spinning in sheet metal Spinning, also known as spin forming or metal spinning, is a specialized sheet metal forming process used to create cylindrical or conical shapes from flat sheets or pre-formed blanks. This .

$5.99

0 · what is metal spinning process

1 · tool rest for metal spinning

2 · stainless steel metal spinning

3 · metal spinning vs deep drawing

4 · metal spinning process step by

5 · metal craft spinning and stamping

6 · manual metal spinning

7 · industrial metal spinning

I just purchased a 1985 Fleetwood Tioga and the 110 volt outlet above the dinning table has no power. I traced the wire back behind the shower and bathroom into a space behind the converter box with a .

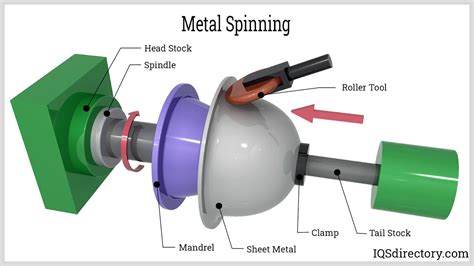

The term Metal Spinning refers to a group of forming processes that allow for the production of hollow, axisymmetric metal components. Metal Spinning is one of the oldest techniques for the chipless production of circular .

Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Spinning can be performed by hand or by a CNC lathe. The metal spinning trade is one that dates back to antiquity and was a skill us.

Metal spinning—also referred to as metal turning or spin forming—is a forming process in which a flat metal disc is turned into a hollow component with a circular cross-section. Metal spinning, also known as spin forming or spinning, is a metalworking process that forms a sheet or tube of metal into an axially symmetric part. This process involves rotating a metal disc or tube at high .Metal spinning lathes fall into three general categories, each particularly suited for certain applications depending upon the material and dimensions of the workpieces. Manual Spinning. lathes can accommodate a wide range of .

Spinning, also known as spin forming or metal spinning, is a specialized sheet metal forming process used to create cylindrical or conical shapes from flat sheets or pre-formed blanks. This . Metal spinning is a near-net-shape forming process used to produce axisymmetric hollow parts, usually with circular cross-sections, that involves forming sheet metal over a rotating mandrel with the help of one or . Metal spinning is a versatile, symmetrical rotational forming process for sheet metal that finds widespread application across diverse industries. This technique involves plastically deforming a rotating metal blank .Shear spinning involves forming the work over the mandrel, causing metal flow within the work. This metal flow will act to reduce the thickness of the work as it is formed. The initial diameter of the work can be smaller in shear spinning.

what is metal spinning process

Metal spinning, also known as spin forming or spinning, is a metalworking process that forms a sheet or tube of metal into an axially symmetric part. This process involves rotating a metal disc or tube at high .A metal spinning of steel is sturdier and more ridged than a stamped metal sheet of steel of the same thickness. A byproduct of the spinning procedure is an increased rigidity, further assisted by stiffening beads and radii.Metal spinning, also called conventional spinning or just spinning, is the forming of an axis-symmetric part over a rotating mandrel. Force is delivered by a tool with a rounded end or a roller. . This causes the sheet metal work to be wrapped .

tool rest for metal spinning

Royce Metal Products is leading the way in metal spinning and precision metal fabrication. Our metal spinning expertise is a result of 75 years in the business. Call 416-742-9641 for more information. Metal spinning is a sheet metal forming process that uses rollers to form axisymmetric parts over a rotating mandrel. There are three main types: conventional spinning, shear spinning, and tube spinning. Spinning can be done hot or cold and involves placing a metal blank against a mandrel and using tools to deform the material into shape as it .

Metal spinning—also referred to as metal turning or spin forming—is a forming process in which a flat metal disc is turned into a hollow component with a circular cross-section. The flat metal disc—i.e., the blank—is fixed to a spinning lathe. While Manual Metal spinning

1. Introduction. Sheet metal spinning of cylindrical cups is a traditional forming process, however, due to the flexibility of the process; it has undergone a renaissance in recent years and has developed into a versatile process for producing lightweight components [1], [2], [3].In this process, a rotating sheet metal disk is deformed over a cylindrical mandrel into a cup .A sheet metal spinning machine also known as spin forming or spinning, sheet metal spinning machine is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Our sheet metal spinning machines are made originally by our KDM professional engineers. KDM has 20 years of quality .Spinning sheet metal on the lathe is an excellent means for quickly prototyping round hollow metal forms (primarily the realm of expensive sheet metal stamping machinery). A levered force is applied uniformly to the sheet metal by rotating the metal and its intended form (mandrel) at very high rpms, thus the sheet metal is deformed evenly .

The mechanics of sheet metal spinning involve a combination of controlled force, material plasticity, and manipulation on a rotating form. Here’s a breakdown of the key aspects: 1. Material: Sheet metal is the starting point. The specific type chosen depends on the desired final product’s properties. Common options include aluminum, steel . Learn how a lathe is used to form a piece of sheet metal into a bowl. The piece of metal and a buck (the bowl form) are secured on a lathe. As the lathe spin. Metal spinning, also known as spin forming or spinning, is a metalworking process that forms a sheet or tube of metal into an axially symmetric part. This process involves rotating a metal disc or tube at high speed while applying pressure with a tool to shape the metal around a .

Spinning sheet metal. Click on thumbnails to see larger images : More pictures to come once the tanks are completed. Return to card catalog page .Metal Spinning Versus Flow Forming. . The large majority of spun parts can be formed by starting with a blank disk trimmed from standard commercial sheet metal. When starting with a disk blank is not a viable option, normally because . Axial Sheet Metal Spinning with CNC Forming Machine. Tooling plays a critical role in metal spinning, directly impacting the quality, precision, and efficiency of the final product. The proper selection and design of tooling components, including mandrels, rollers, and dies, are crucial for achieving the desired part geometry and surface finish

cantex 8x8 junction box

Spinning sheet metal is a metalworking process that transforms flat sheets of metal into hollow, rotationally symmetrical shapes. It’s a versatile and cost-effective technique used for a wide range of products, from simple kitchenware .

In spinning, the sheet metal discs are formed into rotationally symmetrical hollow shapes. The blank is clamped between the shaped spinning mandrel and the tailstock of the spinning machine and rotated by the main drive. The metal disc and the mandrel rotate together and the spinning roller makes contact with the outer face of the workpiece. Using the installation tool I have them very snug in the metal hole. After removing the tool I insert my bolt, a couple of turns and the rivnut starts to spin in the sheet metal hole. Only way to remove them is to drill them out. I think they are a great idea, but useless if I can’t get them to sit still while accepting a bolt. Keywords: Sheet metal spinning, Wrinkling, Predictive process analysis 1 INTRODUCTION Sheet metal spinning is originally a very old manufacturing process for which long-term knowledge and experience of a skillful worker is essential. Nowadays CNC-machine tools are used and the process is getting increasing importance in many fields of .

Axial Sheet Metal Spinning with CNC Forming Machine. Tooling plays a critical role in metal spinning, directly impacting the quality, precision, and efficiency of the final product. The proper selection and design of tooling components, including mandrels, rollers, and dies, are crucial for achieving the desired part geometry and surface finish

Metal Spinning Tutorial P ROCESS Spinning sheet metal on the lathe is an excellent means for quickly . Sheet metal can be spun in thicknesses of 0.040" to 0.100" with hand tools. Stainless steel is even more elastic (stretching before tearing) than aluminum (50%-68% elongation!) but requires significantly more force to form. . Sheet Metal Spinning is a flexible manufacturing process for axially-symmetric hollow components. While the process itself is already known for centuries, process planning is still based on .

We are manufacturer of Spinning Metal in China, if you want to buy Sheet Metal Processing Product, Ice Bucket, Metal Table Leg, please contact us. . Metal Spinning ; Sheet Metal Processing ; Metal Processing ; Lamp Shade ; Stretch Stamping; Contact Us. Tel: +86-0575-82591566; Mobile Phone: 8613735325636;

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking Operations Sheet metal spinning is an incremental forming process for producing axisymmetric thin-walled parts through continuous local deformation under the action of rollers. While studying the spinning process by finite element (FE) method, a critical bottleneck is the enormous simulation time. For beating off this challenge, a novel multi-mesh method .

Spinning, also known as spin forming or metal spinning, is a specialized sheet metal forming process used to create cylindrical or conical shapes from flat sheets or pre-formed blanks. This technique is particularly valuable for producing symmetrical components such as domes, cones, and cylindrical shells.

stainless steel metal spinning

Junction boxes are must-have units at home as they protect against electrical issues. Here are a few of the most common junction boxes and where to use them.

spinning in sheet metal|metal spinning vs deep drawing