6 axis cnc machine working Among these, 6 axis CNC machines have emerged as game-changers, allowing manufacturers to achieve unparalleled precision and efficiency. This blog post delves into the world of 6 axis . Most precision turned parts products boast high quality and low MOQs with direct prices from factory, covering high precision turning parts, aluminum base with hard anodized surface .

0 · what is 6 axis machining

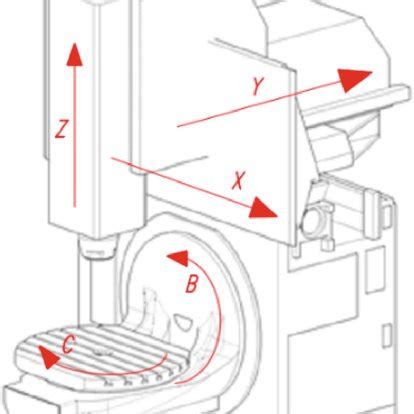

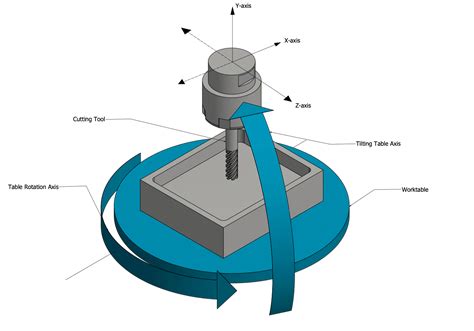

1 · haas 6 axis cnc

2 · cnc machine axis locations diagram

3 · cnc machine axis identification

4 · 6 axis milling machine

5 · 6 axis machining center

6 · 6 axis cnc milling machine

7 · 6 axis cnc machine price

wholesale cnc aluminum milling parts,SLD Precision offers top-quality CNC milling parts for various applications. With our advanced CNC milling capabilities, we deliver precise and complex designs in a wide range of materials.Get instant online quote for your metal or plastic CNC machined parts, from rapid prototyping to production. Tolerance down to 0.001 inches. Choose from 100+ materials, 60+ surface .

In this blog,we will focus on 6-axis CNC machines,uncovering their unique capabilities and the reasons why they are gaining popularity in various industries. A 6-axis CNC machine has six . This guide for 6-axis CNC machines will explain the concept of multiple-axis centers, outline their benefits and limitations and compare them to other automated machines. 1. What is a 6 Axis CNC?6-axis CNC machines combine cutting-edge technology with advanced milling capabilities to handle the most intricate designs effortlessly. From engine blocks to aerospace components, .

The emergence of 6-axis CNC machines has ushered in a new era of precision and versatility in the manufacturing industry. From improving accuracy in aerospace components to enabling .

Among these, 6 axis CNC machines have emerged as game-changers, allowing manufacturers to achieve unparalleled precision and efficiency. This blog post delves into the world of 6 axis .Turning centers often feature multiple axes (up to 5 or 6) and can perform complex machining tasks that would be impossible on a basic lathe. They also usually come with an enclosed .When we talk about a Six-Axis CNC machine, we're referring to the number of directions in which the cutting tool or machine can move. In a traditional Three-Axis setup, the machine moves along the X, Y, and Z axes—forward and .

In this guide, we take a look at the advanced 6 axis CNC machining process, explaining how it works, its benefits and what it's used for.In this blog,we will focus on 6-axis CNC machines,uncovering their unique capabilities and the reasons why they are gaining popularity in various industries. A 6-axis CNC machine has six degrees of freedom in its movement. This guide for 6-axis CNC machines will explain the concept of multiple-axis centers, outline their benefits and limitations and compare them to other automated machines. 1. What is a 6 Axis CNC?6-axis CNC machines combine cutting-edge technology with advanced milling capabilities to handle the most intricate designs effortlessly. From engine blocks to aerospace components, these machines ensure optimal performance and impeccable precision.

The emergence of 6-axis CNC machines has ushered in a new era of precision and versatility in the manufacturing industry. From improving accuracy in aerospace components to enabling the production of intricate medical devices, these machines have .

what is 6 axis machining

Among these, 6 axis CNC machines have emerged as game-changers, allowing manufacturers to achieve unparalleled precision and efficiency. This blog post delves into the world of 6 axis CNC machines, providing a comprehensive overview of their capabilities, applications, and impact on the manufacturing landscape. 1. Understanding 6 Axis CNC Machines:Turning centers often feature multiple axes (up to 5 or 6) and can perform complex machining tasks that would be impossible on a basic lathe. They also usually come with an enclosed setup to keep the workspace clean and safe. CNC lathes operate on the principle of .

electrical box plaster mud rings

When we talk about a Six-Axis CNC machine, we're referring to the number of directions in which the cutting tool or machine can move. In a traditional Three-Axis setup, the machine moves along the X, Y, and Z axes—forward and backwards, side-to-side, and up and down, respectively.CNC lathe machines are marvels of modern engineering, designed to perform CNC turning with incredible precision. But how do they work? At the heart of a CNC lathe machine is the concept of computer numerical control. This means the machine’s movements are directed by coded instructions, usually written in G-code.6-axis CNC machining takes complexity to a new level by adding a rotational axis. These machines are typically used for highly intricate parts requiring extreme precision. Suitable for parts with highly detailed features and tight tolerances, such as aerospace components or high-end consumer electronics.

In this guide, we take a look at the advanced 6 axis CNC machining process, explaining how it works, its benefits and what it's used for.In this blog,we will focus on 6-axis CNC machines,uncovering their unique capabilities and the reasons why they are gaining popularity in various industries. A 6-axis CNC machine has six degrees of freedom in its movement. This guide for 6-axis CNC machines will explain the concept of multiple-axis centers, outline their benefits and limitations and compare them to other automated machines. 1. What is a 6 Axis CNC?

haas 6 axis cnc

6-axis CNC machines combine cutting-edge technology with advanced milling capabilities to handle the most intricate designs effortlessly. From engine blocks to aerospace components, these machines ensure optimal performance and impeccable precision.The emergence of 6-axis CNC machines has ushered in a new era of precision and versatility in the manufacturing industry. From improving accuracy in aerospace components to enabling the production of intricate medical devices, these machines have .

Among these, 6 axis CNC machines have emerged as game-changers, allowing manufacturers to achieve unparalleled precision and efficiency. This blog post delves into the world of 6 axis CNC machines, providing a comprehensive overview of their capabilities, applications, and impact on the manufacturing landscape. 1. Understanding 6 Axis CNC Machines:Turning centers often feature multiple axes (up to 5 or 6) and can perform complex machining tasks that would be impossible on a basic lathe. They also usually come with an enclosed setup to keep the workspace clean and safe. CNC lathes operate on the principle of .

When we talk about a Six-Axis CNC machine, we're referring to the number of directions in which the cutting tool or machine can move. In a traditional Three-Axis setup, the machine moves along the X, Y, and Z axes—forward and backwards, side-to-side, and up and down, respectively.

CNC lathe machines are marvels of modern engineering, designed to perform CNC turning with incredible precision. But how do they work? At the heart of a CNC lathe machine is the concept of computer numerical control. This means the machine’s movements are directed by coded instructions, usually written in G-code.

cnc machine axis locations diagram

electrical box siding

electrical box punch out tool

Custom cutting availability for specialty. Explore the top of the line CNC diamond lathe cut machine at Wheel Repair World. Reface or refinish the surface of the wheel with highest precision and efficiency. Browse our CNC lathe cut machines now.

6 axis cnc machine working|6 axis cnc machine price