schematic model of sheet metal process The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed limitations, and life of tooling elements in the sheet metal .

Lexus LS 460 – fuse box diagram – passenger compartment fuse box no. 2 (passenger side)

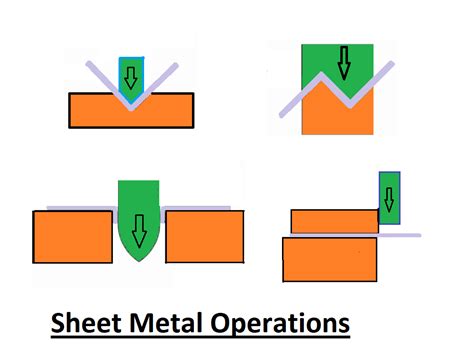

0 · types of sheet metal diagrams

1 · sheet metal operations pdf

2 · sheet metal operations diagram

3 · sheet metal fabrication process

4 · sheet metal fabrication pdf

5 · sheet metal design guide pdf

6 · sheet metal cutting diagram

7 · how to design sheet metal

An electrical socket back box, also known as an electrical box or wall box, is a device designed to house electrical outlets, switches, or other similar devices. Its primary purpose is to provide a protective enclosure for the .

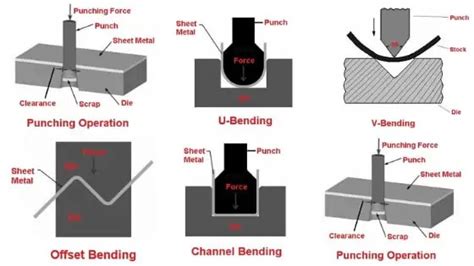

In sheet metal forming practice, we distinguish five basic modes of deformation: • STRETCHING: The material is expanded in both directions. This mode of deformation is found mostly on .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

SHEET METALWORKING. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Plate stock > 6 mm thick. Advantage. .The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In .

Modelling of Sheet Metal Process using Finite Element Analysis 2D-CAD Model to Find the Optimum Sheet Thickness. Vikas Srivastava, Amit Sahay*, Kamlesh Shivvedi. Dept. of . The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed limitations, and life of tooling elements in the sheet metal .The objects of this works will focus on simulating non-linear sheet forming process using finite element technique in order to come up with a clear and better understanding of metal flow of . Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including .

Download scientific diagram | Schematic of a sheet metal forming process from publication: Advances in the Control of Sheet Metal Forming | This paper presents a review of research on control of .

Download scientific diagram | Schematic illustration of the conventional sheet metal spinning process, adapted from [2] from publication: On the role of Anisotropy and Bauschinger-Effect in Sheet .

understanding of metal flow of sheet metal forming process. Schematic diagrams of shearing with punch and die are shown in Figure 1. 2. Bending Allowance and Spring-back Phenomena . Figure 6: Load and Boundary Conditions of Model 4.2. Punch, Sheet Metal and Die Bring Into Contact Before running the analysis, the punch, sheet metal and die are . Fig. 1 (a) shows the schematic view of the contact area between the sheet metal and the forming tool. As shown in Fig. 1 (b), the stress components on a small element in the contact zone are analyzed for the solution of the stress state in the contact area. The length of the small element can be expressed as dr and taken as 1% of the tool radius, which is about 0.05 .Download scientific diagram | Schematic representation of a stamping process. from publication: Development of process control in sheet metal forming | In sheet metal forming processes, the blank .a) With a schematic (diagram), explain the shearing mechanism in sheet metal forming (10 points) minimum 5 bullet points b) List two methods to achieve a burr free sheet metal ( 5 points [2.5 points each for the correct answeri) C) Why does barreling happen in open die forging ( 2.5 points) How can we reduce it? (2.5 points) d) Why are drawbead .

Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight Fig. 1.12 shows a schematic diagram of the process. The blank holder force (BHF) and clearance between punch and die should be carefully decided. Excessive BHF causes tearing, and too less BHF causes wrinkling. . Hol et al. [100] have presented a multiscale friction model for use in sheet metal forming. First, a microscale model predicts .The sheet metal stamping process is a strategic advantage that can set your business apart. Precision, efficiency, and innovation are at its core, driving the production of high-quality components. . This involves creating a 3D model of the dies that will shape and cut the metal. Precision in this step is vital to ensure accuracy and minimize .At work we use Inventor because of its integration with Vault for file management and better management of large assemblies, but at home, for making 1-5 part assemblies I prefer Fusion 360. The sheet metal design process is nearly identical on both. I would try to go with Fusion, it’s cheaper and has a larger and more up to date tutorial .

Figure 1 illustrates the schematic of the drawing process of multi-layer sheet metal t hrough a wedge- shaped die. The sheet has three layers Although the thickness and material type of the outer .Keywords: Simulation Modeling, Deep Drawing, FLD, magnesium alloy AZ31, M-K model 1. Introduction Most of sheet metal parts are manufactured via sheet metal forming. One of the most widely used sheet metal forming processes is the deep drawing involves a hydraulic or mechanical press in situ having a Therefore, the process model for sheet metal forming described by. Eq. . Fig. 3 Block diagram of the sheet metal forming model. Fig. 4 Schematic response of. F. p. to. F. b. with a step change.

Download scientific diagram | schematic for forming circular sheet metal into a cone. from publication: Physically-based modelling for sheet metal cone parts forming under blast loading | Forming .model representation of sheet metal parts in a sheet modeling system. 2. RELATED WORK Several CAD/CAM systems have been developed for modeling, process planning and manufacturing sheet metal products, including the systems proposed by de Vries et al [1], Shpitalni [2], and Inui et al [3]. Lee et al [4] describe the use of sheets for Bending is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. 7. Two common bending methods are: V-Bending Edge bending V-Bending: .

Download scientific diagram | (a) Scheme of the slitting process; (b) typical defects in the sheet sheared edge from publication: Application of variational and fem methods to the modelling and .Download scientific diagram | Schematic drawing of the electromagnetic sheet metal forming process [11] from publication: An application of high-power electromagnetic pulse: Forming of sheet metal .

types of sheet metal diagrams

sheet metal operations pdf

This work describes how an explicit finite element program can be applied to lay out industrial deep drawing processes, accomplished by the use of the FLD methodology and the updating procedure for the model data and the computational process. : New market requirements have becoming more persistent through the introduction of new technologies that can lead the .

Varying sheet metal properties due to batch fluctuations and changing process conditions lead to an increase of try out time phase and scrap rate, resulting in a demand for adaptive control . Even after the development of various non-conventional processes for sheet metal cutting, the shearing process remains the most preferred process in mass production.

sheet metal operations diagram

Download scientific diagram | Schematic representation of ISF process. from publication: Experimental and numerical studies on formability of extra-deep drawing steel in incremental sheet metal .

sheet metal fabrication process

An appropriate process model structure for the purpose of controller design for the sheet metal forming process is presented and parameter estimation for this model is accomplished using system . This paper presents a Finite Element (FE) model developed for the 3-D numerical simulation of sheet metal deep drawing process (Parametric Analysis) by using ABAQUS/EXPLICIT Finite Element Analysis (FEA) program with anisotropic material properties and simplified boundary conditions. The FE results are compared with experimental results for .In the deep drawing process, the friction between sheet metal and die can be reduced by ultrasonic vibration (UV) or low frequency vibration (LFV), and the forming performance can be improved by . the block diagram in Fig. 8. The process model is a ®rst-order nonlinear dynamic model. . A useful and easy-to-implement non-linear metal sheet deep drawing process model is provided by this .

Download scientific diagram | Schematic diagram of the conventional stamping process: a sheet preparation and dimension, b aluminum surface treatment, c aluminum skin and prepreg core assembly, d .

sheet metal fabrication pdf

With houses and other small, residential buildings, the phone company supplies wires from their pole or underground lines, and terminates them in a small junction box or demarc (as in demarcation, and pronounced "DEE-mark" by the guys whose pants hang too low) or network interface device or NID (pronounced "nid" by the aforementioned low .

schematic model of sheet metal process|how to design sheet metal