complex cnc milling parts This guide aims to explain more about CNC machining complex parts and provide quick and accessible design tips for milling. Several factors can make some parts more challenging to machine than others. Parts that require multiple setups with various steps can be a . Woodworking CNC Machines Laguna offers CNC Routers , CO2 lasers , Edgebanders , and Joinery Machines for your woodshop. Our industry-leading woodworking machinery were designed and developed, leveraging our 40 years of experience in the woodworking field.

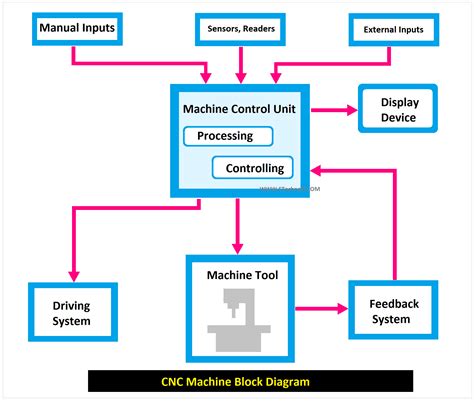

0 · schematic diagram of cnc machine

1 · milling machine parts diagram

2 · homemade cnc parts

3 · cnc milling machine parts names

4 · cnc mill parts diagram

5 · cnc mill diagram

6 · cnc machine parts list pdf

7 · cnc horizontal milling for dummies

Visit Our Shop or Call Us for Pricing Information. Some of our clients. Like what you see? Get in touch. Call us:956-784-9794. Contact us today. Working Sheet Metal. 1040 Valley Blvd, Alamo, TX 78516.

schematic diagram of cnc machine

CNC milling is a complex CNC machining process involving various components that work together to create precise parts with desired surface finishes. The CNC controller, column and base structure, power feed .In this article, we discuss the types of complex parts you can fabricate and manufacture using CNC — and how Fictiv can manufacture your custom CNC parts, on demand. It’s critical to know how CNC machining works before you design a part to be CNC machined.

This guide aims to explain more about CNC machining complex parts and provide quick and accessible design tips for milling. Several factors can make some parts more challenging to machine than others. Parts that require multiple setups with various steps can be a .

electrical distribution box pakistan

CNC milling is a complex CNC machining process involving various components that work together to create precise parts with desired surface finishes. The CNC controller, column and base structure, power feed mechanism, axes and tools are all essential for achieving accuracy and precision in the machining operations. Complex CNC machining refers to the use of computer numerical control (CNC) machines to create complex, intricate, and precise parts and components. In complex CNC machining, the parts being produced typically have complex geometries and may require multiple steps and operations to achieve the desired shape and accuracy. At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward.For complex and time-sensitive machined parts, 5-axis CNC machines offer unparalleled flexibility and speed. 3ERP’s experienced team can help bring your ideas to life, from rapid prototypes to end-use parts for safety-critical applications.

Learn about complex CNC parts, what makes a CNC part complex from a geometry perspective and our best tips for reducing geometric complexity. Read now. From simple planar parts to demanding, highly complex curved geometries, it’s vital to choose the correct CNC machine for the job. Different types of CNC machines exist and can be used for different parts.

CNC machined parts can often vary in complexity. It ranges from simple planar features to demanding, complex curved geometries. Thus, it’s vital to choose the correct CNC machine. Different types of CNC machines with different features are available in the market. But, a very few of them can be beneficial for complex parts.A Gosiger applications engineer offers 7 tips for CNC machine shops who wish to expand their businesses by milling complex parts for aerospace, medical and other industries.

In this article, we discuss the types of complex parts you can fabricate and manufacture using CNC — and how Fictiv can manufacture your custom CNC parts, on demand. It’s critical to know how CNC machining works before you design a part to be CNC machined.This guide aims to explain more about CNC machining complex parts and provide quick and accessible design tips for milling. Several factors can make some parts more challenging to machine than others. Parts that require multiple setups with various steps can be a . CNC milling is a complex CNC machining process involving various components that work together to create precise parts with desired surface finishes. The CNC controller, column and base structure, power feed mechanism, axes and tools are all essential for achieving accuracy and precision in the machining operations. Complex CNC machining refers to the use of computer numerical control (CNC) machines to create complex, intricate, and precise parts and components. In complex CNC machining, the parts being produced typically have complex geometries and may require multiple steps and operations to achieve the desired shape and accuracy.

At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward.For complex and time-sensitive machined parts, 5-axis CNC machines offer unparalleled flexibility and speed. 3ERP’s experienced team can help bring your ideas to life, from rapid prototypes to end-use parts for safety-critical applications.

Learn about complex CNC parts, what makes a CNC part complex from a geometry perspective and our best tips for reducing geometric complexity. Read now.

From simple planar parts to demanding, highly complex curved geometries, it’s vital to choose the correct CNC machine for the job. Different types of CNC machines exist and can be used for different parts.

CNC machined parts can often vary in complexity. It ranges from simple planar features to demanding, complex curved geometries. Thus, it’s vital to choose the correct CNC machine. Different types of CNC machines with different features are available in the market. But, a very few of them can be beneficial for complex parts.

electrical enclosure 6 x 12 x 36

At Woodward Fab, our metal fabrication machines and tools are designed to ensure durability, enhanced performance, and long-lasting service. These products are extremely reliable and are manufactured in adherence to industry .

complex cnc milling parts|cnc mill diagram