cnc machine coolant brands Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid . Once the hole is cut in the wall for the box, feed the cable (or cables) out through .

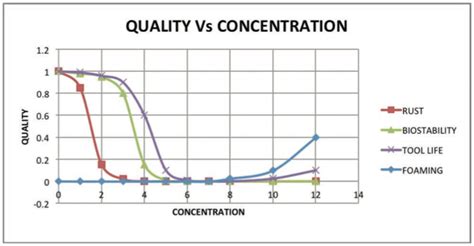

0 · machine coolant concentration chart

1 · coolant system in cnc machine

2 · coolant system for milling machine

3 · coolant concentration for cnc machines

4 · cnc machine coolant suppliers

5 · cnc machine coolant health problems

6 · cnc machine coolant disposal

7 · best coolant for cnc machines

There are many different metals that can be made into sheet metal, such as aluminium, brass, copper, steel, tin, nickel and titanium. For decorative uses, some important sheet metals include silver, gold, and platinum (platinum sheet metal is also utilized as a catalyst).

machine coolant concentration chart

Discover the best CNC coolant for your needs with our buyer's guide. Compare top products, learn proper usage, and optimize your .

coolant system in cnc machine

Choosing the right CNC coolant is vital for optimal machining performance and tool longevity. CNC coolant serves various purposes, including cooling the tools, lubricating the cutting process, and clearing away chips. Evaluate Coolant Options: Research different coolant types and brands. Compare properties, advantages, and disadvantages. Consider compatibility with the machining .

Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid . Learn how to choose the right coolant for your CNC machining needs. Discover the importance of selecting a coolant with anti-foaming properties, consulting with suppliers, and . FlexxCool’s automated system monitors your CNC machine’s concentration levels and keeps them consistent. Ensuring that you get the most out of your preferred coolant.

In this article, you will find information on various types of CNC coolants and how to choose the best one for your needs. There are several major categories of coolants used in .

Is there a guide out there to the various brands and types of water-based coolant mixes for milling? Tips on testing? They all suck, and everyone has an opinion about what is . Top CNC coolant brands include Benz, ICC, Master Chemical, Blaser Swisslube, and Milacron. Selecting the right CNC coolant is crucial for top machining performance. Coolants impact tool life, efficiency, and fluid consumption by reducing heat, friction, and debris.

coolant system for milling machine

coolant concentration for cnc machines

pvc junction box with divider

Typically, most CNC machine tools use one of the following types of coolant classified as follows: Soluble oils are the least expensive cutting fluids and the most common in machining operations. These so-called emulsions have excellent cooling and .

Discover the best CNC coolant for your needs with our buyer's guide. Compare top products, learn proper usage, and optimize your machining process!

Choosing the right CNC coolant is vital for optimal machining performance and tool longevity. CNC coolant serves various purposes, including cooling the tools, lubricating the cutting process, and clearing away chips. Evaluate Coolant Options: Research different coolant types and brands. Compare properties, advantages, and disadvantages. Consider compatibility with the machining environment. Seek Expert Advice: Consult coolant suppliers or technical experts for guidance. Request samples for testing and evaluation. Conduct Trials:

Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal. This article discusses how CNC coolant works, and its delivery technique. Learn how to choose the right coolant for your CNC machining needs. Discover the importance of selecting a coolant with anti-foaming properties, consulting with suppliers, and testing before full implementation for optimal machining performance.

FlexxCool’s automated system monitors your CNC machine’s concentration levels and keeps them consistent. Ensuring that you get the most out of your preferred coolant. In this article, you will find information on various types of CNC coolants and how to choose the best one for your needs. There are several major categories of coolants used in CNC applications: – Are compounds that comprise of mineral oil which has been emulsified with other ingredients to enable the preparation of an aqueous solution. Is there a guide out there to the various brands and types of water-based coolant mixes for milling? Tips on testing? They all suck, and everyone has an opinion about what is best, with no hard evidence to back it up. If you find a coolant that works, stick with it. Good semisynthetics are the closest thing to a universal coolant.

Top CNC coolant brands include Benz, ICC, Master Chemical, Blaser Swisslube, and Milacron. Selecting the right CNC coolant is crucial for top machining performance. Coolants impact tool life, efficiency, and fluid consumption by reducing heat, friction, and debris. Typically, most CNC machine tools use one of the following types of coolant classified as follows: Soluble oils are the least expensive cutting fluids and the most common in machining operations. These so-called emulsions have excellent cooling and . Discover the best CNC coolant for your needs with our buyer's guide. Compare top products, learn proper usage, and optimize your machining process!

Choosing the right CNC coolant is vital for optimal machining performance and tool longevity. CNC coolant serves various purposes, including cooling the tools, lubricating the cutting process, and clearing away chips. Evaluate Coolant Options: Research different coolant types and brands. Compare properties, advantages, and disadvantages. Consider compatibility with the machining environment. Seek Expert Advice: Consult coolant suppliers or technical experts for guidance. Request samples for testing and evaluation. Conduct Trials: Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal. This article discusses how CNC coolant works, and its delivery technique.

Learn how to choose the right coolant for your CNC machining needs. Discover the importance of selecting a coolant with anti-foaming properties, consulting with suppliers, and testing before full implementation for optimal machining performance.

FlexxCool’s automated system monitors your CNC machine’s concentration levels and keeps them consistent. Ensuring that you get the most out of your preferred coolant.

In this article, you will find information on various types of CNC coolants and how to choose the best one for your needs. There are several major categories of coolants used in CNC applications: – Are compounds that comprise of mineral oil which has been emulsified with other ingredients to enable the preparation of an aqueous solution.

cnc machine coolant suppliers

cnc machine coolant health problems

We have included a review of the function and basic types of metalworking fluids as well as a section on coolant main-tenance which defines the procedures needed for proper sump clean-out, machine charging and concentration control.

cnc machine coolant brands|cnc machine coolant disposal