types of pattern development sheet metal pattern development stretchout development • pattern • parallel-line development stretchout line measuring line radial-line . See more Welding and Metal Fabrication is a superb handbook for welders. It is authored by Larry Jeffus. The book explains all about developing skills to become a highly paid versatile welder.

0 · sheet metal pattern layouts pdf

1 · sheet metal pattern layout methods

2 · sheet metal layout software free

3 · sheet metal layout pdf

4 · sheet metal fittings layout drawing

5 · sheet metal development drawing pdf

6 · free sheet metal layout patterns

7 · free sheet metal layout books

Whether you’re a MIG welder, a TIG welder, or want a machine you can do both with, we have reviewed a range of different welders to help you narrow down a good choice for your next project. 1. Miller Electric 211 – Best MIG Welder.

Philippe Starck is a French designer who created a line of everyday items for Target. Design Guys, a Minneapolis-based fi rm, was asked to create the packaging for the Starck product line. . See morepattern development stretchout development • pattern • parallel-line development stretchout line measuring line radial-line . See more

Graphic design Engineering technology Marketing Problem solving Sketching and visualizing See moreDesigners are both creative and practical. A bachelor’s degree is required for most entry-level positions. Helpful high school courses include Eng . See moreUnderstand the layout and pattern-development processes. Elevation view – looking at the front or side of something, to have elevation (height), 2D. Element Line – a line representing an .

A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. .Parallel Line Development. The process of pattern development is the way we turn 2D sheets of metal into 3D objects. A parallel line is one of the basic forms of layout. We use it when . Pattern Development: Sheet Metal Level 1. This book covers all three forms of layout as well as geometric construction. It introduces the learner to the techniques used in parallel line, radial line, and triangulation. With videos .Advanced Pattern Development. By this time in your training, we are looking at advanced pattern development of various fittings. This will begin to introduce us to a combination of methods .

The process of pattern development is the way we turn 2D sheets of metal into 3D objects. A parallel line is one of the basic forms of layout. We use it when element lines (bends) on an .In Level 2 we will expand on previously learned processes in parallel line and radial line as well as a new technique in triangulation, developing pattern from elevation view instead of plan view.

It explains basic methods of drawing patterns for developing sheet metal and other types of protective covers commonly produced for wrap over insulation. The book does not attempt to . It introduces the learner to the techniques used in parallel line, radial line, and triangulation. With videos and animations, the learner has an opportunity to play, pause, and rewind as they practice these techniques. This .Pattern Development: Sheet Metal Level 4 . Advanced Pattern Development . begin to introduce us to a combination of methods and techniques and using them together in a process to create these types of fittings. It is essential to bring a complete understanding of various terms, techniques, and processes from years past, so to be able to link .

Book Description: This book covers all three forms of layout as well as geometric construction. It introduces the learner to the techniques used in parallel line, radial line, and triangulation. With videos and animations, the .the blank required to form the desired sheet metal component. Flat Pattern Development (FPD): It is the process of determining flat pattern for a sheet metal component corresponding to its neutral surface. The neutral surface is the surface within the sheet that is parallel to the inner and outer surfaces and on which the net stress of the .

Parallel Line Development. The process of pattern development is the way we turn 2D sheets of metal into 3D objects. A parallel line is one of the basic forms of layout. We use it when element lines (bends) on an object are indeed parallel. The two ends of the part must be the same.Use the elbow rule (# of pcs × 2 − 2) to find the number of gores.For our example, it is 4 × 2 − 2 = 6.Each end piece is made up of 1 gore and each middle piece is made up of two gores.; Use the angle of the elbow divided by the number of gores to find the miter angle. In our case, 90° ÷ 6 = 15°. Now that we know the miter angle is 15°, we can use an end gore and lay it out similar . For sheet metal components, there are a few papers on feature recognition and feature-based design, but all systems use 3-D models [12], [13], [14], [15].Apart from the feature recognition, flat pattern development is also an essential step to develop process plans for sheet metal components.

sheet metal pattern layouts pdf

In Parallel Line Pattern Development, we required parallel element line or bends. Some objects are of a conical shape and parallel line will not work on them. Rather, we will look at using Radial Line Pattern Development. In radial line, we develop patterns for shapes that have a taper, all element lines (bends) must radiate back to a common .Pattern Development: Sheet Metal Level 1. Triangulation When we looked at both parallel line and radial line pattern development, we saw fairly simple and limited layout process. We have conditions that must be met in order to use them. Triangulation is the process used when nothing else works. There are very few conditions in which .

electric panel box installation 320 a

Study with Quizlet and memorize flashcards containing terms like All lines must radiate from a common _____ for radial line development to be used, Radial line development on some objects is faster than triangulation, Radial Line development is use for _____ patters and more.Make sure the fitting is sized correctly. Remember some of the sizing rules for y-branches: the crotch height must be ¾ of the base diameter (or 1.5x the radius), the small openings must equal the large- A2 + B2 = C2 can be used to size the fitting correctly Draw a complete elevation view of 1 side of the fitting. The second side would be traced or a second pattern would be developed .

Study with Quizlet and memorize flashcards containing terms like pattern development, stretchout, development and more. . Types of Section views. 6 terms. elizabethfilipiak24. Preview. unit 5 lesson 3. 10 terms. ooddi0735. . the original part of pattern development from which flat patterns can be cut from flat sheet s of material and folded . Download Citation | Development of patterns from sheet materials | Many articles such as cans, pipes, elbows, boxes, ducting, and hoppers are manufactured from thin sheet materials. This chapter .Pt1. Introduction - https://youtu.be/VPwwbUz7p34Pt2. Square Based Pyramid Development - https://youtu.be/3h9uDY67NQ8Pt3. Frustrum of a Cone Development - htt. Pattern development is used in sheet metal and packaging industries. In sheet metal, patterns are used to cut and form metal sheets into objects like ducts and pans through bending and fastening. . Common types include cylindrical, truncated, conical, and pyramid patterns developed through parallel or radial line drawings. Patterns include .

Parallel Line Development. The process of pattern development is the way we turn 2D sheets of metal into 3D objects. A parallel line is one of the basic forms of layout. We use it when element lines (bends) on an object are indeed parallel. .This book covers all three forms of layout as well as geometric construction. It introduces the learner to the techniques used in parallel line, radial line, and triangulation. With videos and animations, the learner has an opportunity to .The chapter objectives are to explain how pattern development is used, identify methods for processing sheet metal patterns, describe general pattern development principles, discuss the three main types of pattern development, .The webpage provides information on developing patterns from sheet materials for engineering purposes.

Contact the Experts at Prescott Metal. There are many benefits to sheet metal finishing, and different types of sheet metal are better suited for certain conditions. If you have questions about sheet metal types, finishes, or uses, contact us at Prescott Metal, New England’s premier sheet metal fabrication shop. With over 100+ years of .The new metal worker pattern book; a complete course of instruction in the modern methods of developing and cutting the patterns for sheet metal work, giving the principles under-lying practically every problem that is likely to come up in practice and explaining the selection and use of drawing tools and linear and geometrical drawing so clearly that one who has had no .

Pattern Development: Sheet Metal Level 3. 6 Twisted Fitting Because the top and bottom are parallel, triangulation from plan view will be used. This is a much quicker way to develop the pattern, compared to using elevation view. Draw a plan view complete with element lines and labeling. Label the top with 1-4 and A-D for the bottom.

1 Construct Triangles – “Triangulation” When the Three Lengths Are Known (3-4-5) Draw a line equal to one of the known lengths. Set your compass to the second known length (6 inches) and swing an arc from one end of the line (point A).; Set your compass to the third known length (3 inches) and swing an arc from the other end (point B) of the line, crossing the first arc.20 Right Cone . Draw an elevation view.; Profile the base of the elevation view and divide it into six equal parts (see Divide a Circle Into 12 Equal Parts).; Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone.; Locate a radius point where you want to develop the pattern.

sheet metal pattern layout methods

Pattern development worksheet, has templates and demonstrates how sheet metal workers produce patterns before folding metals. Designed to be completed in a classroom using paper, but can be used for a range of other subjects that involve manipulating 3D shapes. Feel free to cut and paste any of the activities for your own style of sessions. Hi. I'm having an issue with a flat pattern not generating. After a quick check of the common reasons for failure, the material type and thickness seem to match the sheet metal default being used. The design intent got pretty murky through the development of the assmbly, and I just need a flat pattern to cut this part "Back plate_sheave box.ipt". Sheet metal work. In sheet metal work, different types of metal sheets are used. The sheets are specified by their standard gauge numbers. It is very essential to know the different uses and applications of these metal sheets. Tools used in the sheet metal work are; Measuring tools. Steel rule; Outside micrometer; Vernier caliper; Combination set

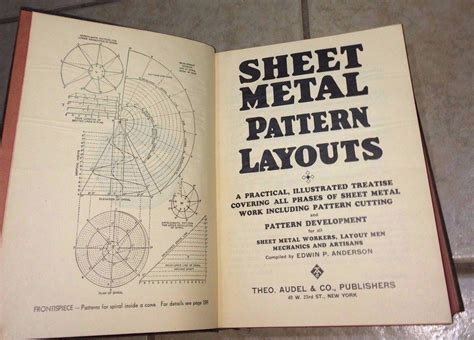

The new metal worker pattern book; a complete course of instruction in the modern methods of developing and cutting the patterns for sheet metal work, giving the principles underlying practically every problem that is likely to come up in practice and explaining the selection and use of drawing tools and linear and geometrical drawing so clearly that one, who has had no .

sheet metal layout software free

Elite Welding & Fabrication has over 20 years of combined fabrication and welding service. We offer mig and tig welding, CNC cutting and forming, and 3D CAD support, along with many other services.

types of pattern development sheet metal|sheet metal pattern layout methods