cnc machine programming wiki The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the . Single gang two-piece snap together outlet box with adhesive backing. Box accepts Pan-Way Screw-On Faceplates or any NEMA standard .

0 · who invented the cnc machine

1 · when were cnc machines invented

2 · computer numerically controlled machines

3 · cnc machines wikipedia

4 · cnc machine meaning in english

5 · cnc machine history

6 · cnc machine basic knowledge

7 · cnc machine acronym

ODM precision aluminum 7075 cnc milling machined mounting parts. Material: Aluminum; Surface treatment: Sandblasted + anodizing; Note: Not all certifying agents offer online lookup, and .

G-code (also RS-274) is the most widely used computer numerical control (CNC) and 3D printing programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications. The G stands for geometry. G-code has many variants. G-code instructions are provided to a machine controller (industrial computer) that tells the motor.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the .

This manual is a beginners guide to writing macro programs for CNC. It explains the basic functionality of the macro programming language. I will assume you have some knowledge of . G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. You must be very familiar with the performance, characteristics and applications of CNC machine tools, cutting specifications and standard tool systems, otherwise you will not be .

The Milling Machine uses rotating tools (rod milling cutters, end mills, slot milling cutters, ball-end cutters, drills, taps, reamers, boring cutters, etc.) to process the plane, . The cnc lathe is one of the most widely used cnc machine tools today. This article explores the headings of step styles in CNC lathe parts processing. There are two kinds of cnc .

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] . It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers.G-code (also RS-274) is the most widely used computer numerical control (CNC) and 3D printing programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications. The G stands for geometry. G-code has many variants.

who invented the cnc machine

electrical box 2 gang to single

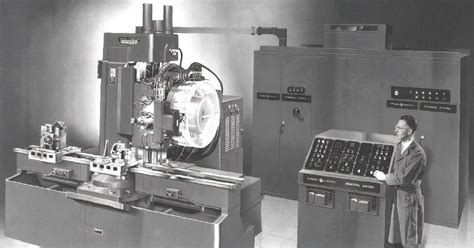

The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes , and 3D printers.

This manual is a beginners guide to writing macro programs for CNC. It explains the basic functionality of the macro programming language. I will assume you have some knowledge of G-Code programming already, as this is essential before learning the advanced programming techniques provided by the macro language. Section 1. What is macro programming G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. You must be very familiar with the performance, characteristics and applications of CNC machine tools, cutting specifications and standard tool systems, otherwise you will not be able to comprehensively and thoughtfully consider the whole process of part processing and determine the part processing program correctly and reasonably.

The Milling Machine uses rotating tools (rod milling cutters, end mills, slot milling cutters, ball-end cutters, drills, taps, reamers, boring cutters, etc.) to process the plane, internal control, internal and external contours, drilling, etc. of . The cnc lathe is one of the most widely used cnc machine tools today. This article explores the headings of step styles in CNC lathe parts processing. There are two kinds of cnc programming essentials: manual programming and automatic programming.

electrical box buried outdoors

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] . It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers.G-code (also RS-274) is the most widely used computer numerical control (CNC) and 3D printing programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications. The G stands for geometry. G-code has many variants.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.

CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes , and 3D printers.This manual is a beginners guide to writing macro programs for CNC. It explains the basic functionality of the macro programming language. I will assume you have some knowledge of G-Code programming already, as this is essential before learning the advanced programming techniques provided by the macro language. Section 1. What is macro programming

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. You must be very familiar with the performance, characteristics and applications of CNC machine tools, cutting specifications and standard tool systems, otherwise you will not be able to comprehensively and thoughtfully consider the whole process of part processing and determine the part processing program correctly and reasonably. The Milling Machine uses rotating tools (rod milling cutters, end mills, slot milling cutters, ball-end cutters, drills, taps, reamers, boring cutters, etc.) to process the plane, internal control, internal and external contours, drilling, etc. of .

The cnc lathe is one of the most widely used cnc machine tools today. This article explores the headings of step styles in CNC lathe parts processing. There are two kinds of cnc programming essentials: manual programming and automatic programming.

when were cnc machines invented

electrical box blank spaces cover

$275.00

cnc machine programming wiki|cnc machine acronym