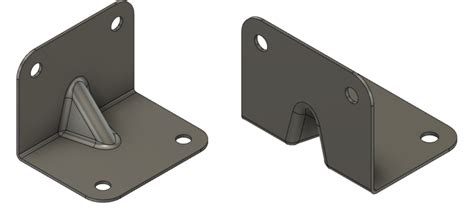

A common way to add strength to a sheet metal part is to add strengthening ribs. As the material is deformed, the effective material thickness increases, strengthening the material. Two ways .

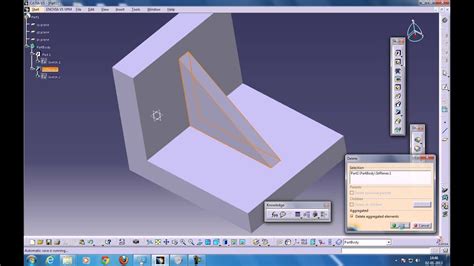

Catia Generative Sheetmetal Design - Stiffening Rib- How to create a stiffness rib on flangeCATIA V5 TUTORIALShttps://www.youtube.com/user/GOCATIA/playlistsC.

The sheet metal passes between the rollers, and the pressure shapes the desired bead profile. The bead roller uses a pair of complementary dies to roll a bead or rib into a sheet metal panel Shrinking and Stretching . Avoid the flat design . The flat sheet metal part is not strong enough, as it lacks of the structural integrity. In addition, the flat sheet metal part is easy to bend and deform under pressure. Therefore, the flat sheet metal .

Hi. I'm redisigning a sheet metal part that currently bends under load and needs to be stiffened. I'm considering applying ribsto the current design, but I do not know what is the better design for the rib itself or in which direction, lenght,etc. it should be placed on the part. I've been searching online but cant find much information about it.

edge bulging tolerance sheet metal

The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users. . or good it may purport to portray. This video shows how to use bend option and stiffening rib in catia sheet metal. like and subscribe to my channel PEACE Learn about the GrabCAD Platform .Download scientific diagram | Rib sizes (measures in millimetres, above) and ribbing process (below) from publication: Sheet metal plate design: A structured approach to product optimization in . The tool forms the sheet metal by “pinching” the material between two ball bearings in the upper assembly and one ball bearing in the lower assembly. Doing so creates the stiffening rib that can be used to strengthen the sheet metal. The shape of the form is the result of programs created in the punch press programming system. Learn the different techniques for strengthening sheet metal. 360-652-4200 REQUEST A QUOTE. 360-652-4200 REQUEST A QUOTE. . Without sufficient metal stiffening, components might deform, crack, or even shatter while in operation, endangering the final product’s performance and safety. . Avoid the flat design.

Catia - Generative Sheet Metal Design - (Stiffening Rib, Dowel, Check Overlapping, Views Management, Dxf.) | Catia | Generative Sheet metal #Design | #Manu. This will be the surface where the stiffening rib will be attached. Initiate the Stiffening Rib Command: Go to the "Generative Sheet Metal Design" panel and click on the "Stiffening Rib" icon. Select the Flange Surface: Select the flange surface where you want to place the stiffening rib. Specify the Length of the Rib: In the "Length L" field .Creating a Stiffening Rib Creating User-Defined Stamping Features Creating a Punch and a Die Opening and Cutting Faces Editing User-Defined Stamps . For the SheetMetal Design workbench, choose the Mechanical Design -> Sheet Metal Design item from the Start menu. For the Generative Sheetmetal Design workbench, .

Sheet metal design - Download as a PDF or view online for free. . The Stiffening Rib Definition dialog box opens, providing default values. 3. Change the value in the different fields, if need be: Radius R1, Radius R2, Angle A, Length L. 4. Click OK to validate. 73. The specification tree indicates the stiffness rib has been created.

Step 1: Generative SheetMetal Design. Gussets are triangular or L-shaped reinforcements that are typically added to sheet metal components to improve their strength and stiffness. In CATIA V5 Generative SheetMetal design, gussets can be created using a variety of methods, including: . Using the "Stiffening Rib" tool: This tool can be used to .

Doing so creates the stiffening rib that can be used to strengthen the sheet metal. The shape of the form is the result of programs created in the punch press programming system. Beaded Emboss. Embossing operations are commonly used in sheet metal and vary in purpose and function; one such function is to add strengthening ribs.The only exception is the feature called "Sheet Metal Gusset" but I doubt that is what you're looking for here. The reason most forming tools don't go across the bend region is due to the tooling required. Bending a flat surface is easy with standard tooling, but bending through a rib with standard tooling would flatten the rib in the bend region.This training course focuses on the Generative Sheet Metal Design workbench. Topics Covered in this CATIA V5 Training Course: Generative Sheet Metal Design workbench . bead, curve stamp, flanged cutout, louver, bridge, flanged hole, circular stamp, stiffening rib, dowel; Punch and die; Punch with opening faces; Sheet Metal features . 7. Start a new sheet metal part. Extrude a flat sheet with a thickness less than the minimum bend radius. 8. Open your design library tab on the right of your screen and navigate to your forming tools folder. 9. Click and drag your .

Cui et al. built a B-spline-based parameterization approach for curvilinear stiffening ribs and achieved a better design by optimizing the control point coordinates [22]; Alhajahmad et el. included the number of stiffeners, the stiffener profile and the stiffener orientations in their optimization framework, and showed that the curvilinearly .This learning guide focuses on the Generative Sheet Metal Design workbench. Topics Covered: Generative Sheet Metal Design workbench; . bead, curve stamp, flanged cutout, louver, bridge, flanged hole, circular stamp, stiffening rib, dowel; Punch and die; Punch with Opening Faces; Sheet Metal features – Corners, chamfers, cuts and holes .

We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal design guidelines for complex sheet metal parts. Therefore exceptions can be there for complex sheet metal parts. Live Stream — How I would create a rib forming tool with Sheet metal.Style: Casual Time: About 15-30 minutes (We all have other things to do :-)Fusion 360 fo.CATIA V5 Generative Sheet Metal Design Online Course acquaints the user with the various options of Sheet Metal Design operation and in turn the Sheet Metal parameters setting. . Create Stiffening Rib and Corner; Modify the feature; Stapler Magazine- 4. Create basic Sheet Metal features; Create Extrusion, Circular Pattern and Cylindrical Bend;Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. From consumer electronics, to medical devices, and obviously automotive - sheet metal part design plays a role in most modern products.

metal battery box

Search for jobs related to Sheet metal stiffening rib design or hire on the world's largest freelancing marketplace with 23m+ jobs. It's free to sign up and bid on jobs.

The stiffening rib in an outer metallic layer of a GLARE-based panel was fabricated by the incremental sheet forming technique and Alclad 2024-T3 aluminium alloy sheets were used as adherends. The strength properties of the adhesive joint between the layers of the fibre metal laminates (FMLs) were determined in a uniaxial tensile test, peel .higher volumes, pressing sheet metal is often more cost-efficient, due to the speed and ability to automate the majority of the process. The definitions of bending and pressing can be seen in chapter 3.2. The method of pressing sheet metal also enables more complex geometries and thus makes it possible to eliminate welding of the components.

Between rib to a bend perpendicular to the rib: ±2 times sheet thickness plus the radius of the rib plus the bend radius . Corner fillets are employed in sheet metal design to transform sharp edges into rounded ones, mitigating safety hazards and ensuring that the part is easily removed from the tool. These rounded edges not only enhance .

catia stiffening rib

Reduction of steel sheet thickness as a means of reducing vehicle weight may necessitate some method of enhancing flexural stiffness. Three basic types of sheet stiffening methods have been investigated: integrally formed rib stiffeners, foam-backed sheets and embossed material. Means of calculating the stiffness obtained by each method is .

During our investigation, I discovered an abandoned shipment from a Diplomat from London, UK and when scanned it revealed an undisclosed sum of money in a metal trunk box weighing .

sheet metal stiffening rib design|edge bulging tolerance sheet metal