class 1 div 2 electrical enclosures The National Electrical Code (NEC) provides comprehensive guidance on electrical requirements for Class 1 Division 2 (C1D2) locations. The guidance revolves around material groups, surface temperature and . The Metal Sheet is an Uncommon Crafting Supply in Unturned 3. Acquirement: [] Metal Sheets can spawn at the Belfast Airport, and other Construction Locations and hangars. Blueprints: [] Input: [] Metal Sheet (x2) + Metal Bar (x2) → Rifle Rack; Metal Sheet (x2) + Metal Bar (x2) → Placard; Metal Sheet (x3) → Metal Post (x2) Metal Sheet (x2 .

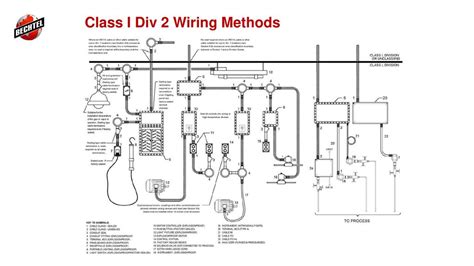

0 · class 1 div 2 wiring

1 · class 1 div 2 specifications

2 · class 1 div 2 rules

3 · class 1 div 2 receptacle

4 · class 1 div 2 nec

5 · class 1 div 2 enclosure requirements

6 · class 1 div 2 distances

7 · class 1 div 2 certification

UMF Medical’s 7780 Narcotic Locker is manufactured with 20-gauge steel, offering double doors, double locks and three shelves. Ships standard with separate Cam-style locks on each door, each keyed differently; 2 keys provided per lock; Three adjustable metal shelves; Heavy duty Piano style door hinge; 20 gauge steel cabinet construction

class 1 div 2 wiring

The National Electrical Code (NEC) provides comprehensive guidance on electrical requirements for Class 1 Division 2 (C1D2) locations. The guidance revolves around material groups, surface temperature and .EJB enclosures are globally certified for use in worldwide applications. They are listed for Class I, Division 1 and Class II, Division 1 hazardous areas, and they also have IECEx and ATEX .Rely on nVent HOFFMAN to protect your electrical controls in Division 1 or Zone 1 areas with flameproof and explosion proof enclosures. Our enclosures also improve the reliability of . For indoor use in Class II, Division 1, Groups E, F, and G hazardous locations according to NFPA 70, this is also referred to as dust-ignition proof. **NEMA 10. These .

metal enclosures jaycar

.40Type 1 Enclosures constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts and to provide a degree of protection of the equipment .Class II devices exclude dust from the enclosure’s interior. When properly installed, a Class II device will not permit arcs, sparks or heat to ignite dust (or a dust cloud) on or Class 1 Division 2 (C1D2) enclosures are designed to house electrical equipment in hazardous locations. These locations are areas where flammable gases, vapors, or dust may be present in the air in quantities .

Understanding the importance of Class 1 Div 2 classification is crucial for professionals in hazardous environments, ensuring the safe operation of electrical equipment. This understanding guides the selection of safe, .Ingress Protection (IP) codes for electrical enclosures in Class 1/DIV 2 and non-hazardous locations. An IP (Ingress Protection) rating is used mainly by buyers in Europe to specify the .

We recommend electrical enclosures meet or exceed a NEMA rating of Type 4 or Type 4X for use in a Class1 Div2 hazardous location when used with appropriate purge systems. The National Electrical Code (NEC) provides comprehensive guidance on electrical requirements for Class 1 Division 2 (C1D2) locations. The guidance revolves around material groups, surface temperature and protection techniques against any risks.EJB enclosures are globally certified for use in worldwide applications. They are listed for Class I, Division 1 and Class II, Division 1 hazardous areas, and they also have IECEx and ATEX certifications.Rely on nVent HOFFMAN to protect your electrical controls in Division 1 or Zone 1 areas with flameproof and explosion proof enclosures. Our enclosures also improve the reliability of panels in hazardous locations with purge and pressurization solutions.

For indoor use in Class II, Division 1, Groups E, F, and G hazardous locations according to NFPA 70, this is also referred to as dust-ignition proof. **NEMA 10. These enclosures are intended to meet the Mine Safety and Health Administration (MSHA), 30 CFR Part 18 (1978). NEMA 11. General-purpose.

Type 1 Enclosures constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts and to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt).

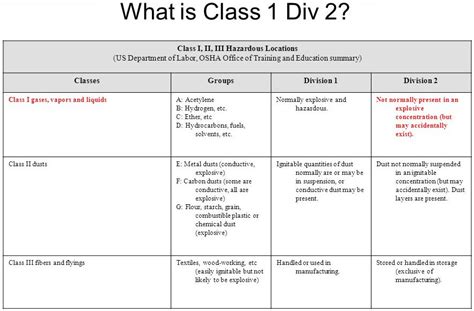

Class II devices exclude dust from the enclosure’s interior. When properly installed, a Class II device will not permit arcs, sparks or heat to ignite dust (or a dust cloud) on or Class 1 Division 2 (C1D2) enclosures are designed to house electrical equipment in hazardous locations. These locations are areas where flammable gases, vapors, or dust may be present in the air in quantities sufficient to produce explosive or ignitable mixtures. Understanding the importance of Class 1 Div 2 classification is crucial for professionals in hazardous environments, ensuring the safe operation of electrical equipment. This understanding guides the selection of safe, compliant devices for industries with elevated risks, like oil and gas or medical sectors.

class 1 div 2 specifications

Ingress Protection (IP) codes for electrical enclosures in Class 1/DIV 2 and non-hazardous locations. An IP (Ingress Protection) rating is used mainly by buyers in Europe to specify the extent of protection an electrical enclosure has against environmental conditions. We recommend electrical enclosures meet or exceed a NEMA rating of Type 4 or Type 4X for use in a Class1 Div2 hazardous location when used with appropriate purge systems.

The National Electrical Code (NEC) provides comprehensive guidance on electrical requirements for Class 1 Division 2 (C1D2) locations. The guidance revolves around material groups, surface temperature and protection techniques against any risks.EJB enclosures are globally certified for use in worldwide applications. They are listed for Class I, Division 1 and Class II, Division 1 hazardous areas, and they also have IECEx and ATEX certifications.Rely on nVent HOFFMAN to protect your electrical controls in Division 1 or Zone 1 areas with flameproof and explosion proof enclosures. Our enclosures also improve the reliability of panels in hazardous locations with purge and pressurization solutions. For indoor use in Class II, Division 1, Groups E, F, and G hazardous locations according to NFPA 70, this is also referred to as dust-ignition proof. **NEMA 10. These enclosures are intended to meet the Mine Safety and Health Administration (MSHA), 30 CFR Part 18 (1978). NEMA 11. General-purpose.

Type 1 Enclosures constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts and to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt).Class II devices exclude dust from the enclosure’s interior. When properly installed, a Class II device will not permit arcs, sparks or heat to ignite dust (or a dust cloud) on or

Class 1 Division 2 (C1D2) enclosures are designed to house electrical equipment in hazardous locations. These locations are areas where flammable gases, vapors, or dust may be present in the air in quantities sufficient to produce explosive or ignitable mixtures.

Understanding the importance of Class 1 Div 2 classification is crucial for professionals in hazardous environments, ensuring the safe operation of electrical equipment. This understanding guides the selection of safe, compliant devices for industries with elevated risks, like oil and gas or medical sectors.

class 1 div 2 rules

class 1 div 2 receptacle

How about turning the 0.5mm chamfer with the parting tool in 1:st operation? Then holding the part in a small drill chuck and finishing it up with a belt sander (or a file) and a steady hand. This is how i have done small parts in low quantities.

class 1 div 2 electrical enclosures|class 1 div 2 distances