electrical box inspection In this post, we share a free electrical panel inspection checklist for technicians to use during electrical installations, inspections, or maintenance visits. It includes the following sections: General inspection. Panel and breakers. Wiring. . CNC milling machines can produce complex part surfaces that would be virtually impossible to produce with manual milling machines. vertical machining center (VMC). Notice the similarities to a manual vertical milling machine. horizontal machining center (HMC). Notice the orientation of the spindle, table, and ATC.

0 · electrical inspection requirements

1 · electrical inspection procedure

2 · electrical inspection outlet requirements

3 · electrical inspection circuits

4 · electrical inspection checkpoints

5 · electrical inspection checkpoint wiring

6 · electrical inspection checklist pdf

7 · electrical checkpoint box height

There are five common types of sheet metal joints that are extremely common across the industry, all with varying uses and advantages.

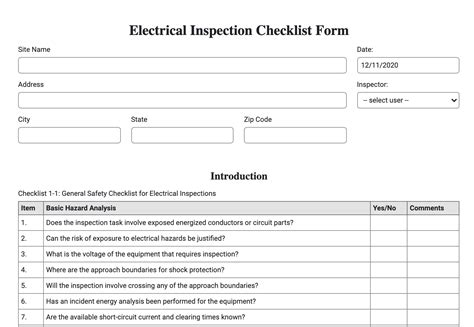

This guide contains 77 most important electrical inspection checklists taken from the Electrical Inspection Manual with Checklists. The checklists are in PDF format and can be completed electronically or printed .

All electrical enclosures are appropriate for the environment that they are exposed to. Electrical boxes, breaker panels, and electrical disconnects are in good repair and without obvious .

Electrical safety inspections are conducted to assess the condition and functionality of a property's electrical systems. These inspections are designed to identify potential hazards, such as faulty wiring, outdated panels, .

In this post, we share a free electrical panel inspection checklist for technicians to use during electrical installations, inspections, or maintenance visits. It includes the following sections: General inspection. Panel and breakers. Wiring. . Electrical boxes: Your electrical boxes must be large enough to accommodate the number of wire conductors necessary and be installed flush with the wall. Box heights: Electrical panels, receptacles/outlets, and switches . Your electrician will first and foremost want to make sure your home electrical wiring is done safely and that everything is in order. Three important elements of a safety checklist include checking for code violations, .Steps for an Electrical Inspection: Step 1: Check the electrical box outside. A bad connection here could explain any issues inside. Look for any glaring problems like any corrosion on the wiring, exposed wires, a weak connection from the .

Free NFPA fact sheet on best practices for the electrical inspection process, from outlet spacing and outlet box fill to securing wiring and wiring methods.The purpose of the rough-in inspection is to verify the proper installation of all outlet boxes, cables, wiring, and conduit. Inspectors need both physical and visual access to all new electrical components.

Electrical boxes: Inspectors will check to see that all electrical boxes are flush with the wall and that they are large enough to accommodate the number of wire conductors they will contain, along with whatever devices will be contained. This guide contains 77 most important electrical inspection checklists taken from the Electrical Inspection Manual with Checklists. The checklists are in PDF format and can be completed electronically or printed and used as hard copy.All electrical enclosures are appropriate for the environment that they are exposed to. Electrical boxes, breaker panels, and electrical disconnects are in good repair and without obvious physical damage.

Electrical safety inspections are conducted to assess the condition and functionality of a property's electrical systems. These inspections are designed to identify potential hazards, such as faulty wiring, outdated panels, or overloaded circuits.In this post, we share a free electrical panel inspection checklist for technicians to use during electrical installations, inspections, or maintenance visits. It includes the following sections: General inspection. Panel and breakers. Wiring. Grounding and bonding. Safety. Documentation and labels. Notes and observations. Recommendations . Electrical boxes: Your electrical boxes must be large enough to accommodate the number of wire conductors necessary and be installed flush with the wall. Box heights: Electrical panels, receptacles/outlets, and switches must be at a proper, safe height. Your electrician will first and foremost want to make sure your home electrical wiring is done safely and that everything is in order. Three important elements of a safety checklist include checking for code violations, inspecting your fuse box or circuit box, and testing voltage and surge protection across the system.

cnc machine listed companies in india

Steps for an Electrical Inspection: Step 1: Check the electrical box outside. A bad connection here could explain any issues inside. Look for any glaring problems like any corrosion on the wiring, exposed wires, a weak connection from the house to the power lines, etc. Step 2: .Free NFPA fact sheet on best practices for the electrical inspection process, from outlet spacing and outlet box fill to securing wiring and wiring methods.

The purpose of the rough-in inspection is to verify the proper installation of all outlet boxes, cables, wiring, and conduit. Inspectors need both physical and visual access to all new electrical components.

Electrical boxes: Inspectors will check to see that all electrical boxes are flush with the wall and that they are large enough to accommodate the number of wire conductors they will contain, along with whatever devices will be contained.

cnc machine lead time

This guide contains 77 most important electrical inspection checklists taken from the Electrical Inspection Manual with Checklists. The checklists are in PDF format and can be completed electronically or printed and used as hard copy.All electrical enclosures are appropriate for the environment that they are exposed to. Electrical boxes, breaker panels, and electrical disconnects are in good repair and without obvious physical damage. Electrical safety inspections are conducted to assess the condition and functionality of a property's electrical systems. These inspections are designed to identify potential hazards, such as faulty wiring, outdated panels, or overloaded circuits.In this post, we share a free electrical panel inspection checklist for technicians to use during electrical installations, inspections, or maintenance visits. It includes the following sections: General inspection. Panel and breakers. Wiring. Grounding and bonding. Safety. Documentation and labels. Notes and observations. Recommendations .

Electrical boxes: Your electrical boxes must be large enough to accommodate the number of wire conductors necessary and be installed flush with the wall. Box heights: Electrical panels, receptacles/outlets, and switches must be at a proper, safe height. Your electrician will first and foremost want to make sure your home electrical wiring is done safely and that everything is in order. Three important elements of a safety checklist include checking for code violations, inspecting your fuse box or circuit box, and testing voltage and surge protection across the system.Steps for an Electrical Inspection: Step 1: Check the electrical box outside. A bad connection here could explain any issues inside. Look for any glaring problems like any corrosion on the wiring, exposed wires, a weak connection from the house to the power lines, etc. Step 2: .Free NFPA fact sheet on best practices for the electrical inspection process, from outlet spacing and outlet box fill to securing wiring and wiring methods.

electrical inspection requirements

electrical inspection procedure

cnc machine job work in chennai

A: There are indeed various types of 5-axis CNC machines, such as universal machines, horizontal machining centers, specialized lathes, and so on. Depending on the machining requirements, these types possess advantages, such as enhanced flexibility or compatibility with certain types of workpieces that may be better than others.

electrical box inspection|electrical inspection checklist pdf