what is nesting parts for cnc router Nesting is a strategy used in computer numerical control (CNC) router cutting to maximize the use of material by arranging parts in the most efficient way possible on a sheet of material. It involves placing the parts in . Swiss carved box “Helvetiorum Fidei ac Virtuti” circa 1850Swiss carved box “Helvetiorum Fidei ac Virtuti” circa 1850This is a museum item reallyThe solid oak box depicts the monument that is carved in.from 136759740

0 · what is nesting in cnc

1 · types of cnc nesting

2 · nesting in cnc machine

3 · how does nesting work

4 · cnc static nesting

5 · cnc nesting software

6 · cnc nesting process

7 · cnc nesting diagram

$179.99

what is nesting in cnc

CNC Nesting (CNC Cutting Method) – Simply Explained. Nesting is an important aspect of production, ensuring work is completed efficiently in .

CNC nesting is the process of finding the most space-efficient layout to arrange the cutting patterns on workpieces of the desired length. CNC nesting algorithms are optimized to find the best fit and this becomes .

Nesting, quite simply, aims to reduce material waste by laying patterns out in a certain way when cutting out multiple parts. However, whilst this may sound straightforward, it’s often more complex than you’d think.Nesting with CNC routers is a technique that involves arranging parts to be cut out from a single sheet of material in such a way as to minimize waste while maximizing output. This process .

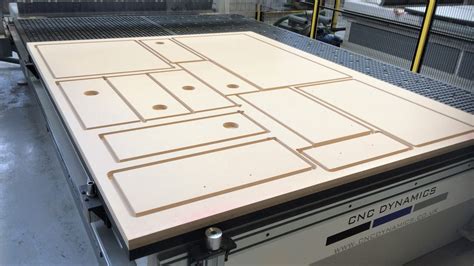

Nesting is a strategy used in computer numerical control (CNC) router cutting to maximize the use of material by arranging parts in the most efficient way possible on a sheet of material. It involves placing the parts in . A nesting CNC router operates through a combination of software and mechanical components. The process begins with creating a digital design using CAD (Computer-Aided . What is a nesting CNC? Nesting CNC refers to the process of laying a cutting pattern to reduce cutting time and the amount of waste involved. It aims to produce as many parts as possible from as few materials as possible. . Nesting is an intelligent process for arranging parts on panel material. It optimizes material use, reduces waste, and thus maximizes yield. Nesting has many advantages, .

types of cnc nesting

The nesting CNC router is mainly cutting equipment used in the production of panel furniture. The main functions include automatic typesetting, engraving, automatic loading and unloading, special-shaped cutting, vertical .I found a really great software for nesting parts for lasercutting or cnc routing. It is amazing how well it can nest parts to a sheet at any given size . . on eBay - and now I'm keen to build a similar box for my own mitre set. I've seen similar .Nesting CNC Router Machine. . Automatic lubrication is an option that ensures the continuous lubrication of the nesting cnc router machine’s main moving parts without the need for operator intervention. The double Y-axis motorization .

Nesting works better for small to medium workshops working in particular on custom projects. It is much faster because you do not need a saw to cut the parts beforehand. Nor do you need to load each part separately onto the machine. . CNC nesting can be divided into two main types of nesting – static and dynamic nesting. Static nesting is used when a low number of unique parts are to be produced in high volumes. The parts remain the same therefore the nesting pattern also remains the same that is used on different sheet metals. Nesting is a strategy used in computer numerical control (CNC) router cutting to maximize the use of material by arranging parts in the most efficient way possible on a sheet of material. It involves placing the parts in such a way that they use as little material as possible and minimize waste.

Along with some other considerations we have landed on a CNC router and wondering if anyone has any direct experience with nesting packages that are out there? Design work is in solidworks, we use the pro package with PDM. Not looking for the cheap/free clunky option, more for the best workflow/efficiency and budget is kind of open ended within .

CNC nest cutting router bits features: Material: KCR05 TCT carbide from Luxembourg Fast feeding speed: 12-18m/min Spindle speed: 18000-24000rpm Nearly hundreds of sheets can be nest cut Suitable for drilling, cutting, slotting, grooving, nesting, trimming, etc. RicoCNC is a professional CNC router bits supplier, and sell the bits more than 8 years, nearly all CNC . The nesting cnc router is the gantry machining center designed for Nesting applications of wood and wood-based materials, but also plastic based and non-ferrous materials machining . CNC router has many parts. Despite this, they do not need extensive lubrication. However, if you fail to observe the activity, you will witness machine . The CNC router price of this nesting CNC could reach ,000, but it is worthwhile for the the panel furniture manufacturers with a production volume. Highest-end and industrial CNC router cost over 0,000. . 3.6 Repair & maintenance, wear of parts. CNC router manufacturers usually provide a warranty period. For example, we provide a 12 .

Should a router on a machining center perform the same tasks as a CNC router? Are the differences between the two primarily in the part holding methods? Is there a big difference in software and controller between the two? Can nesting only be accomplished on a CNC router? Are pre cut cabinet parts better processed on a PTP?In a word, CNC nesting technology aims to produce as many parts as possible with as little material as possible. . CNC router nesting machine is used to carve all kinds of two-color plate signs, plexiglass, 3D billboards, two-color figure statues, embossed medals, organic plate embossing, 3D door characters, etc. .

Use a compression for the larger parts that you know won't move and a really sharp Vortex Xp or equivalent 1/4" diameter down-shear for the small parts. If your software allows it, space the really small parts out so there is about .5-.75" thick wood frame left between cut profiles. Nesting, or nested-based manufacturing, is used in woodworking to cut and divide wood or wood-based panel materials efficiently, typically using a CNC machine. Nesting can offer advantages over conventional panel dividing or cutting, especially for .

The nesting CNC router is mainly cutting equipment used in the production of panel furniture. The main functions include automatic typesetting, engraving, autom . Whether it is about the machine or the parts of the nesting CNC router, as well as the operation, purchase, and maintenance of the nesting machine, this article is helpful to you .

nesting in cnc machine

People have been nesting parts on CNC routers for many years before it became a buzzword. By the way, you never hear the nested based router discussed with plastic fabricators. Talk to some of them and find out how many point to point or Pod and rail machines they use. I think you will find that nested, like contributor S said, is a sales . Hey All I Was wondering the best way to add multiple part bodies to a file so that I can nest them for cnc routing on a large sheet goods. Currently i have four different parts all originally .ipt bodies that I want to do this with. My Problem however is whenever I drag and drop the files into a new design and begin tool pathing (especially with drill paths) the tool wants to .Head for Your CNC . A 1/8” spiral upcut spiral bit works great for small, detailed work like these Christmas trees. Mount your material on the CNC. Zero the X, Y and Z axes. Run the toolpath. A successful onion skin toolpath. Setting the . The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines. Nesting CNC Router. A CNC nesting router machine is an industrial automatic wood cutting machine with computer numerical controller, which has the ability of feeding, cutting and unloading in furniture customization.

A 3-axis CNC router can only move on 3 linear axes: X, Y, and Z – like a Cartesian 3D printer. But, there are also 3 rotational axes: A, B, and C. . Nesting software arranges these parts to increase cutting efficiency and reduce waste on a material sheet. This is done to reduce costs by saving excess waste through optimal cut pattern design. The 3-axis CNC router is suitable for processing flat parts; the 4-axis CNC router is suitable for processing parts with specific angles; the 5-axis CNC router is suitable for processing parts of any complexity. When choosing a CNC router, comprehensive considerations need to be made based on actual needs and budget. For nested-based machining on a CNC router, the first step is to transport wooden board to the machine. These boards are then loaded onto the table of the CNC router and parts are machined directly from the sheet. Since the panel is held in place using a high-flow vacuum system, changing the hold on the different parts is not needed. Manufacturers that work with nesting CNC routers depend on optimal vacuum to hold down their parts firmly and consistently. Dependable hold-down capability is crucial to all jobs, but especially .

With a CNC router and a nesting program, there would be three tool changes to profile, drill, and cut out all 20 components. Also, keep in mind that a router uses much higher feed rates to produce these parts, so you will have them off the CNC much more quickly. And one more consideration: a CNC router operator can be getting the next sheet .

A variety of custom parts can be constructed using CNC machining. CNC routers are similar to CNC milling machines and the like, but they offer greater efficiency and reduce waste. What are the advantages of the CNC nesting machine? Because CNC router machines can carve with very hard and sharp tools, in addition to wood and cardboard materials . I explain what a cnc router is used for and a few different manufacturer enviorments you tend to find a CNC router in. . I was lucky enough to get my feet with CNC routers in an aerospace company and we cut many different parts on the router. . With the proper nesting software, cabinet parts on sheet stock will increase your yield.Here's a look at the quality-control problem of fuzzy cut edges in panels cut by a CNC router. December 3, 2010 . rather than nesting them on the router, because the rougher core from routing telegraphs through the PVC. . use 1/2" compression cutter, climb feed and make sure they have enough vacuum on the parts. Related Articles. Detailing .For CNC Routers, Point to Point Boring Machines and now Mill, Laser, Torch & Waterjet. Your CNC Router needs the best CAD/CAM software to be productive. With Router-CIM Automation Suite by CIM-TECH, you get best in class automated programming and nesting. When you compare features, the number of steps to make a program and nesting yields, and .

how does nesting work

cnc machine safety

They would use BIM drawing’s at the start of a job and we’d go in a shoot hangers for the whole building. I didn’t really start using hanger strap until I came down here to .

what is nesting parts for cnc router|cnc nesting diagram