how to close a junction box One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing . The rule of thumb is that for every thousandth of an inch material thickness you need 1 amp, so for 1mm you should need around 40 amps but the voltage of your machine and wire .

0 · wiring a junction box diagram

1 · terminal junction box wiring guide

2 · junction box wiring problems

3 · junction box wiring instructions

4 · electrical junction box instructions

5 · connecting wires in junction box

6 · 6 terminal junction box wiring

7 · 3 terminal junction box wiring

I am about to dive into a lowered street truck and i want to shave everything. Im am by no means a great welder but i do ok with thick steel. But holy crap i need some pointers on welding sheet metal. I have a 220 hobart mig welder with gas at my dads, but i bought a 110 welder that is strictly.

You simply need to convert the outlet into a junction box: Flip the circuit breaker off; Unscrew the hots, neutrals, and ground from the outlet and remove the outlet; Splice the hot, neutral, and ground from both sides (charge .Video talks about how to terminate power at a receptacle box if you no longer need the receptacleAmazon LinksSperry Non Contact Voltage Electrical Tester - h. One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing .

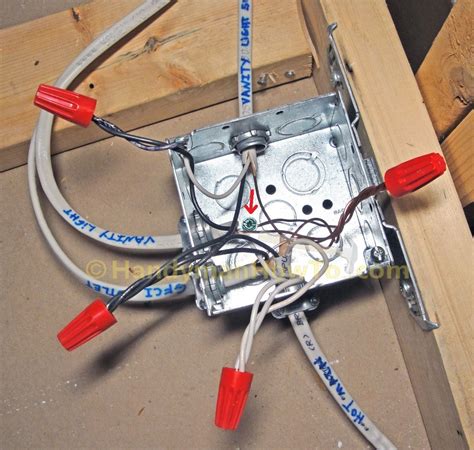

Step-by-Step Junction Box Installation Process. After you verify that the circuit is powered down, you can start installing your junction box. 1. Attach Box to Stud. If you’re installing an interior box, use screws or nails to attach . It's also a simple, approved solution for extending an electrical circuit since the National Electrical Code (NEC) dictates that no wiring splices are allowed outside an approved enclosure. Learn how to install an electrical . To wire a simple junction box, start by using wire strippers to remove approximately 3⁄4 inch (19 mm) of casing insulation from the end of each wire entering the box. .Steps for proper installation of a junction box. Installing a junction box is an important step in electrical wiring projects. It provides a safe and secure enclosure for electrical connections, helps to prevent electrical fires, and allows for easy .

Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also see our favorite tools to. This guide will help you understand what is a junction box is and get the best possible junction box for yourself without any struggle when you need one. Follow the . Somehow I wouldn't trust the 2x4 in the dirt. Is there a privacy fence/wall close to the hot tub? The flex can be extended from there. Save Share . Does it violate NEC if the four 6 awg THWN wires are spliced using block connectors, inside an outdoor junction box, with water tight fittings that connect it to the trenched PVC and to the . A simple guide to setting up an electrical junction box Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you'll need to strip the ends .

Secure the Box: Place the junction box over the mounting holes and fasten it securely using appropriate screws or fasteners, ensuring the box is level and flush with the surface. Connecting Wires Once the junction box is . That would put the boxes tight together. Plates for 4x4's are only a tiny bit bigger than the box itself, but they are bigger, so a chase nipple will not work. Use a close nipple or a shoulder nipple.

Thanks for those details, sorry you are experiencing this frustrating fuse box issue. Some Fords have fuse boxes that simply unplug but not this one, the wires going to it have no connectors right on the box. You can attempt to disassemble the fuse box to clamp the fuse and relay tabs back together or solder in new connections. Abandoned live wires under the sink is something we see far too often. It is improper, dangerous, and a shock hazard but luckily, a very easy deficiency to r. If I use a PVC J-Box, does one lock nut suffice to secure the nipple to the J-Box? Or what needs to be done? If I use a steel box I assume that it has to be bonded. Do two lock nuts on the J-Box suffice for grounding a steel box? The J-Box is being used to secure and route UF and SER cable - no splices. View attachment 2563780

Closing the Junction Box. Put the cover on the junction box. Secure the cover using screws or bolts. Wrap-Up: Mastering the Art of Drilling Junction Boxes. Drilling junction boxes may seem like a simple task, but it requires precision and attention to detail. By following the steps outlined in this guide, you can ensure that your junction boxes . Junction Box Size. Junction boxes are sized according to how many wires they can hold—because, among other things, an overstuffed junction box is a fire hazard. The National Electrical Code has published a chart that determines a junction box’s correct size, based on the number and size of the conductors it must accommodate. The size of a .Trimming the box doesn’t repair the issue of the box not sitting flush with the wall. Drive a straight blade screw driver into the stud side and manipulate the box. Run a drywall screw in the back of the box, 1 1/2 inch at the the longest. Why would you run a 3” screw through a 1.5” stud?

Those nails should not be inside the box, and replacing them will screws does not solve that problem. National Electrical Code 2014 Chapter 2 Wiring Methods Artical 314 Outlet, Device, Pull, and Junction Boxes; Conduit Bodies; Fittings; and Handhole Enclosures. III. Construction Specifications. 314.43 Nonmetallic Boxes.

To wire a junction box, first turn off the power to the circuit by switching off the appropriate circuit breaker. It is important to ensure there is no voltage present in the wires using a non-contact voltage tester. Choose the right junction box for the installation, considering factors such as the number of wiring connections and whether it .This central screw interfaces in some way with a bracket above the junction box. I can't tell if I'm supposed to turn the central post with a flathead screwdriver or turn the oddly shaped nut with pliers or something else.

Importance Of Safety And Power Shutdown. When it comes to extending electrical wire without using a junction box, safety should always be the top priority.Before attempting any electrical work, it is crucial to turn off the power to avoid any potential accidents or electrical shocks. This can be done by locating the breaker associated with the circuit and switching it off.

Then mount an octagon box to that. If you need a deeper box. Buy a box extension. Should be near the electric boxes. You can use plastic if you wish. Set your brace in the wall so your box sits flush or slightly behind the exterior sheathing. You will need to kill power to push the wires into the box as well as connect the fixture. 110.12 Mechanical Execution of Work. Electrical equipment shall be installed in a neat and workmanlike manner. (A) Unused Openings. Unused cable or raceway openings in boxes, raceways, auxiliary gutters, cabinets, cutout boxes, meter socket enclosures, equipment cases, or housings shall be effectively closed to afford protection substantially equivalent to .Replacing a Junction Box Cover. Your existing junction box should already meet the required National Electrical codes of standards, but if you happen to find one in your home that is missing a cover, it is best to have it replaced immediately. Because the splices where wires are connected together are housed in a junction box, they could end up .

junction box knockout dimensions

The goal here is to match wires.You do this by clicking on one of the wires from the left side of the box to whatever socket it matches in the middle, so if you see 1a on the left, look for .One box would require me running a new wire up to the first floor but even worse is the one that leads to my garage. The wire actually goes through the foundation wall that the junction box is attached to and under cemented ground to the garage, so there is no way to run a new longer wire to someplace I can put a junction box.The entire thing is a luminaire. The listed unit is secured to the ceiling with the spring clips. If you so choose to support a part of that luminaire to a stud or something, you need to make sure that the wiring is still accessible.

Hi everybody – I’ve got a question, and I hope somebody here can help me answer it. I’ve got a telephone junction box in my yard that’s falling apart, and I can’t figure out who to contact or how to get it fixed. When I say falling apart, I’m not kidding -- all . WISKA 207, 308, 607, 1010 & 1210If you use a junction box, it has clamps that put pressure on all the wires coming into it. That reduces the chances of the splice pulling apart. But, just in case it does, and the wires become exposed, the box is grounded.You cannot cover any junction box that still has live wires in it. Your best bet is to either remove the box all together or just put a cover plate on it. Your other option is to run a new circuit to the new box and de-energize the circuit to the old box and mark the source wires as "NOT IN USE" at your panel in which case I believe you could .

Putting a fan in and not sure this old box supports a fan. Was going to replace with new Dan certified but this thing won’t budge. No visible screws holding it in and the bolt in the middle appears to be welded to the box Any ideas how to remove this? Basically, junction boxes protect electrical connections from environmental conditions and accidental contact. Most lights that need to be hardwired int your electrical system will have a j-box. Whether you’re updating your entire set up or simply replacing an old, worn-out fixture, knowing how to properly install and replace a junction box . what has happened is that the outer jacket of the power cord has shrunk .. cut off the plug from the end of the power cord . strip away some of the outer jacket . firmly grab the wires with one hand and with your other hand push the outer jacket towards the fitting that you show in the picture . you have to keep stroking the power cord because the outer jacket will .

wiring a junction box diagram

terminal junction box wiring guide

When welding sheet metal, precise control and attention to detail are vital for successful welds. Understanding the distinct approaches of MIG and TIG welding is essential for working with materials like steel or aluminum, .

how to close a junction box|electrical junction box instructions