cnc machine history John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s. So I essentially have a surface-mounted junction box underneath the sink. Is this a problem? The electrical box for the disposal outlet is meant for damp locations, and all wire .

0 · who invented cnc machine

1 · when were cnc machines invented

2 · when did cnc machining start

3 · history of cnc machine pdf

4 · evolution of cnc machines

5 · cnc timeline

6 · cnc machine history timeline

7 · cnc machine background

The under-the-cabinet SpaceMaker Toaster Oven is the perfect solution for baking a 9? pizza or toasting 4 slices of bread in compact kitchen spaces. Installation is simple with the included instructions, showing you step-by-step .

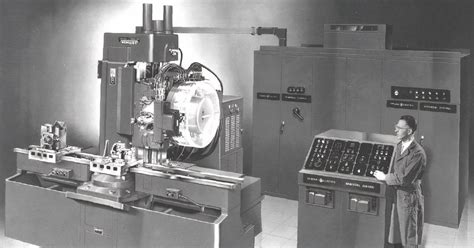

The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. The first NC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the controls to follow points fed into the system on punched tape. .

John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s.

The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to .CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots . In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as .

CNC machining’s history traces back to the urgent needs of the Second World War. The demand for complex and precise machinery parts, particularly in the aerospace industry, catalyzed the development of this .The foundation of CNC machines can be traced back to the mid-1940s when John T. Parsons and Frank L. Stulen developed the concept of numerical control. This early form of automation was . Computer Numerical Control (CNC) machining traces its roots back to the mid-20th century and has been revolutionizing the way machine components are crafted ever since – that is, with precision and efficiency. Learn how CNC machines evolved from early numerical control systems to modern computer-controlled systems that can produce three-dimensional parts. Discover the significance of CNC manufacturing and the .

who invented cnc machine

This section will introduce you to CNC machining history, the first CNC machine, and its evolution over time. The First CNC Machine The first CNC machine was credited to James Parsons in 1949.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s.

when were cnc machines invented

The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to automate machine tool operations using electronic controls.CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future.

In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as computer numerical control (CNC). CNC machining’s history traces back to the urgent needs of the Second World War. The demand for complex and precise machinery parts, particularly in the aerospace industry, catalyzed the development of this technology.

The foundation of CNC machines can be traced back to the mid-1940s when John T. Parsons and Frank L. Stulen developed the concept of numerical control. This early form of automation was introduced to improve efficiency and accuracy in creating complex parts for . Computer Numerical Control (CNC) machining traces its roots back to the mid-20th century and has been revolutionizing the way machine components are crafted ever since – that is, with precision and efficiency. A modern mainstay of manufacturing and production, computer numerical control, or CNC, goes back to the 1940s when the first Numerical Control, or NC, machines emerged. However, turning machines appeared before then.

This section will introduce you to CNC machining history, the first CNC machine, and its evolution over time. The First CNC Machine The first CNC machine was credited to James Parsons in 1949.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s.

The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to automate machine tool operations using electronic controls.CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future. In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as computer numerical control (CNC).

aluminum fabrication shop near me

CNC machining’s history traces back to the urgent needs of the Second World War. The demand for complex and precise machinery parts, particularly in the aerospace industry, catalyzed the development of this technology.

The foundation of CNC machines can be traced back to the mid-1940s when John T. Parsons and Frank L. Stulen developed the concept of numerical control. This early form of automation was introduced to improve efficiency and accuracy in creating complex parts for . Computer Numerical Control (CNC) machining traces its roots back to the mid-20th century and has been revolutionizing the way machine components are crafted ever since – that is, with precision and efficiency.

when did cnc machining start

Underfloor trunking (screeded) tested to withstand 30kN concentrated load. The system incorporates numerous design features to ensure a fast and simple installation. Designed to support CAT 6 structured cabling systems. Suitable for screeded depth from 56mm to 80mm. Floor boxes are IP30 rated in accordance with BS EN 60529.

cnc machine history|evolution of cnc machines