difference between bulk deformation and sheet metal process What is the difference between bulk deformation and sheet metalworking? In bulk deformation, the work parts have a low area-to-volume ratio, whereas in sheet metalworking, the area-to . The distributive property states that an expression of the form A(B + C) can be solved as A × (B + C) = AB + AC. Learn distributive property, types, examples & more!

0 · sheet metal forming process

1 · bulk metal deformation

2 · bulk forming vs sheet metal

3 · bulk flashcard deformation process

4 · bulk deformation vs sheet metal

5 · bulk deformation vs metal forming

6 · bulk deformation process in manufacturing

$19.00

Bulk deformation primarily deals with large volumes of metal, such as billets or ingots, while sheet metal forming focuses on thin sheets or coils. This distinction in starting materials leads to differences in the techniques employed and the types of products produced.

The main difference between bulk deformation and sheet metal forming lies in the area-to-volume ratio of the workpiece. In bulk deformation, the workpiece has a low area-to-volume ratio, while . What’s the difference between bulk deformation and sheet metal forming. The key difference between bulk deformation and sheet metal forming is that in sheet metal forming the .What is the difference between bulk deformation and sheet metalworking? In bulk deformation, the work parts have a low area-to-volume ratio, whereas in sheet metalworking, the area-to .

In sheet-bulk metal forming processes, the bulk deformation of sheet is carried out that invariably brings out the intended changes in the thickness as well. Some examples of bulk metal .Deformation processes can be conveniently classified into bulk-forming processes (e.g., rolling, extrusion, and forging) and sheet-forming processes (e.g., stretching, flanging, drawing, and contouring).This chapter provides an introduction to metal forming processes and where they fit among the five general areas of manufacturing. It also discusses the basic differences between bulk .What are the differences between bulk deformation processes and sheet metal processes. bulk deformation, the shape changes are significant, and the workparts have a low area to volume .

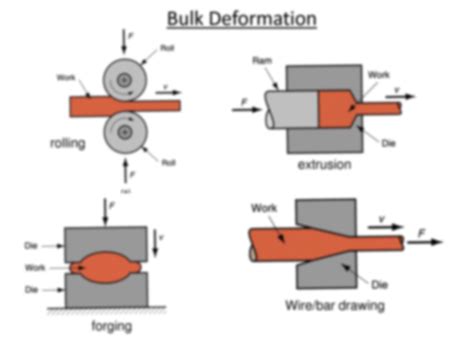

1. What are the differences between bulk deformation processes and sheet metal processes? 2. Extrusion is a fundamental shaping process. Describe it. 3. Why is the term pressworking .Four Basic Bulk Deformation Processes 1. Rolling –slab or plate is squeezed between opposing rolls 2. Forging –work is squeezed and shaped between between opposing dies 3. Extrusion .Bulk deformation primarily deals with large volumes of metal, such as billets or ingots, while sheet metal forming focuses on thin sheets or coils. This distinction in starting materials leads to differences in the techniques employed and the types of products produced.

The main difference between bulk deformation and sheet metal forming lies in the area-to-volume ratio of the workpiece. In bulk deformation, the workpiece has a low area-to-volume ratio, while in sheet metal forming, the area-to-volume ratio is high. What’s the difference between bulk deformation and sheet metal forming. The key difference between bulk deformation and sheet metal forming is that in sheet metal forming the deformation mode is predominantly tensile and the area-to-volume ratio is high.What is the difference between bulk deformation and sheet metalworking? In bulk deformation, the work parts have a low area-to-volume ratio, whereas in sheet metalworking, the area-to-volume ratio is high.In sheet-bulk metal forming processes, the bulk deformation of sheet is carried out that invariably brings out the intended changes in the thickness as well. Some examples of bulk metal forming are forging, rolling, extrusion, and wire drawing.

Deformation processes can be conveniently classified into bulk-forming processes (e.g., rolling, extrusion, and forging) and sheet-forming processes (e.g., stretching, flanging, drawing, and contouring).

This chapter provides an introduction to metal forming processes and where they fit among the five general areas of manufacturing. It also discusses the basic differences between bulk deformation and sheet-metal forming processes and how they relate to hybrid forming processes such as drawing, bending, and coining.What are the differences between bulk deformation processes and sheet metal processes. bulk deformation, the shape changes are significant, and the workparts have a low area to volume ratio. We have an expert-written solution to this problem! Describe the fundamental shaping process, extrusion.1. What are the differences between bulk deformation processes and sheet metal processes? 2. Extrusion is a fundamental shaping process. Describe it. 3. Why is the term pressworking often used for sheet metal processes? 4. What is the difference .

sheet metal forming process

Four Basic Bulk Deformation Processes 1. Rolling –slab or plate is squeezed between opposing rolls 2. Forging –work is squeezed and shaped between between opposing dies 3. Extrusion –work is squeezed through a die opening, thereby taking the shape of the opening 4. Wire and bar drawing –diameter of wire or bar isBulk deformation primarily deals with large volumes of metal, such as billets or ingots, while sheet metal forming focuses on thin sheets or coils. This distinction in starting materials leads to differences in the techniques employed and the types of products produced.

The main difference between bulk deformation and sheet metal forming lies in the area-to-volume ratio of the workpiece. In bulk deformation, the workpiece has a low area-to-volume ratio, while in sheet metal forming, the area-to-volume ratio is high.

What’s the difference between bulk deformation and sheet metal forming. The key difference between bulk deformation and sheet metal forming is that in sheet metal forming the deformation mode is predominantly tensile and the area-to-volume ratio is high.What is the difference between bulk deformation and sheet metalworking? In bulk deformation, the work parts have a low area-to-volume ratio, whereas in sheet metalworking, the area-to-volume ratio is high.In sheet-bulk metal forming processes, the bulk deformation of sheet is carried out that invariably brings out the intended changes in the thickness as well. Some examples of bulk metal forming are forging, rolling, extrusion, and wire drawing.

Deformation processes can be conveniently classified into bulk-forming processes (e.g., rolling, extrusion, and forging) and sheet-forming processes (e.g., stretching, flanging, drawing, and contouring).This chapter provides an introduction to metal forming processes and where they fit among the five general areas of manufacturing. It also discusses the basic differences between bulk deformation and sheet-metal forming processes and how they relate to hybrid forming processes such as drawing, bending, and coining.What are the differences between bulk deformation processes and sheet metal processes. bulk deformation, the shape changes are significant, and the workparts have a low area to volume ratio. We have an expert-written solution to this problem! Describe the fundamental shaping process, extrusion.

1. What are the differences between bulk deformation processes and sheet metal processes? 2. Extrusion is a fundamental shaping process. Describe it. 3. Why is the term pressworking often used for sheet metal processes? 4. What is the difference .

bulk metal deformation

lightning cnc plasma table parts

linksprite cnc parts

bulk forming vs sheet metal

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

difference between bulk deformation and sheet metal process|bulk deformation process in manufacturing