cnc milling machine programming codes Learning G code programming is not that difficult. Read and learn about a G code. Understand how that G code work. Then make a simple G code . The way this is usually done is the ground wire is attached to a grounding screw on the junction box. The mounting bracket is then grounded by screwing it into the junction box. Then the braided wire connects to the green screw on the bracket.

0 · g m codes cnc list

1 · doosan mill g code list

2 · cnc turning g code list

3 · cnc n code list

4 · cnc milling machine codes

5 · cnc milling g code list

6 · cnc milling g code example

7 · cnc g code chart

You won’t get points on your licence for stopping in a yellow box junction, but the penalty charge can leave a nasty taste in your mouth if you feel it’s unfair. How and where can I.

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)N10 G90 (Setting Absolute mode); N20 G00 X1.0 Y1.0 (Position the machine at [P1]); .How to Apply G-codes relating to cutter compensation. Including Milling, .

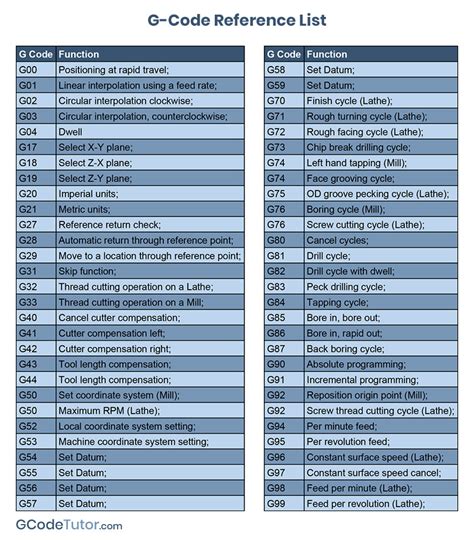

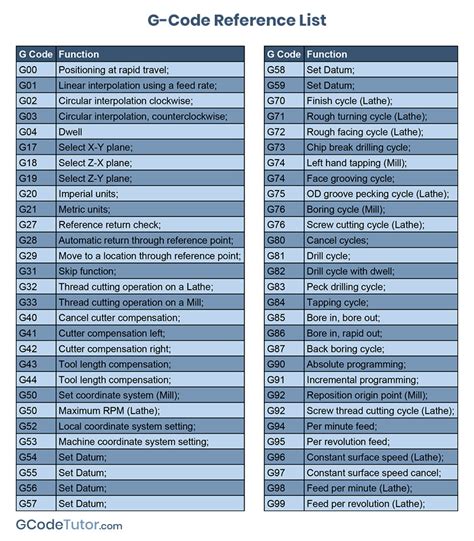

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands.

Learning G code programming is not that difficult. Read and learn about a G code. Understand how that G code work. Then make a simple G code . In CNC programming, M-codes are crucial for managing auxiliary functions that support the machine’s cutting operations. These commands allow operators to control .Here, we will dive into the fundamental concepts of CNC milling machine programming, such as machine axes, feed rates, spindle speed, and tool selection. You will learn how to set up the .

G-codes differ in different CNC machines, while M-codes are the same in most CNC machines. G-codes command the machine’s motion and function for the product’s design, while M-codes are used to conduct the non . Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections .Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin. G-codes, which control tool movement and cutting operations, form the backbone of CNC programming. Key G-codes include G00 (rapid positioning), G01 (linear interpolation), G02/G03 (circular interpolation), and G81-G89 .

CNC Mill Program Example. A very simple cnc milling machine programming tutorial for beginner level cnc machinists. An easy to understand cnc mill programming code. This is a cnc g code example without the use of any cnc .

g m codes cnc list

G-codes, which control tool movement and cutting operations, form the backbone of CNC programming. Key G-codes include G00 (rapid positioning), G01 (linear interpolation), G02/G03 (circular interpolation), and G81-G89 . Essential G-Code Commands. In CNC programming, essential G-codes streamline complex movements into straightforward instructions. For instance: G00 (Rapid Positioning): Moves the tool quickly to a specific point without cutting, ideal for fast repositioning. G01 (Linear Interpolation): Directs the tool to cut in a straight line at a set feed rate. G02/G03 (Circular .

cnc machining design guidelines

This is a basic program that makes a 0.100" (2.54 mm) deep cut with Tool 1 in a piece of material along a straight line path from X = 0.0, Y = 0.0 to X = - 4.0, Y = - 4.0. NOTE: A program block can contain more than one G-code, as long as those G-codes are from different groups. You cannot place two G-codes from the same group in a program block. I built my own DIY CNC machine from scratch, welding metals to make a rigid CNC body, and making CNC control systems for powerful motors. I gained unique experiences both building and working with that CNC machine, and I’ve also published brand-new research on how to cheaply cut granite and stone with a unique trick (check my guide for this).Holes Milling, Drilling. You will learn how to simulate machining and how to generate a machining program (G-Code) for a CNC milling machine. FreeCAD allows you to generate machining programs for GRBL (Candle), Mach3 and LinuxCNC. These are controllers often used in amateur, hobby and semi-professional CNC milling machines.

CNC Mill Program Example A very simple cnc milling machine programming tutorial for beginner level cnc machinists. An easy to understand cnc mill programming code. This is a cnc g code example without the use. 1.3 Theory of CNC Milling Machine 1.3.1 Characteristics of CNC Milling Machine Tools Work part machining on CNC machine tools requires controllable and adjustable infeed axes which are run by the servo motors independent of each other. CNC- milling machines (Figure 1.7) on the other hand have at least 3 controllable or adjustable feed axes .Cincinnati machining centers G-Codes & M-Codes of Acramatic 2100e cnc control. The following list of G & M codes applies to following Cincinnati ve

doosan mill g code list

A: G05 CNC code is applied to smoothen the movement of a CNC machine so that it produces parts with a finer finish. It does this by optimizing the interpolation thereby enhancing control of the machine tool as well as ensuring seamless shift between commands. Q: How can I use G05.1 Q1 in CNC programming? Learn about the G13 code for circular interpolation in CNC mill programming. Explore how to create circular pockets with the G13 command on Haas machines! Skip to . Helical profiles can accurately be produced in any machine controlled by G-code through helical interpolation within a G13 command if all the required parameters, such as start .

We will cover topics such as the concept of CNC, the role of programming in CNC milling machines, and the key components involved. Furthermore, we will explore the various programming languages commonly used in CNC milling machines, including G-code and M-code, and discuss their significance. Section 2: CNC Milling Machine Programming Techniques Once the machine is fed this G-code, it can then get a move on and make the part to the manufacturing standards mentioned within the code. Important Codes for CNC Programming. While “G-code” is the most commonly used term to describe CNC programming’s language, this can be broken down into several other types.

This lesson is part of a online course for CNC router owners available here:https://gcodetutor.com/cnc-router-programming.htmlThe best way to learn G-Code is.

CNC programming safety code and causes for crashes. How to avoid improper G-code NC programming mistakes. . End mill training education; Touch or tool probe systems; G10 parameter change; G codes, M codes List (General) . Here is an example safety code that is used on Fanuc controls. Machine tool builder and various machine models will . CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC .

A very simple cnc milling program example which shows how a simple slot can be machined. Sample cnc program for slot milling. . CNC milling sample program with program code explanation. This cnc milling machine programming tutorial . Popular CNC machines that work with CNC programming are CNC lathes and CNC milling machines. Since its inception, CNC programming has enabled people to make incredible carvings and many other things, from code. The CNC program make the machine tools and the CNC machines to interact with the work piece to create amazing things.

CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while monitoring for any issues.

cnc turning g code list

CNC milling machine controls like Fanuc, Haas etc, has ma. ≡ MENU. Home Fanuc Learn Examples Sinumerik Haas Reference Alarms Programming About. Fanuc Fanuc . G81 Drilling Canned Cycle CNC Milling Program Example Code. O10075 N1 T16 M06 N2 G90 G54 G00 X0.5 Y-0.5 N3 S1450 M03 N4 G43 H16 Z1. M08 N5 G81 G99 Z-0.375 R0.1 F9. Looking for CNC Programming, CNC Machine Programming, CNC G-Codes, or Examples in pdf form to download and study? As great as the world wide web is, sometimes it’s nice to have pdf’s that you can download, print, and hold in your hand. . New Tormach PCNC 1100 Mill Arrives at CNCCookbook. Titanium Machining How To [Tooling, Tips, and .

CNC programming is a critical skill for modern manufacturing, requiring a deep understanding of G-code, machine parameters, and toolpath strategies. To excel in CNC programming, focus on mastering the fundamentals of coordinate systems, tool .CNC Mill Program Example A very simple cnc milling machine programming tutorial for beginner level cnc machinists. An easy to understand cnc mill programming code. This is a cnc g code example without the use.

Deliverable: Hand Written G-Code Part Program. Drilldown on the link to see our Free Tutorial on Hand Writing G-Code Programs. One of the first things you’ll learn in the tutorial is how to run a CNC Machine like a Manual Machine. If you already know manual machining on a mill or lathe, you can be doing exactly the same kinds of things quickly on a CNC too.

I entered into the world of CNC Machining in 1991 as an apprentice for British Aerospace. After a four year apprenticeship I spent the following 26 years programming, operating and setting a full range of CNC Machines, including Lathes and milling machines. I specialise in programming FANUC and Heidenhain machine tool operating systems up to 12 .CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling, and drilling. CNC programming involves writing a series of commands, typically in the form of a . The production of precision parts goes beyond merely possessing a CNC machine; it requires a programming language that the machine can interpret—specifically, G-codes and M-codes. In 1952, to address the aviation industry’s need for accurate part machining, John T. Parsons partnered with IBM (International Business Machines) and MIT .

cnc machining engineers

cnc machining complex parts

Activate the Junction Boxes. With the Electric active, aim at the box and hit it to power it up, and let Officer Davis in.

cnc milling machine programming codes|cnc n code list