what did they use before electrical junction boxes Sub-Panels. Homes built in the 1960s to 80s may be in need of a sub-panel these days—especially with the increase of appliances in homes and where garages or room additions are built. A sub-panel is a smaller . This guide will help you understand what is a junction box is and get the best possible junction box for yourself without any struggle when you need one. Follow the instructions, and you’ll soon find a reliable junction box!

0 · when did electrical boxes become a requirement

1 · What is / was the purpose of these old openable

2 · The Essential Guide to Junction Boxes: Types, Uses,

3 · So is my 1950s/60s era 2

4 · Old Electrical Wiring History

5 · Old Electrical Wiring FAQs

6 · Knob

7 · Common Wiring Issues in Old Homes: 1960s

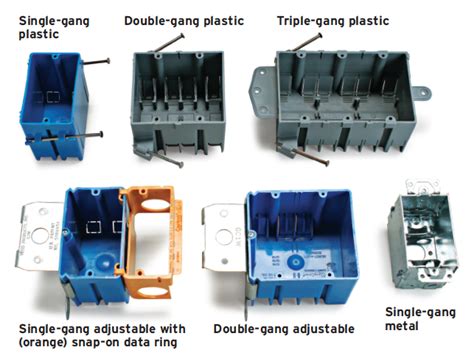

8 · 12 Types of Electrical Boxes and How to Choose

In a 4-axis CNC machine, the spindle travels along three axes: up and down, side to side, and back and forth, while the workpiece remains stationary on the machine table. The 4-axis CNC machining further rotates .

when did electrical boxes become a requirement

Q&A on the history of electrical wire & electrical wiring & on how to recognize knob and tube electrical wiring and unsafe "extension cord" wiring. In this article series we list .Given below, in order by patent date, are examples of early U.S. patents that help provide invention and first-use dates for types of electrical wiring and electrical wire conductor insulation and insulating sheathing. Sub-Panels. Homes built in the 1960s to 80s may be in need of a sub-panel these days—especially with the increase of appliances in homes and where garages or room additions are built. A sub-panel is a smaller .

Knob-and-tube wiring (sometimes abbreviated K&T) is an early standardized method of electrical wiring in buildings, in common use in North America from about 1880 to the 1930s. It consisted of single-insulated copper conductors run within wall or ceiling cavities, passing through joist and stud drill-holes via protective porcelain insulating tubes, and supported along their length on nail. A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers .

sheet metal chassis connection to automation

when did electrical boxes become a requirement. I don't know precisely, but I'd guess sometime around 1930's. That's when NM sheathed cable started replacing knob-and . Those analyzer readings to me suggest that the metal junction box holding the outlet is in fact grounded to the electrical panel somehow. The wires running to the electrical box are 1950s/60s non-metallic cable of the era, .

They appear to have been fuse boxes, which goes with the openable cover and diagram peeking out from under the paint. Presumably they were decommissioned as fuse boxes but retained as junction boxes. Learn about the importance of junction boxes in electrical systems, how they protect wire connections, and their role in commercial electrical setups. Written By: Steven Liang Last Update: September 5, 2024Got a call that their TV stopped working and some basement lights. After searching everywhere started to figure there was a buried junction box over a homeowner finished basement room. Didn't expect to find the box had pretty .

Most of the time fiber is used since it's a pain to properly ground UTP cable. If you couldn't do fiber, I'd have converted to coax for an outdoor run since that's easy to ground. Also if you note that box does NOT have a grounding screw like the .Earlier this week some cable guys installed a Verizon-branded junction box on each floor of the apartment, with pipes connecting them through each floor. Pictures: The junction box on my floor (without Verizon branding) The junction . A junction box is usually a plastic or metal box that contains the electrical wire connections. The wire connections should be completely enclosed inside these boxes. If you can see the wire nuts or electrical tape, then it’s a problem. The junction box cover may have been removed or was never installed to begin with. It's your choice whether to snake one run of cable or use junction boxes. But you need to have a junction box large enough to take the incoming power cable, a receptacle unit, and two or three branches continuing on. Also, if you use one of the receptacle boxes as a junction box, you need to be sure the box is big enough for the incoming cable .

My house is from the 1950s. The kitchen had 3 layers of linoleum flooring so I assumed it was remodeled at least 2 times before me. Looks like each time they spliced into an existing box to move the outlet or wall switch somewhere else and then just covered the old box. At least they put a cover plate on all of them and grounded them properly.

If e.g. a home gets hit by a high-voltage surge, it may be necessary to inspect all of the junction boxes for signs of damage. A prerequisite for doing that, however, is finding all of the junction boxes. A second issue relates to being able to list all of the loads served by each circuit and understand any requirements therefor. They work well together, and are designed for this. Octagon boxes are fine too but don't have many cubic inches. If you need big cubes, get 4-11/16 boxes like the 5-cable install above, but they are pricey at big-box stores for some reason. Don't bother with pricey boxes with flanges, they give metal boxes a bad name on price lol.411 box. (It is 4&11/16” square) Typically used as a junction box for more splices than a 1900 box (4” square) isn’t large enough for. They make mud rings and raised covers if you need to use it for a device or two. Why would I choose a large 4x4x2.5 metal box (this is what my brain tells me to use) vs plastic box. The plastic looks like they are all designed for installing switches or outlets and not covers but they are larger and cheaper. Is there a reason why one would not just use the plastic box and cover for a junction box either in an attic or basement.

Siding manufacturers make electrical junction box siding blocks that match the same style as color as the siding, good building contractors will install the proper one over my wire I stub out. Electrical supply houses can get generic exterior junction boxes, but they won't match the style or color of the existing siding, typically just white boxes. If the wires are installed in a junction box, then wire nut them separately, wrap some electrical tape around them, insert them back into the junction box and cover the box with an approved cover plate. If they are just dangling out of a hole in the drywall/tile, then you need to find out what junction box they come from, probably a switch box .I use flashing tape (like the kind used on your home wrap or around your windows) to seal the back and sides of a deep 4 square box (or 4 11/16" box for HDMI) and then install those on all exterior walls, including walls shared with the garage.

Equipment grounding wires outside of junction boxes. Thread starter marmathsen; Start date Mar 10, 2018; Status . Sometimes they used a crimp sleeve like in the photo, sometimes a wire nut. . A 1940's bracket box, without the tapped holes, and before galvanizing was the norm. The cable was always 2 wire, each cloth covered conductor .Unfortunately, the existing switch box serves as a junction box for lighting in another room, as well as some outlets. I've basically gotta leave that junction box there, or use a Tyco Splice kit. In my attic I've got gobs of room to put an exposed junction way up above the insulation. Why do electricians wire new builds this way?

What is / was the purpose of these old openable

The Essential Guide to Junction Boxes: Types, Uses,

While they’re here we’re also removing some of the older bx cables. In the basement there is an extremely complicated web of older bx cables that we just don’t understand. There’s a junction box every 2-3ft on every line and all are connected to each other like one large web. Is this something common that was done on purpose?

Once the boxes became non-conductive, the devices that REQUIRED grounding needed to have grounding screws. When I started as an electrician in the mid 70s, the code stated that for metallic boxes, you had to . I am trying to replace an outdoor light. The current light has a round mount and mounts over the round service junction box on the outside of the house. (The junction boxes are not recessed.) The new lights have a rectangular mount. When I mount them over the junction box, they stick out from the wall (not surpising) and don't sit squarely. Overcrowded Junction Boxes: Packing too many wires into a junction box can lead to overheating and poor ventilation, increasing the risk of electrical fires. Incorrect Wire Routing : Improper routing of wires can result in tension or strain on the connections, leading to loosening or damage over time. What is the smallest depth size for a 4"x4" wall recessed junction box in order to fit an 1-1/4" conduit on it? How about the depth for an 1-1/2" conduit? It's just to run AV and data cables in it, no wiring devices installed in the j-box just cables passing through.

the second major differentiator between plastic and metal boxes as far as switches and Outlets are concerned is that plastic boxes have a 2 inch by 4 in footprint, which quite frankly is a little bit easier to work with for tucking the wires in whereas gangable metal wall case boxes are 2x3 footprint and you have to compensate with more depth .Not all plastic boxes are old work, old work boxes have a different attachment mechanism so that you can simply cut a hole in drywall and secure the box, whereas new work boxes are nailed directly to the stud, which you can't do when the drywall is in place. Metal boxes are used when the wire is being run through EMT, metal conduit.

Now that you know, how a junction box is defined; let us talk about what it is used for. The Power of an Electrical Junction Box. A junction box acts as the summit, where the electrical wires connect before continuing their path. These boxes have different colors of wires portraying different elements. Originally I was planning to use an old-work electrical box. However, because of the thickness of the wall, I realized the flaps could not engage. Then I tried using a shallow electrical box, but as I was not sure about whether I'll have enough space to put the receptacle in, I removed that. Finally, I took the flap out for the old-work .

I just came across this while looking for a Bosch 800 replacement plug. I hope you were able to use the plug and not the junction box. If you did use the box, please look into the junction boxes melting. Ours just did and it is insane how many I am finding that catch fire/melt. Just wanted to give you a heads up! Take care. About the junction box on the outside: I've seen the disconnect switch put in a box there and wondered how the box is attached. . I've seen a chase nipple before so don't know why I didn't think of it. That method would be good if there is no wall handy for a box for the switch, but I'm not sure it has an advantage otherwise. . I don't know .

In my area of the world, junction boxes are allowed provided they remain accessable. However, the code is silent on how heavy a wire can be spliced using a junction box. I get a bit nervous when the amperage gets up to 40 and the voltage is 240. In the short term, I am sure that it will work but time and corrosion can take a toll.

sheet metal chicago il

Determining whether to purchase a wooden breadbox or stainless steel breadbox is a personal preference, but consider other factors. Picking the breadbox that goes best with the kitchen design or how much bread you use can also determine which bread box you need.

what did they use before electrical junction boxes|12 Types of Electrical Boxes and How to Choose