safe edge sheet metal How To: Tip an Edge on Sheetmetal with Hand Tools - Fabrication That Doesn't Suck. My KAR's Shop. 2.81K subscribers. Subscribed. 79. 4.9K views 3 years ago #HomeMadeTools #Fabrication . One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing valuable insights for DIY enthusiasts.

0 · tape for sharp metal edges

1 · sheet metal edge protector lowe's

2 · sheet metal edge finishing tool

3 · protective edge for sheet metal

4 · how to smooth metal edges

5 · how to protect sharp edges

6 · grinding edges of sheet metal

7 · edge moulding for sharp metal

These instructions contain important information on the installation and operation of the junction box. By following the given steps, haz-ards are avoided, repair costs and downtimes reduced, and reliability and service life increased. Read the mounting instructions carefully and attentively!

tape for sharp metal edges

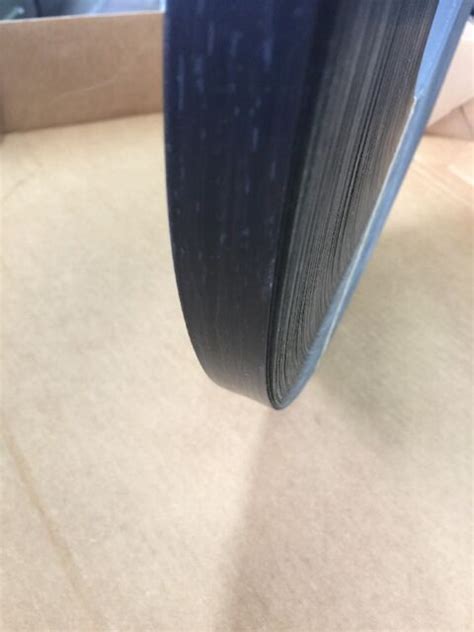

Step 1. – Secure the sheet metal to prevent slipping. Step 2. – Use a die grinder with the mounted point and simply run the point over the edge of the sheet metal. Step 3. – Repeat. Run the point over the other sides to .Choose from our selection of sheet metal edging, including rubber trim, plastic trim, and more. In stock and ready to ship. Edge protection serves as a barrier between sharp edges and those handling the metal. It prevents injuries and damage to the metal itself during handling, transportation, or storage. Additionally, edge protection can provide .

This video describes how you wire edge sheet metals for safety and durability. Sean Duke Bernadas BSECE 1-A TUPV Bongo by KV / kvmusicprod Creative Commons — Attribution 3.0 Unported — CC.

sheet metal edge protector lowe's

sheet metal edge finishing tool

How To: Tip an Edge on Sheetmetal with Hand Tools - Fabrication That Doesn't Suck. My KAR's Shop. 2.81K subscribers. Subscribed. 79. 4.9K views 3 years ago #HomeMadeTools #Fabrication .Flexible and stronger than tubing; often used to convey liquids and gases under pressure. 270 products. Choose from our selection of safety edges, including high-visibility corner guards, .Doubling a hem can create an edge perfectly safe to be handled without almost regard for the initial edge quality. Adding a hem in the ‘middle’ of a bend profile can open the doors to a variety of profiles not possible without fasteners or .

More machinable than copper and bronze for making nuts, hinges, and locks. Choose from our selection of sheet metal edge trim, including heavy duty plastic trim, rubber trim, and more. In .

10Ft White U-Channel EPDM Rubber Edge Trim, Fits for 1/16" (1.6mm) Edges, Self-Adhesive Edge Protector for Sheet Metal, Car Doors & Sharp Edges. 50+ bought in past month. 9. ..59.99

wholesale cnc milling parts processing

.93.89.99 The next stop on our tour of the sheet metal functions in Solid Edge is the Hem tool. Hem is just meant to fold over the edges of parts usually for safety, aesthetic, or strength issues.

dont put Jchannel at the edges of the metal roof. that will hold water, which in turn will allow the metal to start rusting at the one place it is most vulnerable, the edge, especially a cut edge. here's 2 ideas for the edge 1, . The manufacturer in this case took steps to prevent the sheet metal injuries but did not determine they were needed on this particular edge. While the sheet metal was very thin, making most standard deburring .

Rubber Edge Trim 1/16" U Channel Edge Trim Sheet Metal Edge Protector Flexible Self-Adhesive EPDM Rubber Edge Guard Protector for Panels, Car Doors, Steel Plates, Hatches, Table Corners(10Ft) 4.4 out of 5 stars. 9. .99 $ 7. 99. Save more with Subscribe & Save.Quiz yourself with questions and answers for Sheet Metal Safety Quiz, so you can be ready for test day. . Test: Sheet Metal Safety Quiz. Name: Score: 7 Multiple choice questions. Term. All sheet metal should be considered sharp on its edge. One should not run your hand along the length of the edge and hold material with a "C" type grip. True .Rubber Edge Trim, 1/16" Self Adhesive Flexible U Channel Edge Protecter for Sheet Metal, Car Doors, U Shaped Sharp Edge Protecter, Fit for 1-3/32" Width Edge, Black Color, 10Ft, EPDM Material 4.5 out of 5 stars 134

I have some sharp aluminum sheet metal, about as thin as a sheet of paper. I need to put something on the edge to protect other items from being cut by the edge. This could be a piece of rubber that fits over the edge, for instance. The nearest product I can find is the edging on sheet protectors. It has a "U" shape, so you can clip it over.

Its that tricky part of your apprenticeship sheet metal course, here slow and steady wins out.

Hemming is nothing but to fold the metal back on itself. In Sheet Metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. Hems are most often used to remove a sharp untreated edge and make it safe for handling.Curling sheet metal is the process of adding a hollow, circular roll to the edge of the sheet. The curled edge provides strength to the edge and makes it safe for handling. Curling is different than a tear drop hem because in a curl the edge finishes inside itself, where a .

Rubber Edge Trim U Channel, Self-Adhesive Edge Trim Sheet Metal Edge Protector, EPDM Rubber Edge Guard for Car Doors, Metal Plate, Glass, Table Corners, Hatches, Fit 1/16" Edge, 10 Ft Length 4.1 out of 5 starsChoose from our selection of edge protectors, including rubber trim, heavy duty plastic trim, and more. In stock and ready to ship. . Safety Supplies; Sawing & Cutting; Sealing; Shipping; Suspending (562) 692-5911. Email Us. . A lightweight alternative to metal and wood widely used in electrical and structural applications. 150 products .This short episode of Metal Magic provides some quick tips on the most effective ways to get sheetmetal to "lay down" properly. KITPLANES editor at large Pau.Kingdder Rubber Edge Trim U Channel Rubber Door Seal Strip Weather Resistance Sheet Metal Edge Protector Fits 1/8 Inch for Car Doors, Steel Plates, Glass, Hatches, Table Corners(10 Feet) 4.2 out of 5 stars. 264. 50+ bought in past month. .99 $ 8. 99 ( The three safe and stable screws are easy to adjust, and the height can be adjusted only by twisting, and the design of three numbers makes the sheet metal bender firmly fixed in place. . The sheet metal edge roller ..90 Even if the fabricator manages to punch the holes, part integrity will be less than ideal. To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate ..90 /Foot) Save more with Subscribe & Save.

Common Sheet Metal Shop Injuries and Hazards Sheet metal workers make use of heavy machinery to complete tasks. Devaes at the English Wikipedia, CC BY-SA 3.0, via Wikimedia Commons. Working with sheet metal .TRC House, Romsey Industrial Estate, Greatbridge Road, Romsey, Hampshire, SO51 0HR, United Kingdom +44(0) 1794 513 184. [email protected]. Registered in England & Wales Company Number: 08350831 VAT Number: GB 156 8355 80

Hems are often used when designers require a rounded edge on a sheet metal part. Approved Sheet Metal can fabricate parts with both open and closed hems. Hem return length should be a minimum of 4X the material thickness in length. . The purpose of a rolled hem is to eliminate raw sheet metal edges from a part, providing a clean and safe-to . Rubber Edge Trim, Self-Adhesive Rubber Edge Trim, Edge Protector for Sheet Metal, EPDM Material, Fit 1/16"(1.6mm), Length 10Ft, Black Color, U Channel Edge Trim 4.6 out of 5 stars 867 2 offers from 9 $ 5 99

SOKO Three-Station Edge Roller Bender, Sheet Metal Edge Roller Brake with 0-90° Bending Angle for 29 to 22-Gauge Steel, Adjustable for Making 5/8" to 4" (16 to 102 MM) Bends. 7.99 $ 187. 99. .00 off coupon applied Save .00 with coupon. FREE delivery Tue, Nov 19 . Or fastest delivery Sat, Nov 16 . This course takes you through designing parts in Solid Edge Ordered sheet metal mode.Features covered include:Creating tabsUsing the flange and contour flang.Hems are folds to the edge of a part to create a rounded, safe edge. Hems may be open, flat, or tear-dropped, and tolerances depend on the hem’s radius, material thickness, . Slot-to-edge distance SHEET METAL GUIDE V2.2 — TOLERANCES. Notches & Tabs DIMENSIONS The minimum thickness a notch must maintain is at least 0.04” (1mm) or the .Sheet metal hem is a fabrication process where the edge of sheet metal is folded over onto itself, creating a smooth, rounded finish that enhances the final product’s safety and aesthetic appeal. . Metal Siding and Roofing: Hemming creates durable and safe edges for metal siding and roofing, contributing to a structure’s durability and .

Introduction to Sheet Metal Edge Protectors. Sheet metal edge protectors are essential components designed to safeguard the edges of various materials, such as plywood and drywall. These slender yet robust materials serve multiple purposes, from providing a clean, finished appearance to preventing damage due to moisture and wear.

The sheet metal is then placed between the upper and lower pad and the punch is closed down transferring tonnage through the v die. . When a design calls for a safe, even edge the added cost of material and processing of a hem is often preferable to other edge treating processes.Covering sharp metal edges with a sharp edge cover. Sharp, metal edging is a major safety concern, especially when the edging is located where fingers, arms, and other limbs can reach it. Fortunately, all you need is some soft sharp edges protectors, sharp edge covers and a method to hold the edging in place to make the metal edging safe.

protective edge for sheet metal

Junction Box: A junction box is where the wires from the different switches and the light fixture connect. It often contains a neutral (white) wire and a ground wire (green or bare copper). Here's a step-by-step guide to wiring a 3-way switch: Turn Off the Power: Locate the circuit breaker controlling the light fixture and turn it off.

safe edge sheet metal|how to protect sharp edges