airsoft cnc milling machine This machine has desk of 1016 x 508mm, includes 4 axis and it is ready to go make some of your favourited airsoft parts. Thanks to that, our manufacturing capacity of RetroArms products can . What is a Junction Box? Vorlane defines junction boxes as enclosures for protecting and safeguarding electrical connections. They are also suitable for organizing big loops of wires in a place. A junction box also combines different cables when needed.

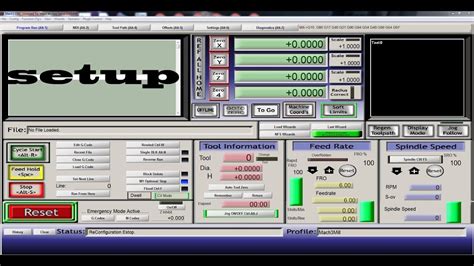

0 · newfangled solutions mach3 32 bit

1 · newfangled solutions mach3

2 · mill mach3 simulation mode

3 · mach3 cnc software

Electrical boxes encase wire connections to protect them from short circuits. They are vital for fire safety and are used for receptacles, ceiling fans, outside outlets, and more. Unless the device is one of the few that contains its own wires, it likely will need an electrical box.

Mach3 turns a typical computer into a CNC machine controller. It is very rich in features and provides a great value to those needing a CNC control package. Mach3 works on most .This machine has desk of 1016 x 508mm, includes 4 axis and it is ready to go make some of your favourited airsoft parts. Thanks to that, our manufacturing capacity of RetroArms products can .We've been been building and repairing Airsoft kit since 2007. From there we purchased a Lathe, and Milling machine to expand the possibilities. More recently we have moved away from .Ghost Gunner is a general purpose CNC mill that enables a growing library of gunsmithing applications. Engrave, customize, and finish 80 percent lowers to completion. 5x faster

Mach3 turns a typical computer into a CNC machine controller. It is very rich in features and provides a great value to those needing a CNC control package. Mach3 works on most Windows PC’s to control the motion of motors (stepper & servo) by processing G-Code.This machine has desk of 1016 x 508mm, includes 4 axis and it is ready to go make some of your favourited airsoft parts. Thanks to that, our manufacturing capacity of RetroArms products can expand of 30%, which leads to the faster procuts in stock in our internet store.

We've been been building and repairing Airsoft kit since 2007. From there we purchased a Lathe, and Milling machine to expand the possibilities. More recently we have moved away from doing just simple build and service jobs to more custom fabrication and . The closest thing to my experience milling a trigger is milling a pull trigger for a trip-wire grenade, and that took about 1 hour setting up and 2 hours to machine. You could go CNC. but that is a larger can of worms.

Whether you are looking for a CNC airsoft trigger, CNC airsoft gears, a CNC receiver, or any other CNC airsoft parts, our CNC design service can help you move an idea into reality. Contact us today to see how we can help you open up a . You don't simply just buy a CNC Mill or Lathe and hit a button and poof you have parts. Airsofter1999, I would enroll in some machining 101 classes and such first before you were to purchase any form of a CNC machine. Other things to consider that I would do if I had a CNC - Skeletonized outer barrel extensions - Outer barrels/barrel extensions with RS threading (1/2"x28tpi) for use with RS flash hiders

so my dad and i are planning on purchasing a CNC machine or Milling machine. that way, building custom guns will be a lot easier and more efficient. were trying to stay in the 3000 dollar range. He recently got his CNC machine working which can take 3D modeled stuff that can be made in programs like Solidworks. What cool stuff could I make on it, besides flash hiders? We're going to model a simple flash hider soon and test it.Ghost Gunner is a general purpose CNC mill that enables a growing library of gunsmithing applications. Engrave, customize, and finish 80 percent lowers to completion. 5x faster

Mach3 turns a typical computer into a CNC machine controller. It is very rich in features and provides a great value to those needing a CNC control package. Mach3 works on most Windows PC’s to control the motion of motors (stepper & servo) by processing G-Code.This machine has desk of 1016 x 508mm, includes 4 axis and it is ready to go make some of your favourited airsoft parts. Thanks to that, our manufacturing capacity of RetroArms products can expand of 30%, which leads to the faster procuts in stock in our internet store.

We've been been building and repairing Airsoft kit since 2007. From there we purchased a Lathe, and Milling machine to expand the possibilities. More recently we have moved away from doing just simple build and service jobs to more custom fabrication and .

The closest thing to my experience milling a trigger is milling a pull trigger for a trip-wire grenade, and that took about 1 hour setting up and 2 hours to machine. You could go CNC. but that is a larger can of worms. Whether you are looking for a CNC airsoft trigger, CNC airsoft gears, a CNC receiver, or any other CNC airsoft parts, our CNC design service can help you move an idea into reality. Contact us today to see how we can help you open up a . You don't simply just buy a CNC Mill or Lathe and hit a button and poof you have parts. Airsofter1999, I would enroll in some machining 101 classes and such first before you were to purchase any form of a CNC machine.

newfangled solutions mach3 32 bit

Other things to consider that I would do if I had a CNC - Skeletonized outer barrel extensions - Outer barrels/barrel extensions with RS threading (1/2"x28tpi) for use with RS flash hiders

so my dad and i are planning on purchasing a CNC machine or Milling machine. that way, building custom guns will be a lot easier and more efficient. were trying to stay in the 3000 dollar range.

newfangled solutions mach3

Sheet metal hemming is a type of sheet metal fabrication in which the thin sheet is bent and folded onto itself. The bent can have a closed shape, completely touching the metal surface, or be open with a slight cavity in between. The primary purpose of hemming is to add structural strength and durability.

airsoft cnc milling machine|mill mach3 simulation mode