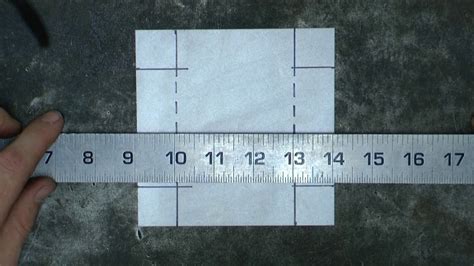

hot to make a sheet metal box How to Make a Sheet Metal Box: 1) first you want to make an expanded template for your box out of cardboard, paper, etc. ( a flat version of your box. I have a graph paper drawing in the pics below, but its not for this box) 2) trace your .

There are various types of corrugated metal roofing available in the market, including galvanized, aluminum, stainless steel, painted, and copper. Each type of corrugated metal roofing has its unique features, advantages, installation process, and maintenance requirements.

0 · sheet metal box layout

1 · sheet metal box fabrication

2 · sheet metal box drawing

3 · sheet metal box design guide

4 · sheet metal box design

5 · sheet metal blueprints

6 · metal box fabrication

7 · metal box design

Fab shops typically employ several welding methods, including spot welding, tack welding, fuse welding, stitch welding, plug welding, .

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my . How To Make a Sheet Metal Box - Shop Class Project. This is another great beginner sheet metal project I use in my shop classes. I use it to teach print reading skills and order.A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal .

box for shipping electric guitar

Challenging but Achievable: How to Make a Sheet Metal Box. Max Maker. 111K subscribers. Subscribed. 654. 18K views 3 years ago. __________________________ My Favourite Tools (Through. Creating a 22 gauge sheetmetal box from scratch. Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan brake .How to Make a Sheet Metal Box: 1) first you want to make an expanded template for your box out of cardboard, paper, etc. ( a flat version of your box. I have a graph paper drawing in the pics below, but its not for this box) 2) trace your .cut away ONLY the blackened area on the drawing. this will allow you to tuck the corners making the water tight seam. Step 3: Pre-Bending. using a screwdriver or wide, blunted chisel, slightly crease the corners. the 45 degree creases will be .

#sheetmetal Sheet Metal Design Sheet Metal FabricationSheet Metal Do you want to become an expert of Modeling on SolidWorks, then this video exactly for you..

__________________________My Favourite Tools (Through Amazon Influencer Shop): https://www.amazon.com/shop/depyrol__________________________Podcast:https://i. This is quick & simple tutorial for solidworks beginners starting working with sheet metal. DXF ready for metal fabricator shop!Follow simple steps to learn . This is a tutorial video on how to make a sheet metal tool box. It shows the Layout, Cutting, Forming and three different options for welding the box togethe.

If you are able to do normal four sided box folds then for the reverse flap you would have the option to make a normal box and then attach a separate plate to one side to create the riser flap. This could be attached with welding, spot welding, rivets or sheet metal screws. SOLIDWORKS Sheet Metal can be used in a variety of interesting ways. In this video, you will see how to use SOLIDWORKS Sheet Metal to create Corrugated or ca. Maker’s Mob Black Friday//Cyber Monday: https://go.themakersmob.com/black-friday-super-sale-neil/?via=neilSome of you wanted to see how I made the steel boxe. Fabricating a sheet metal box can seem daunting, but with the right tools and techniques, it can be a straightforward process. In this article, we’ll go over the steps to fabricate a sheet metal box, including cutting, bending, and welding. Step 1: Designing the Box. Before you start fabricating your sheet metal box, you’ll need to design it.

here i am making a 16 ga round steel box. this is a quick way to make a round cap shape fast start to finish this was 45 minutes to build. forming a round bo.

Hello everyone.In this video, I made a simple metal box for my tools. Having an organized storage makes my job easier and faster since l could not find my to.How to make a sheet metal box with simple tools, no brake press or bender.First, determine the dimensions and design of your sheet metal box. Sketch your design on paper, noting the length, width, and height, as well as any additional features such as mounting holes or cutouts. Be sure to account for the thickness of the sheet metal when calculating your measurements. Next, transfer your measurements onto the sheet .

#Solidworks sheetmetal boxIn this video i m going to show you, how to design & assemble an sheet metal box with inserts. Firstly we design a box, Firstly tak.

Creating a sheet metal box without tools might seem like a daunting task, but it's actually a fascinating and achievable DIY project. This guide will walk you through the process of crafting a functional and aesthetically pleasing the product using nothing but your hands and some clever techniques. Whether you're a DIY enthusiast, a crafting . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Another great Tech Eduard Khachaturyan joins us to show how to Fabricate a Metal Supply Plenum From Scratch. Here are some links to the tools in the process:.Welcome to our DIY Sheet Metal Box Tutorial! In this step-by-step guide, we will show you how to create a durable and functional sheet metal box, perfect for. This slide show shows how one can build a small metal foil box from discarded consumer container cans.How to Make a Sheet Metal Box: 1) first you want to make an expanded template for your box out of cardboard, paper, etc. ( a flat version of your box. I have a graph paper drawing in the pics below, but its not for this box) 2) trace your template on to your piece of sheet m.

to make: 1_decide what size box you wish to make. the box pictured is 6-1/4" w x 8-1/4"d x 3-1/2"h. then make a template. draw an outline of the desired size box on the large sheet of paper (I used a roll of craft paper from IKEA), leaving plenty of space around the perimeter to add the desired height of the sides. In this episode we build a metal brake for bending steel or aluminum. We need to make the aluminum battery box in the 1973 Datsun 240Z so this will help form. How steel sheet boxes are made: A skilled boy making perfect metal box without use of any electricity or welding, Making technique of a storage trunk with st. Unbalanced tooling (30/60) tilts the part being formed 15 degrees relative to the ram compared to a standard 45-degree tool set. This tilting allows a deeper box to be formed within the same tool height, measured from punch tip to ram bottom, as a 45-degree tool set (see Figure 2).. Unbalanced tools do introduce some risk of damage to the part or the tool from side thrust .

box fill canadian electrical code

How to Make a Metal Drawer!: In this Instructable, I will be showing you how to make a metal drawer for whatever you need. . Box of screws ; Something to cut the sheet and angle iron; Something to mount the drawer on! Optional: welder and angle grinder. Instead of drilling and tapping holes, you could also use Tek Screws or self tapping screws!A simple one piece tool tray is shown being fabricated from scrap metal. The process highlights the way dimensions of the box come to life by cutting the ap. Use the last marks to draw a straight line across the width of the sheet metal. Cut the sheet metal along this line. Insert the end of the cut piece of metal marked at 1 inch into the lock-former machine. Turn the machine on. Open the clamp mechanism of your sheet-metal break and insert the end of the metal with the lock-form.

sheet metal box layout

box electric company raleigh nc

sheet metal box fabrication

sheet metal box drawing

We find multiple types of junction boxes with their properties and advantages. For this reason, we categorize these electrical junction box types based on their features and applications. We will discuss each type in the following section to help you spot the best type for your requirements.

hot to make a sheet metal box|sheet metal box fabrication