application of cnc machine tools Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. What are and Why use Junction boxes? Think of them as input and output connections, i will place a small storage box of the resource type in the middle of the extractor, and i will connect EVERY extractor of that resource type to that .

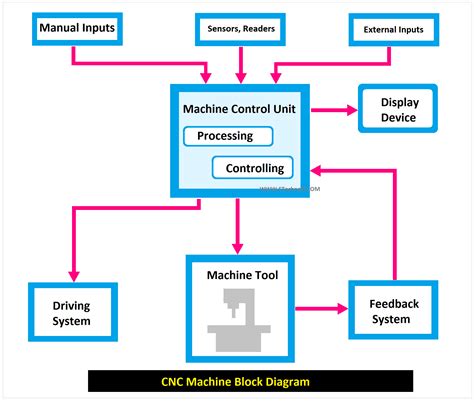

0 · schematic diagram of cnc machine

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

$15.99

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC stands for Computer Numerical Control. The CNC machining process is a manufacturing process that creates the final part by removing material using a cutting tool. There are many different types of CNC machines with numerous cutting tool options for a range of jobs and applications. Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

Some of the most common types of CNC machine tools include: Mills are equipped with precision routers, drills, and cutting tools that are programmed to remove material from a workpiece in a pre-determined course. They are capable of producing complex shapes and contours with high accuracy. In this blog, we will dive deep into different types of CNC machine tools and their specific applications in precision machining. By recognizing the various features and benefits of CNC equipment, manufacturers are able to choose suitable tools that can help them optimize production processes as well as enhance accuracy and reduce human errors.

CNC milling is a subtractive manufacturing process in which a computer-controlled rotating cutting tool selectively removes portions of a block of material to form a desired object. Milling technology existed as a manufacturing process before the incorporation of CNC . CNC Machining is a form of automated manufacturing that uses precision tools, either spinning cutters on a spindle (CNC mill) or a stationary tool against rotating raw material (CNC lathe), to create intricate parts. The spindle’s role is to provide the necessary rotational motion for precise material removal.

What Are the Usual Machine Tools Being Converted to CNC Applications? The common types of CNC machines include: CNC lathes: These machines are ideal for manufacturing symmetrical cylindrical or conical shapes, such as shafts, rods, and bushings. CNC milling machines: These machines cut and drill workpieces using rotary tools.

CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a vertical milling machine is perpendicular to the worktable. It is designed for machining small components, such as molds, fixtures, and precision parts. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC stands for Computer Numerical Control. The CNC machining process is a manufacturing process that creates the final part by removing material using a cutting tool. There are many different types of CNC machines with numerous cutting tool options for a range of jobs and applications.

Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to . Some of the most common types of CNC machine tools include: Mills are equipped with precision routers, drills, and cutting tools that are programmed to remove material from a workpiece in a pre-determined course. They are capable of producing complex shapes and contours with high accuracy. In this blog, we will dive deep into different types of CNC machine tools and their specific applications in precision machining. By recognizing the various features and benefits of CNC equipment, manufacturers are able to choose suitable tools that can help them optimize production processes as well as enhance accuracy and reduce human errors.

CNC milling is a subtractive manufacturing process in which a computer-controlled rotating cutting tool selectively removes portions of a block of material to form a desired object. Milling technology existed as a manufacturing process before the incorporation of CNC . CNC Machining is a form of automated manufacturing that uses precision tools, either spinning cutters on a spindle (CNC mill) or a stationary tool against rotating raw material (CNC lathe), to create intricate parts. The spindle’s role is to provide the necessary rotational motion for precise material removal. What Are the Usual Machine Tools Being Converted to CNC Applications? The common types of CNC machines include: CNC lathes: These machines are ideal for manufacturing symmetrical cylindrical or conical shapes, such as shafts, rods, and bushings. CNC milling machines: These machines cut and drill workpieces using rotary tools.

schematic diagram of cnc machine

2008 ford escape smart junction box

Alternating Currents is the follow-up quest to a Starfield side quest you can complete after meeting technician Louisa Reyez and helping her investigate some junction boxes in Tapping the Grid..

application of cnc machine tools|schematic diagram of cnc machine