setting electrical boxes for drywall Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists. A sheet metal fabricator installs and fabricates thin metal sheets. They typically work with a team to carry out tasks such as trimming, buffing, smoothing, and grinding metal surfaces. They also read blueprints and select gauges of metal for projects. They must be proficient with hand and power tools.

0 · old work electrical box install

1 · installing a remodel electrical box

2 · installing a new outlet box

3 · install outlet box without stud

4 · install old work ceiling box

5 · electrical outlet box installation

6 · electrical outlet box for drywall

7 · electrical box drywall no stud

Find a lower price on an exact item? We'll match it. Some exclusions apply. Return it in store or ship it back for free. Eligibility rules apply. Credit card, PayPal or Buy Now, Pay Later options available at checkout. Your choice.

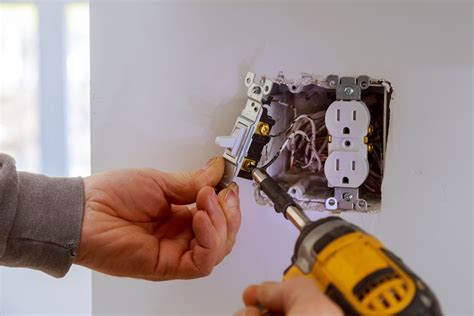

Installing electrical boxes the depth of drywall while studs and joists are exposed is a handy and simple solution for homeowners. To do this on your own, buy switch and receptacle boxes that meet local codes and are large enough for the wires they hold.Follow these expert tips to install an electrical box into drywall or plaster . Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists. Electrical box installation is regarded as easy work—more like carpentry than electrical wiring. But there are still some common errors that do-it-yourselfers frequently make. .

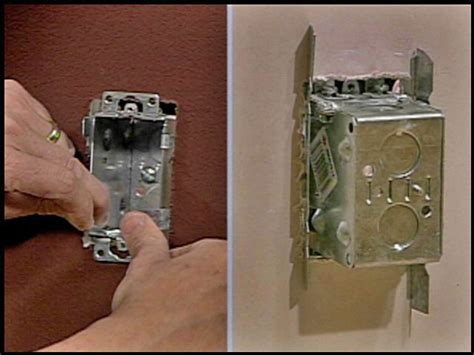

Cut-in electrical boxes secure into the drywall or plaster using wing screws or Madison straps, depending on the type of box you have. The wings press against the drywall . When placing the blue Carlon (non-adjustable) PVC outlet & switchboxes on 2x4 studs, they have alignment tabs that allow proper depth for 1/2" drywall. Several have been set .

Installing an electrical box at the proper depth of drywall involves several steps, including determining the location of the box, marking the outline on the drywall, cutting out the opening, measuring and cutting the hole in the . This is a quick tutorial that shows you how to mount an electrical box to be flush with drywall.How-To. Installing New Work Boxes. Follow these guidelines to attach boxes directly to exposed framing members. By Mike Litchfield, Michael McAlister. Once you’ve used your plans to locate receptacle, switch, and light-fixture boxes on . Making accurate electrical box cutouts boils down to a simple method that allows you to slice through drywall while leaving the box, and the wires within, undamaged. This .

I used drywall screws in the past for electrical boxes and stopped using them when I found that they snap off too easy when using a powered driver to insert the screws. They can also snap if there is any reason that the . Making accurate electrical box cutouts boils down to a simple method that allows you to slice through drywall while leaving the box, and the wires within, undamaged. This technique entails using a rotary tool with a multi-purpose cutting bit, like this ⅛-inch multi-material cutout bit from DeWalt — a power tool accessory every homeowner .Pull the box out of the wall and look inside to see what’s causing it to be crooked. Shave the stud, trim the drywall, shim, ect to fix the problem. You can reuse the old box or use a new one that has the angled holes for securing to the stud . I installed the boxes using the tabs on the side as a guide. I tacked up a section of sheetrock. The face of the box is below the surface about 1/4" I measured the tab on the box and it is only about 3/8" Add that to the round corner of the stud and it only sticks out 1/4 inch from the face of the stud.

Square Slot Cutter Drywall Oscillating Tool . Cut 2-3/8" x 3-3/4" or 3-3/4" x 4" holes on drywall quickly and accurately. Whether it's for installing outlets, electrical boxes, or any other hole-related tasks, it can meet your needs promptly.

old work electrical box install

installing a remodel electrical box

I would recommend toggle bolts for the receptacle box simply for their increased strength when pulling cords out. The corkscrew drywall anchors (commonly referred to as ez anchors where I live) are fine for supporting the emt but tend to pull out after repeated jostling, hence the toggles for the box. Or just try and land on a stud. Calculated Industries 8105 Blind Mark Drywall Electrical Box Locator Tool – Powerful Rare-Earth Magnetic Targets (3) and Locator Kit. . This 3-piece set from wolfcraft contains all tools that you need for clean and successful installation of hollow wall boxes in drywall. It contains a marking and alignment template, a carbon steel hole saw .

He would set a cut sheet of drywall up against the wall where it was to be hung, and look behind it to where electrical boxes were located. Then he would merely kick a hole in the sheetrock with his boots to get the cutout for the electrical boxes. I never had the pleasure of following him as a finisher.

Some of them even have a little spike so you can easily find your outlets when you’re hanging drywall. . Believe it or not electrical boxes is where a lot of air comes in through. Right soliton would have been to stay behind and around the box. . a really nice hairdryer with a 'cool' setting -look for about a 1500 watt model, minimum, and . Most plastic home improvement store electrical, single gang cut-in boxes seem to have little plastic tabs / bumps which if used, will set the box 3/8s inch off the studs. We are doing 1/2" drywall on the walls for sure (except on firewall of course). Most of the boxes are already nailed to the walls at the 3/8s" mark. One box (the outlets, for example) may need to move down to match the height of the other (the switches, for example) if there isn't enough room to move the switches up. Actually, I'd strongly recommend moving the outlet box, not the switch box, simply because there is less electrical work involved and, therefore, easier. –

With the electrical box hole cut in the framing, we can now proceed to step five: inserting the electrical box into the hole and securing it to the framing. When installing an electrical box at the depth of drywall in framing, make sure to use a box extender to bring the box flush with the finished wall surface. This will ensure a proper fit . This is a quick tutorial that shows you how to mount an electrical box to be flush with drywall. It is a very simple process, and you can have your electrica.Electrical boxes in double drywall? . would suggest that you use something like this box extender or you can go the difficult route and install deep retrofit boxes post drywall. . Use adjustable boxes that can have the depth set after the drywall is installed Reply reply

Set the drywall sheet in place against the wall. Stand the level on one of the pencil lines on the floor. . When working with electrical boxes and drywall, keep these safety tips in mind: Always turn off power to the circuit .Which brings me to using an old work box - probably out of your skill set because you have to redo all the wires. The laziest way is to get a reciprocating saw and trim the edges and be done with it. If the box is loose, you might be able to . Thanks for the advice everyone! Yes, I, just got boxes like these from my local electrical supply place. Actually I first got some tan Allied "Slider Boxes" from there, which I thought would work great because they are .

Using lipstick is the easiest way to mark where you can see where you need to cut your boxes out on sheet rock or drywall.Thank you very much for watching ou. in the cases where i used 5/8 drywall, my outlet boxes are a little too recessed, and unfortunately when i put the drywall in i already had the outlets (and the little wings that stick out slightly above and below the boxes) installed. so i just cut the drywall that extra 1/8" bigger than the box to accommodate the wings too. but now when the outlets are screwed all the way . drywall elctrical electrical boxes. . We used the notches on the box to set the boxes on the studs. If we tried to set them any further out, the nails would not even end up in a stud. After hanging drywall and rotozipping around the outside of the box, the boxes are mostly not flush with the drywall. Some worse than others, it's an old house. In this video I show you a few different ways how to cut out electrical boxes in drywall.How to Hang Drywall By Yourself - https://youtu.be/f_70XO2iY_UBathro.

Apply a coat of the mixed compound, forcing some through the tape into the gap, then allow to set ( I like to use the 20 minute set type). When set, drag the drywall knife across to remove any ridges and apply either another coat of the setting compound or use the premix mud. Sand when set (or dry) then prime and paint.

Anyone care to share experiences with mounting 1 or 2 gang boxes where double drywall and resilient channels are in place? In my neck of the woods adjustable Carlon boxes are harder to find than leprechauns. Found plastic Arlington box extenders however 1 1/4 is max extension. Suggestions or trade secrets? Trying to DIY a soundproof room.Press this against the box and then use drywall 3 or 4 screws to secure the 2x4 to the back side of the drywall. Then use one screw to hold the box to this 2x4. Or you could use the special metal clamps designed for this purpose to secure the box to the back side of the drywall. This prevents the box from moving out when a plug is removed. I understand the ease of cutting out around an electrical box with the sheet of drywall in place. No guess work, just locate the center of the box and then find the edges from there. . I suppose you could jsut ensure that you push all the cables in the boxes well and set the depth of the rotozip to just sllightly deeper that dw thickness. But .This way, when my second layer of 5/8" drywall goes up, it will be flush. I don't have enough depth with the boxes I am using to go out 1 1/4", so I am wondering if I can extend it 1 1/8" instead. This means the box will be recessed into the wall by 1/8" and I am wondering if that is okay. I don't want to install a box extender for just 1/8".

Arrow OSCGB1-1 1 Gang Electrical Box Drywall Cutting Blade for Oscillating Tools, Universal, Fits Most Multitools, Includes Adapter, Makes 2-7/8” by 3-3/4” Hole - Amazon.com . 5-Piece Set. .98 $ 22. 98. Get it as soon as Sunday, Sep 22. In Stock. Ships from and sold by Amazon.com. +

installing a new outlet box

covering old electrical boxes

CNC stands for Computer Numerical Control. This term can refer to a computer-based system that controls the motion of machine tools (machines) such as lathes and milling machines. In other words, it controls the machine tool’s ability to perform cutting or grinding operations.

setting electrical boxes for drywall|install outlet box without stud