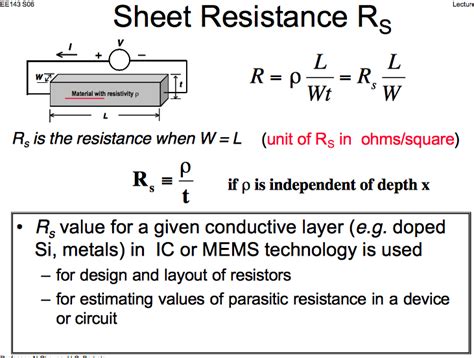

sheet resistance of metals the sheet resistance = (σ n t)-1 = R (L/W) = R N The sheet resistance is under the control of the process designer; the number of squares is determined by the layout and is specified by the IC designer. For average doping levels of 10 15 cm-3 to 10 19 cm-3 and a typical layer thickness of 0.5 µ m, the sheet resistance ranges from 100 k Ω . Barber Metals and Fabrication is a leading construction metal and steel supplier in Utah. We’re a one-stop shop; we supply, powder coat, and deliver steel supplies directly to you. Whether you’re a manufacturer, construction .

0 · what is a sheet resistance

1 · sheet resistance pdf

2 · sheet resistance geometry

3 · sheet resistance diagram pdf

4 · sheet resistance calculation

5 · how to measure sheet resistance

6 · how to find sheet resistance

7 · 4 point sheet resistance

Learn about junction box electrical wiring, including how to install and troubleshoot wiring connections in junction boxes for electrical circuits.

SURAGUS sheet resistance calculator convert single- and multi-layer systems according to sheet resistance, conductivity, thickness and resistivitythe sheet resistance = (σ n t)-1 = R (L/W) = R N The sheet resistance is under the control of the process designer; the number of squares is determined by the layout and is specified by the IC designer. For average doping levels of 10 15 cm-3 to 10 19 cm-3 and a typical layer thickness of 0.5 µ m, the sheet resistance ranges from 100 k Ω . Leveraging on the contact-end-resistance model applied to the transfer length method structure, we conduct a quantitative and comprehensive characterization of the molybdenum disulfide (MoS 2) contact interface with .High resolution 3D-printing of conductive inks has shown promise in enabling rapid prototyping for package scale interconnects and devices. If additive manufacturing becomes broadly adopted for package and chip-scale prototyping, it is critical to investigate contact resistance between printed materials and IC bond pad materials. In this work, contact resistance between direct-write .

sheet resistance of metals Hi, Why sheet resistance of matsl varies as the width of metal increases. (According to theory sheet resistance should remain constant). Reasons that I could think of, 1. Thickness variation because of CMP. 2. . Layer Sheet Resistance (W/o) Diffusion (silicided) 3-10 Diffusion (no silicide) 50-200 Polysilicon (silicided) 3-10 Polysilicon (no silicide) 50-400 Metal1 0.08 Metal2 0.05 . §AMI 0.6 µm process has 3 metal layers §Modern processes use 6-10+ metal layers §Example: Intel 180 nm process §M1: thin, narrow (< 3l) –High density cells §M2 .

As an example of calculating a volume's resistance, consider the drawing to the left. Assume 12 AWG copper wire with a resistivity (from the table) of 1.72x10-6 Ω

Download Table | Conductivity, skin-depth and sheet resistance of PCB Metals from publication: EM Modeling of Board Surface Finish Effect on High Speed PCB Performance | Printed circuit board (PCB . For sheet resistance measurement, the EC method is restricted to no less than about 100 nm of metal thickness (or about 10 Ω/sq., depending on the type of metal), due to the minimal eddy currents generated by extremely thin metal films.In copper cladded laminates copper foil is roughened to promote adhesion of the dielectric resin. Sheet resistance of rough metal surfaces increases as a function of frequency, thus increasing signal attenuation. In this paper we present measurements of the sheet resistance of rough metal surfaces on several commercially available copper cladded laminates and on metalized .Generally, for thin sheets, we measure sheet resistance by using a three point or four point probe method. Then, you can find the resistivity of the material by using a relation between sheet resistance, resistivity and thickness of the sheet. Sheet Resistance and the Calculation of Resistivity or Thickness Relative to Semiconductor Applications

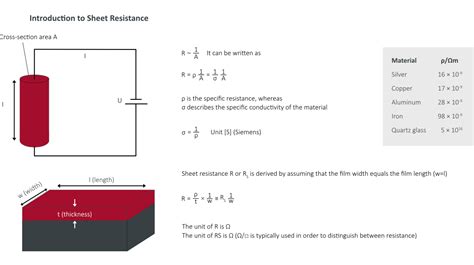

What Is Sheet Resistance? The resistance between the contacts is L / W has no units ρ / t should have units of ohms But . . . R ≠ ρ / t! Sheet resistance R sh = ρ / t (ohms / square) Resistance independent of the size of the square ohms W L A t L R ρ ρ = = R = (R sh )x (numberof squares) [ohms] W L . t . ρ . 5 squares . R. sh Hi, If we are using a 0.18u TSMC library does the library file have the spec for the current handling capability of a layer in A/m and also the sheet resistance so that we can do the manual calculation of the IR drop.If no then where do i get this info from? Sheet metal fabrication is a fundamental process in various industries, from automotive to aerospace, construction to electronics. Understanding the forces involved in sheet metal operations is crucial for ensuring the integrity and quality of the final product. . This is because thicker sheets offer more resistance to deformation due to the . i dont find any relationship between sheet resistance and metal spacing. sheet resistance is a property of that particular metal. it is fixed by foundry people. where as metal spacing is fixed by a physical design team of an ASIC . Jun 14, 2006 #8 J. jemmy Junior Member level 1. Joined Jun 7, 2003 Messages 18

another may not show a sheet resistance twice that of the thicker film. 4) Describe the interplay between transparency and sheet resistance for the 3 Cr film samples, and separately for the 2 TEC glass substrates. 5) Of the five films you .

In general, the four-point probe method is used to determine the sheet resistance of thin metal films, but in fact, resistance is the main electrical property assessed using this technique. In a four-point probe, the outer probes . The resistance of a length of metal is given by: Where ρ is the bulk resistivity of the material, L is the length, and A is the cross-sectional area as shown in the figure above. . If a material has a sheet resistance of 10 .The resistivity can be expressed using the SI unit ohm metre (Ω⋅m) — i.e. ohms multiplied by square metres (for the cross-sectional area) then divided by metres (for the length).. Both resistance and resistivity describe how difficult it is to make electrical current flow through a material, but unlike resistance, resistivity is an intrinsic property and does not depend on . The value of contact and sheet resistance of various metal electrodes to monolayer graphene is summarized in Table 1. 4. Conclusion. A reproducible process to fabricate monolayer graphene based transfer length method structures is presented. Five different metals (gold, nickel, nickel/gold, palladium and platinum/gold) were used to contact .

Sheet resistance is inversely proportional to the thickness of a film. Your 30 nm film should have about 5/3 higher sheet resistance than your 50 nm film. With films this thin there may be additional effects that would cause the 30 nm film sheet resistance to be even higher.The top heat-resistant metals set the benchmark for extreme heat tolerance, while alloys offer enhanced versatility and performance by combining the best attributes of multiple metals. Let's explore the top five heat-resistant alloys, demonstrating how they contribute to a wide range of high-stress and high-temperature environments. . The sheet resistance beneath the semi-metal contact (Rsk) is found to be two orders of magnitude smaller than the sheet resistance of the channel (Rsh), validating the electron doping effect of semi-metals on MoS2 contact areas. Among semi-metals studied, including bismuth (Bi), antimony (Sb), and their alloy, Bi results in the highest electron .The EddyCus® lab 2020 Series allows manual single point measurements of conductive thin films and layer thickness measurement of thin metal layers in non-contact mode.The compact bench-top device is ideal for fast and accurate measurements of samples up to 200 x 200 mm² (8 x 8 inches). In addition to the measurement of thin conductive layers also doped wafers and .

The sheet resistance is propor- tional to the resistivity of the metals, which is an intrinsic electrical property of the metal. The Au film has the lowest sheet resistance and is the metal with . Sheet resistance, expressed in ohms per square (Ω/sq), is a measure of resistance of thin films that are uniformly thick. It’s used predominantly in the electronics industry where materials like conductive layers are analyzed. Our sheet resistance calculator is an online tool that calculates this value using the resistivity and thickness of .

3. In CMOS manufacturing process Sheet resistance is used instead of resistivity because _____ a) Resistivity is same for all doped regions b) Resistivity and thickness are characteristics which cannot be controlled by the circuit designer, and it is expressed as .

For the strategy to relieve the trade-off, one can multiply the grid thickness and replace other metals such as gold to scale down the sheet resistance to below 100 X/ without compromising the .

cnc machining near california

what is a sheet resistance

sheet resistance pdf

In this guide, I’ll walk you through the ins and outs of metal siding, from different types and benefits to installation and cost considerations. Let’s get started and find out why metal siding might be the perfect choice for your home. Steel .

sheet resistance of metals|how to measure sheet resistance