cnc machines what do they do The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how .

Buy Uxcell Junction Box Electrical Enclosure IP67 Waterproof ABS Plastic, Wall Brackets, Cable Glands 11.4 x 7.5 x 5.5 Inch at Walmart.com

0 · what is cnc machine definition

1 · what is cnc in manufacturing

2 · how to cnc machining work

3 · how cnc machine is controlled

4 · function of cnc machine

5 · cnc machine used for

6 · cnc machine meaning in english

7 · cnc machine acronym

Use industrial grade drill screws to mount the angle and your conduit and boxes. If you need more mounting space use some plywood between supports. I used this method to hang control panels for years. Buy the metal from a steel supplier, cheaper than strut and hardware.

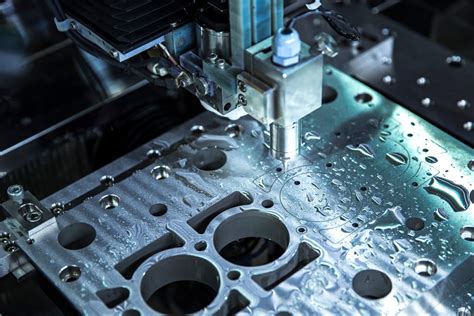

CNC machines utilize advanced technology, including computer programming and automation, to perform precise and accurate manufacturing processes. CNC machines follow a predefined process to remove material .

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or .Our guide covers everything you need to know about CNC machines, including uses, types, costs, and key buying considerations. Discover the ideal CNC machine for your needs. . They are .CNC Machining is a subtractive manufacturing technology, where material is removed from a solid block, or workpiece, using various CNC machining equipment such as milling machines, . Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC .

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how .

what is cnc machine definition

what is cnc in manufacturing

Essentially, it’s a technology that automates machine tools by using computers to control them. Instead of being manually operated by hand, CNC machines rely on a set of pre . CNC machining is a subtractive manufacturing process that uses computer-controlled machines to remove material from a solid workpiece to create a desired part. It encompasses a variety of techniques and machine .At its core, a CNC machine is a computer-controlled device that automates the operation of machine tools, such as mills, lathes, routers, and grinders. Unlike conventional manual machines, where operators physically manipulate tools, . A CNC machinist operates and manages computer numerical control (CNC) machines, using these precision machines to cut, shape and create parts and components from metal and plastic. They usually work from detailed .

What Files Do CNC Machines Use? A Comprehensive Guide. . The simplicity of STL files allows for easier integration with CNC machines, as they only require a closed mesh of interconnecting triangles. While STL files lack the intricate detailing available in DXF or DWG files, they prove highly effective when dealing with complex 3D shapes in .They create things out of plastics, metals, aluminum, wood and many other hard materials. The word “CNC” stands for Computer Numerical Control, but today everyone calls it CNC. So, how do you define a CNC machine? . CNC . They are either single or two-piece depending on the operator’s needs. . The MX is engineered for the CNC MASTERS machine so you do not have to fiddle with a detailed complicated configuration that can be overwhelming. Just load in the MX and start machining! Slide 1. 3. Features Tour and Tutorials Included

What is a CNC machinist? What does a CNC machinist do? These fundamental questions lie at the core of understanding one of the most crucial roles in modern manufacturing. In an era dominated by advanced technology and intricate engineering, CNC machining stands as a cornerstone. CNC machines drive efficiency and precision across industries. The .Conventional machine tools and computer numerical control (CNC) machines are both used for machining, but have significant differences in several key practical aspects.. So, if you are wondering whether CNC machines are better than traditional ones or whether it is time to replace your machines with automated solutions, below you will find all the elements you need for an .

how to cnc machining work

A CNC machine that operates on wood CNC machines typically use some kind of coolant, typically a water-miscible oil, to keep the tool and parts from getting hot. A CNC metal lathe with the door open.. In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such . CNC machines are used in a wide range of industries, including aerospace, automotive, medical, and consumer products. CNC machines can be used to perform a variety of tasks, including cutting, drilling, milling, routing, and engraving. CNC machines are capable of producing complex shapes and intricate designs with high precision and accuracy.

Understanding CNC Machines. CNC machines operate using computerized controls to automate and streamline the manufacturing process. They can work with various materials, including wood, metal, and plastic, to produce intricate designs with high precision. How Do CNC Machines Work? At their core, CNC machines follow a set of instructions provided . What is a CNC Machine? CNC stands for Computer Numerical Control. A CNC machine is a tool that is controlled by a computer. The computer tells the machine what to do. The machine can be anything from a router to a lathe to a mill to a plasma cutter. A CNC machine can be used to make things out of wood, aluminum, steel, or other materials. CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different types of CNC machines in industrial factories and the CNC Machine Shop, each with specific manufacturing purposes.However, all of them are used to craft the blank work material into the . What Files Do CNC Machines Use? A Comprehensive Guide. . The simplicity of STL files allows for easier integration with CNC machines, as they only require a closed mesh of interconnecting triangles. While STL files lack the intricate detailing available in DXF or DWG files, they prove highly effective when dealing with complex 3D shapes in .

1974 nova rear sheet metal

Precision Angular Contact Bearings - also known as Spindle Bearings - and are most often used in the main Spindle of CNC Machines and other Machine Tools. They can accommodate heavy axial loads at high speeds while maintaining running accuracy. All of which means that these bearings are ideally suited to applications in Spindles and CNC . According to our most recent Babcox Machine Shop Market Profile Survey, 12 percent of engine builders said they own a CNC machining center (a multi-purpose machine that can do surfacing, boring, milling, drilling, etc.).There is virtually no limit to what a CNC can do. CNC machines are responsible for almost all modern day machining operations in manufacturing industries. They normally costs tens of thousands of dollars, or hundreds of thousands of dollars. Our machines can be used to engrave plaques, cut wood for kits, mill aluminum parts, and inject plastic . What are the CNC machines and how do they work? CNC machine tools – in a nutshell – are the devices that allow the removal of excess material and shape parts due to the control of a specialized (computerized) controller. Such devices are sending commands to actuators and engines that execute the work, based on previously prepared CAM .

I have a chance to pick up these two comet CNC mills. They are in great shape and were in operation until the dude passed away in 2021. The wife just wants them out of there, I am either going to try and save em, or scrap em. They are 18-20k lbs, big ol 3 phase units. They powered on, but I know.In this blog post, we will explore the wide range of applications and capabilities of CNC machines, and understand why they are considered an indispensable tool in modern manufacturing. 1. CNC Machining: The Basics . Definition and working principle of CNC machines . Types of CNC machines (milling machines, lathes, routers, etc.)CNC technicians use computer software to create and modify the programs that control CNC machines. They may use a variety of software programs, including CAD (computer-aided design) and CAM (computer-aided manufacturing) software. CAD software is used to create 2D or 3D models of parts, while CAM software is used to generate the toolpaths and G .

It's important for machinists to learn new technologies and machines. They are proficient using a wide range of machinery equipment, including manual and computer numerical control (CNC) machinery. They understand specifics of machines, such as different machine feeds, speeds and cutting paths. Machinists also use a variety of measuring tools. What Does a CNC Machine Operator Do? A CNC operator is directly involved in the programming, set-up, and operation of CNC machines. On a daily basis, most CNC machine operators can be found doing the following tasks: . Supervise CNC machines as they run, making adjustments if needed; Ensure the machines operate in accordance with company and .

CNC files are digital blueprints that CNC machines use to carve, cut, or mold material. They contain specific instructions that guide the machine on how to produce a particular design. Why is the file format important in CNC machining? The file format determines the compatibility with different CNC machines and software. It is advantageous to use CNC machines in injection molding because they help create precise molds that are used for the production of plastic parts while facilitating multiple intricate cuts and patterns through the employment of tools like CNC laser cutters and plasma cutters, especially when it comes to sheet metal fabrication. Trainees often start with simpler machines like a CNC router or a lathe machine before progressing to more complex CNC lathes and 5-axis CNC systems. Practical experience allows individuals to understand the nuances of CNC machining operations, including CNC milling, CNC drilling, and CNC grinding. They use CNC programs developed for particular applications, mainly to control specific multi-axis machine tools like a milling machine, lathe, punch press, or a tube bending machine. Also, the CNC controller is normally a purpose-built controller that could be anything from a general purpose computer or a Programmable Logic Controller (PLC .

A CNC (computer numerically controlled) Programmer works with machinery which cuts raw materials into functional items. They are responsible for interpreting project blueprints, designing programs and setting up machines to produce the component outlined in the program. CNC, or computer numerical control, machining creates high volume precision turned parts and other parts for dozens of industries. CNC machining is ideal for companies looking for parts that are accurately designed and created using computers. Thanks to advancements of both the machines and computers, the process allows for intricate designs .

how cnc machine is controlled

Please call 800-799-4568, email, or chat for possible premium shipment options.

cnc machines what do they do|what is cnc in manufacturing