billit of carbon fiber for cnc machine That's right, you heard right, "billet" carbon fibre. Actually not a billet of solid material, but 250 layers of carbon/resin cloth autoclaved into a 20" square about 2" thick with . $49.30

0 · water jet cutting carbon fiber

1 · how to cut carbon fibre

2 · end mill for carbon fiber

3 · desktop cnc for carbon fiber

4 · cnc carbon fiber sheets

5 · cnc carbon fiber cutting service

6 · carbon fiber machining near me

7 · carbon fiber cnc cutting

Vintage UNION Steel Tackle / Utility / Tool Box - Blue Model 5313 - Made in USA Great looking and built to last! Steel box by Union with a divided tray . more - perfect for fishing tackle or whatever small household hardware you might .

That's right, you heard right, "billet" carbon fibre. Actually not a billet of solid material, but 250 layers of carbon/resin cloth autoclaved into a 20" square about 2" thick with . Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes.

One of the most effective methods of shaping and manipulating carbon fiber is through CNC machining. In this comprehensive guide, we will delve into the world of CNC machining carbon . That's right, you heard right, "billet" carbon fibre. Actually not a billet of solid material, but 250 layers of carbon/resin cloth autoclaved into a 20" square about 2" thick with an 8" diameter 1" thick disc on top.Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes.

Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining.One of the most effective methods of shaping and manipulating carbon fiber is through CNC machining. In this comprehensive guide, we will delve into the world of CNC machining carbon fiber, exploring the techniques, tips, and best practices to achieve quality results. Carbon Fiber Blocks and Billets. Our carbon fiber blocks and billets boast a lower density and a higher strength-to-weight ratio than traditional materials, making them the superior choice for products that face frequent wear-and-tear or where weight is at a premium. Machining carbon fiber promises superior-quality finished components characterized by lightness and rigidity. It allows you to craft unique carbon fiber constituents in line with your specific use requirements. During machining, you are less likely to experience heating, which can damage your workpiece and degrade your machining tool.

The versatility of 5-axis machining carbon fiber billets unlocks new possibilities for the design and manufacturing of carbon fiber parts. Tooling techniques allow precise dimensions to be hit repeatably. Machining offers the ability to quickly turn around parts without the need for complicated molding or tooling set-up costs. Detailed tutorial explaining how to generate toolpaths using Autodesk Fusion 360, configure CAM setting and a desktop CNC router to make your own precision cut carbon fibre parts. This tutorial will assist those wishing to learn how to cnc carbon fibre.

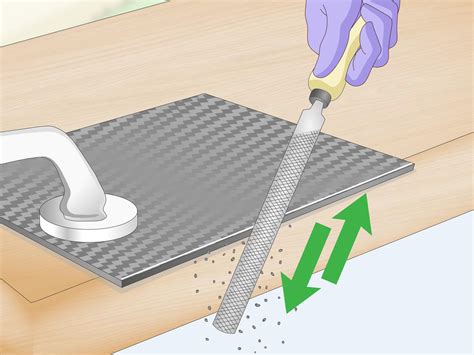

Typically, machining carbon fiber requires routing. Also, milled with standard metal machining methods. Higher spindle speeds and lower feed rates are required for proper milling. Adjusted feed rates minimize heat generation. Lower heat is desirable to avoid damaging the carbon fiber. CNC milling carbon fiber plates requires careful consideration of the material’s unique properties, precise tool selection, and optimized cutting parameters. By understanding how to prepare your CNC machine, manage cutting conditions, and implement proper finishing techniques, you can achieve accurate and clean cuts while avoiding common . That's right, you heard right, "billet" carbon fibre. Actually not a billet of solid material, but 250 layers of carbon/resin cloth autoclaved into a 20" square about 2" thick with an 8" diameter 1" thick disc on top.

Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes. Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining.

One of the most effective methods of shaping and manipulating carbon fiber is through CNC machining. In this comprehensive guide, we will delve into the world of CNC machining carbon fiber, exploring the techniques, tips, and best practices to achieve quality results. Carbon Fiber Blocks and Billets. Our carbon fiber blocks and billets boast a lower density and a higher strength-to-weight ratio than traditional materials, making them the superior choice for products that face frequent wear-and-tear or where weight is at a premium. Machining carbon fiber promises superior-quality finished components characterized by lightness and rigidity. It allows you to craft unique carbon fiber constituents in line with your specific use requirements. During machining, you are less likely to experience heating, which can damage your workpiece and degrade your machining tool.

water jet cutting carbon fiber

The versatility of 5-axis machining carbon fiber billets unlocks new possibilities for the design and manufacturing of carbon fiber parts. Tooling techniques allow precise dimensions to be hit repeatably. Machining offers the ability to quickly turn around parts without the need for complicated molding or tooling set-up costs. Detailed tutorial explaining how to generate toolpaths using Autodesk Fusion 360, configure CAM setting and a desktop CNC router to make your own precision cut carbon fibre parts. This tutorial will assist those wishing to learn how to cnc carbon fibre.

1953 chevy truck sheet metal

Typically, machining carbon fiber requires routing. Also, milled with standard metal machining methods. Higher spindle speeds and lower feed rates are required for proper milling. Adjusted feed rates minimize heat generation. Lower heat is desirable to avoid damaging the carbon fiber.

how to cut carbon fibre

end mill for carbon fiber

The EBJ Series is a submersible conduit-mounted junction box for underwater electrical connections. Ideally used for lights with 16/3 cable. Looking for help with your project?

billit of carbon fiber for cnc machine|carbon fiber machining near me