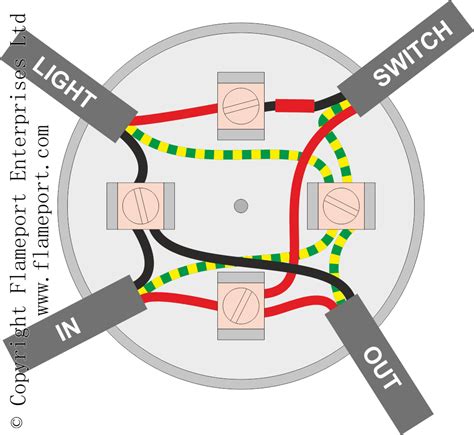

diy electrical junction box wiring To wire a simple junction box, start by using wire strippers to remove approximately 3⁄4 inch (19 mm) of casing insulation from the end of each wire entering the box. . For the floor supports I use 16 gauge. or the floor pans I use 18 gauge. Ford used 19 gauge on most exterior sheetmetal untill the mid 50's. Ford used 20 and 21 on non structural items.

0 · wiring junction box for lighting

1 · terminal junction box wiring guide

2 · junction box wiring problems

3 · junction box for electrical wiring

4 · how to mount junction box

5 · connecting wires in junction box

6 · 6 terminal junction box wiring

7 · 3 terminal junction box wiring

Cold and hot rolled steel: 16 gauge, 14 gauge, 1/8" and 1/4". Copper: 48 oz, 24 oz, 20 oz and 16 oz. Galvanized steel: 24 gauge, 20 gauge, 18 gauge and 16 gauge.

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing .How to wire an electrical junction box. A junction box is used to add a spur or to extend circuits and direct power to lights and additional sockets. Advice on wiring electrical junction box with .

Installing an electrical junction box gives you freedom and flexibility when installing electrical cables. It's often used when an electrical circuit branches off in two or more directions. To wire a simple junction box, start by using wire strippers to remove approximately 3⁄4 inch (19 mm) of casing insulation from the end of each wire entering the box. . Installing an electrical junction box is a handy skill for any homeowner to know. Check out this video where we walk you through how to install an electrical junction box step by step..In this ultimate guide, we will walk you through the step-by-step process of wiring an electrical junction box, complete with helpful diagrams to ensure a successful installation. First and foremost, it is crucial to understand the purpose and .

wiring junction box for lighting

An electrical junction box is a safety box used to cover wires that have been joined in a single electrical unit. An electrical junction box can either be made of metal or plastic. To save on costs, plastic junction boxes offer a . A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one. One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing valuable insights for DIY enthusiasts.

Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you’ll need to strip the ends off all the wires that will be in the box. To complete the electrical circuit, tie together the same-colored wires and hold them in place with wire nuts.How to wire an electrical junction box. A junction box is used to add a spur or to extend circuits and direct power to lights and additional sockets. Advice on wiring electrical junction box with easy to follow junction box wiring diagrams, including information on 20 and 30 amp junction boxes. Installing an electrical junction box gives you freedom and flexibility when installing electrical cables. It's often used when an electrical circuit branches off in two or more directions. To wire a simple junction box, start by using wire strippers to remove approximately 3⁄4 inch (19 mm) of casing insulation from the end of each wire entering the box. Once the wires are exposed, use a pair of pliers to twist .

Installing an electrical junction box is a handy skill for any homeowner to know. Check out this video where we walk you through how to install an electrical junction box step by step..In this ultimate guide, we will walk you through the step-by-step process of wiring an electrical junction box, complete with helpful diagrams to ensure a successful installation. First and foremost, it is crucial to understand the purpose and importance of an electrical junction box. An electrical junction box is a safety box used to cover wires that have been joined in a single electrical unit. An electrical junction box can either be made of metal or plastic. To save on costs, plastic junction boxes offer a cheaper alternative to metal.

Pull the wires you need to connect into the electrical junction boxes through the holes you’ve made. Allow six inches of wire to hang out of the box and then cut off any excess wire with your knife. You want ample wire so you can work easily, but not an excess. A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing valuable insights for DIY enthusiasts.

Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you’ll need to strip the ends off all the wires that will be in the box. To complete the electrical circuit, tie together the same-colored wires and hold them in place with wire nuts.How to wire an electrical junction box. A junction box is used to add a spur or to extend circuits and direct power to lights and additional sockets. Advice on wiring electrical junction box with easy to follow junction box wiring diagrams, including information on 20 and 30 amp junction boxes. Installing an electrical junction box gives you freedom and flexibility when installing electrical cables. It's often used when an electrical circuit branches off in two or more directions.

To wire a simple junction box, start by using wire strippers to remove approximately 3⁄4 inch (19 mm) of casing insulation from the end of each wire entering the box. Once the wires are exposed, use a pair of pliers to twist . Installing an electrical junction box is a handy skill for any homeowner to know. Check out this video where we walk you through how to install an electrical junction box step by step..In this ultimate guide, we will walk you through the step-by-step process of wiring an electrical junction box, complete with helpful diagrams to ensure a successful installation. First and foremost, it is crucial to understand the purpose and importance of an electrical junction box. An electrical junction box is a safety box used to cover wires that have been joined in a single electrical unit. An electrical junction box can either be made of metal or plastic. To save on costs, plastic junction boxes offer a cheaper alternative to metal.

terminal junction box wiring guide

junction box wiring problems

junction box for electrical wiring

1993 chevy silverado wire junction box engine compartment

Some metal-boring bits are recommended for drilling through hard metals but will damage thinner ones, so it's important to match the bit to the job. Light metals, including sheet metal: Choose a 135-degree flute bit made from any material but cobalt. A .

diy electrical junction box wiring|terminal junction box wiring guide