business risk assessment cnc machine By the end of this guide, you will have a solid understanding of the necessary steps to ensure the safety of both operators and the surrounding workspace. Table of Contents: 1. Importance of . We're professional Aluminum Parts Cnc Milling Machining Parts manufacturers and suppliers in China, specialized in providing high quality customized products with competitive price. We warmly welcome you to wholesale bulk cheap Aluminum Parts Cnc .

0 · Understanding CNC Machine Risk Assessment: A

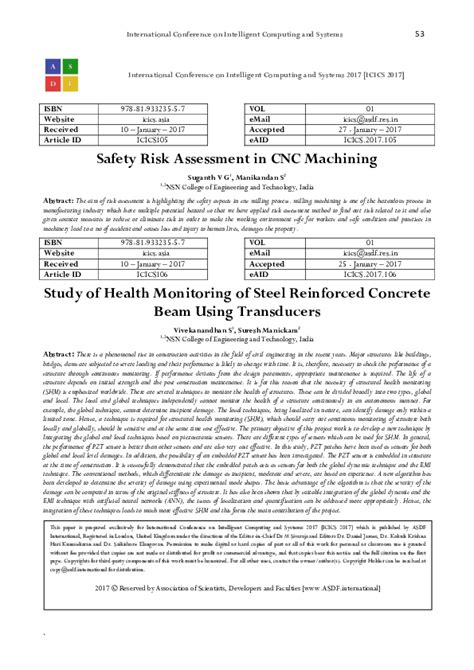

1 · Safety Risk Assessment in CNC Machining

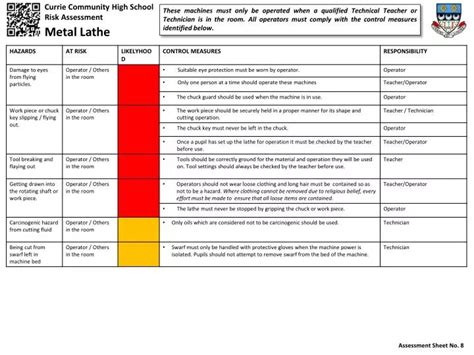

2 · Lathe Risk Assessment Template

3 · Lathe Machine Definition, Types, Hazards, and Control

4 · How to Perform a Safety Risk Assessment for

5 · How to Conduct an Effective Machine Safety Risk

6 · Ensuring Safety in CNC Machine Operations: A Comprehensive

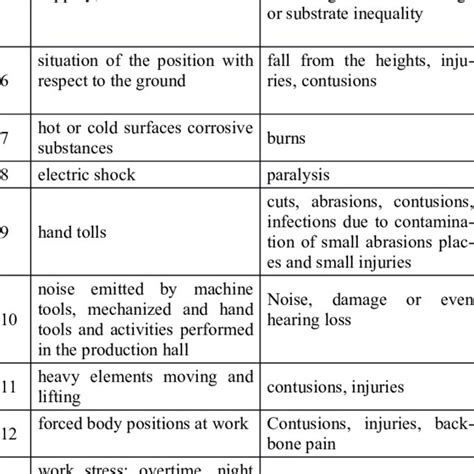

7 · Comparative occupational risk assessment in a CNC

8 · CNC Safety 101: Your Checklist for Secure Operations

9 · ANSI/ISO 12100:2012—Machine Safety Risk

10 · (PDF) Comparative occupational risk assessment in a

Get wholesale prices on electrical boxes, whether it's an outlet box, junction box, single gang or 2 gang, when you shop Elliott Electric Supply. From arrestors to electrical boxes and wiring devices, we've got your electrical needs covered.

Different CNC machines and tasks have unique risks associated with them. This section will discuss the importance of conducting job-specific risk assessments, including identifying .By the end of this guide, you will have a solid understanding of the necessary steps to ensure the safety of both operators and the surrounding workspace. Table of Contents: 1. Importance of .

A machine risk assessment identifies potential machine hazards, their severity, and how frequently people may be exposed to them. After conducting a machine risk assessment, strategies and machine-guarding .

electrical enclosure air conditioner sizing

Occupational risk assessment is a primary prevention and health task in every workplace. This assessment is mainly intended to ensure the safety of employees and to .Risk assessment tools such as risk matrices or risk scoring systems can be used to assign levels of risk to each hazard. In this section, we will provide an example risk assessment matrix . In order to design machines that are safe to operate and easier to keep within budget, the machine safety lifecycle helps manufacturing facilities identify safety hazards and mitigate risk to build safer machines before their . The paper presents the results of the occupational risk assessment carried out on the example of a CNC ma-chine operator by means three-stage methods in accordance with the PN-N-18001,.

Article highlights the importance of using methods of risk assessment as well as the importance of the security evaluation in manufacturing companies. This article provides an overview of the most widely used risk assessment methods and .

Understanding CNC Machine Risk Assessment: A

Here’s a five-step process to perform a safety risk assessment. Putting forth the effort in this stage will decrease the likelihood of problems arising in the future. 1. Get your team ready..The first step in establishing safety protocols is conducting a thorough risk assessment of the CNC operation area. Identify potential hazards such as sharp edges, moving parts, or .

Different CNC machines and tasks have unique risks associated with them. This section will discuss the importance of conducting job-specific risk assessments, including identifying hazards, evaluating risks, and implementing appropriate control measures.By the end of this guide, you will have a solid understanding of the necessary steps to ensure the safety of both operators and the surrounding workspace. Table of Contents: 1. Importance of CNC Machine Risk Assessment. 2. Common Hazards Associated with CNC Machines. Mechanical Hazards. Electrical Hazards. Ergonomic Hazards.

A machine risk assessment identifies potential machine hazards, their severity, and how frequently people may be exposed to them. After conducting a machine risk assessment, strategies and machine-guarding techniques can be implemented to minimize or avoid danger and harm to workers and machines.

Occupational risk assessment is a primary prevention and health task in every workplace. This assessment is mainly intended to ensure the safety of employees and to eliminate or partially reduce existing threats by taking appropriate remedies.Risk assessment tools such as risk matrices or risk scoring systems can be used to assign levels of risk to each hazard. In this section, we will provide an example risk assessment matrix specifically designed for CNC machines.

In order to design machines that are safe to operate and easier to keep within budget, the machine safety lifecycle helps manufacturing facilities identify safety hazards and mitigate risk to build safer machines before their installation and startup. A machine safety risk assessment (SRA) is the first step in the machine safety lifecycle.

The paper presents the results of the occupational risk assessment carried out on the example of a CNC ma-chine operator by means three-stage methods in accordance with the PN-N-18001,.Article highlights the importance of using methods of risk assessment as well as the importance of the security evaluation in manufacturing companies. This article provides an overview of the most widely used risk assessment methods and specifically referred to point method, which is one of the most widely used risk assessment methods. Here’s a five-step process to perform a safety risk assessment. Putting forth the effort in this stage will decrease the likelihood of problems arising in the future. 1. Get your team ready..

The first step in establishing safety protocols is conducting a thorough risk assessment of the CNC operation area. Identify potential hazards such as sharp edges, moving parts, or electrical risks. Once these hazards are identified, appropriate measures can be implemented to minimize the risks involved.Different CNC machines and tasks have unique risks associated with them. This section will discuss the importance of conducting job-specific risk assessments, including identifying hazards, evaluating risks, and implementing appropriate control measures.

electrical enclosure hardware

By the end of this guide, you will have a solid understanding of the necessary steps to ensure the safety of both operators and the surrounding workspace. Table of Contents: 1. Importance of CNC Machine Risk Assessment. 2. Common Hazards Associated with CNC Machines. Mechanical Hazards. Electrical Hazards. Ergonomic Hazards. A machine risk assessment identifies potential machine hazards, their severity, and how frequently people may be exposed to them. After conducting a machine risk assessment, strategies and machine-guarding techniques can be implemented to minimize or avoid danger and harm to workers and machines. Occupational risk assessment is a primary prevention and health task in every workplace. This assessment is mainly intended to ensure the safety of employees and to eliminate or partially reduce existing threats by taking appropriate remedies.Risk assessment tools such as risk matrices or risk scoring systems can be used to assign levels of risk to each hazard. In this section, we will provide an example risk assessment matrix specifically designed for CNC machines.

In order to design machines that are safe to operate and easier to keep within budget, the machine safety lifecycle helps manufacturing facilities identify safety hazards and mitigate risk to build safer machines before their installation and startup. A machine safety risk assessment (SRA) is the first step in the machine safety lifecycle. The paper presents the results of the occupational risk assessment carried out on the example of a CNC ma-chine operator by means three-stage methods in accordance with the PN-N-18001,.

Safety Risk Assessment in CNC Machining

Lathe Risk Assessment Template

Article highlights the importance of using methods of risk assessment as well as the importance of the security evaluation in manufacturing companies. This article provides an overview of the most widely used risk assessment methods and specifically referred to point method, which is one of the most widely used risk assessment methods. Here’s a five-step process to perform a safety risk assessment. Putting forth the effort in this stage will decrease the likelihood of problems arising in the future. 1. Get your team ready..

electrical enclosure dwg

Lathe Machine Definition, Types, Hazards, and Control

Founded in Salt Lake City, Utah in 2021, THECNCSOURCE is a veteran owned .

business risk assessment cnc machine|CNC Safety 101: Your Checklist for Secure Operations