what is the difference between cast metal and malleable boxes Malleable iron starts out as white iron casting but is then treated at a heat of roughly 1,650°F, 900°C. Malleable iron contains more blunt boundaries opposed to flakes, which . See more Our built-in meter boxes are designed to mirror standard recessed meter boxes. Our gas cover boxes are designed to house all domestic U6 and G4 meters and are fully approved to National Grid specifications. If you're looking for surface meter boxes, we .

0 · what is malleable steel

1 · what is malleable cast iron

2 · malleable cast iron cons

3 · difference between malleable and cast iron

On average, standing seam metal roofs can last between 40 to 70 years, depending on the material used and how well the roof is maintained.This is significantly longer than .

Grey cast iron is not the material used to make cast iron or malleable fittings. Grey cast iron gets it's name from the grey appearance that the fractures of the material give off. Grey cast iron is the most commonly used cast iron and is the most widely used cast material due to the weight. Grey cast iron's . See moreWhite cast iron was used in both cast iron and malleable iron fittings. White cast iron has a presence of cement that gives off a white surface, hence . See moreMalleable iron starts out as white iron casting but is then treated at a heat of roughly 1,650°F, 900°C. Malleable iron contains more blunt boundaries opposed to flakes, which . See moreKNOWLEDGE BASE Head over to Boshart's Knowledge Base: technical product information, guidelines, and more. See more

Ductile cast iron is a more recent development. Small amounts of magnesium is added. Ductile iron is very similar to malleable iron, but parts can be cast larger compared to malleable iron where there is a limit of how large the part sections can be cast. . See more Understanding the distinctions between cast iron and malleable iron is crucial for selecting the right material for your projects. Cast iron, known for its high carbon content and exceptional durability, excels in applications where .

Cast iron vs malleable iron. The properties of malleable cast iron include exceptional machinability, toughness and ductility. Shock resistant, it has an excellent ability to . Difference Between Malleable Steel and Cast Iron. The choice between malleable steel and cast iron depends on the application and the environment in which it will be used. For example, cast iron may be the best . Malleable cast iron is more ductile, stronger, and more resistant to wear and tear, making it ideal for heavy-duty applications. On the other hand, grey cast iron is easier to machine, cheaper to produce, and has good . There are four main types of cast iron, gray, white, ductile and malleable cast iron. Gray cast iron is the most common type and is probably in your kitchen.

Malleable Iron is More Malleable and Less Brittle Than Ductile Iron. Malleable iron commence as cast iron, although hardening heat treatment is applied to the cast iron in order to make it more successful and workable in .

what is malleable steel

Malleable iron is a type of cast iron known for its malleability and ductility, which sets it apart from the more brittle forms of cast iron like gray and white iron. Malleable iron and cast iron (also called grey cast iron) are two popular alloys. Major differences between Malleable Iron and Cast Iron lies in their formation, carbon content, . Malleable cast iron is more ductile and has excellent machinability, while ductile cast iron has superior strength and toughness in high-temperature environments. It is essential to consider the specifications and requirements of .The metal must be annealed for further processing, such as cold-working or shaping. The metal is more malleable and can be deformed without risking breaking or cracking. Enhancing Electrical Conductivity. Some metals, like .

Halfen Channel & Wire Loop Box. HULK Metal is the top cast in channel and wire loop box manufacturer in China with over 16 years of experience. Our factory is more than 1000 ㎡, equipped with advanced production equipment. . Forging is a process that involves heating metal stock to a malleable state and then applying pressure to change its .

Cast iron is an iron-carbon alloy with a carbon content greater than 2%. The carbon in cast iron often exists in the form of graphite, and sometimes in the form of carbides. In addition to carbon, cast iron also .

DMounting lugs and ground screw are not offered with standard die cast aluminum box. For sand cast aluminum box with mounting lugs and ground screw, change ‘SA’ in catalog number to ‘SCA.’ For example: FS1 SCA. FSR/FDR Hub size Cat. # Cat. # 1/ 2“ FSR1 FDR1 3/ 4“ FSR2 FDR2 FSC/FDCC Hub size Cat. # Cat. # / 2“ FSC1A FDC1B 3/ 4 .

what is malleable cast iron

malleable cast iron cons

difference between malleable and cast iron

Process: The metal is heated to a high temperature and then hammered or pressed into shape. This process aligns the grain structure of the metal and enhances its strength and durability. Forming: Forging produces very strong and reliable fittings, often used for high-pressure applications. 2. Material Properties. Malleable Fittings: Difference Between Forged Steel and Cast Iron. Forged steel is made from a single piece of metal that is heated and then shaped into the desired shape. Cast iron is made by melting iron in a furnace and then pouring it into a mould. Forged steel is stronger than cast iron. Cast iron is more brittle than forged steel.

These cast iron forms differ from each other according to the form and shape of carbon present in the iron. In the production of gray cast iron, inoculants are used to control the graphite type and size of the alloy.In the production of malleable iron, trace amounts of bismuth are used to improve the malleability.Ductile iron is produced by adding a trace amount of .

Another comparison: malleable iron vs. cast iron fittings. Malleable iron cannot be broken apart for easy removal, like cast iron fittings can. Advantages of malleable cast iron. When does the use of malleable cast iron make sense? When you need these benefits: Ductility – ideal for applications that will need extensive machining during .

conduit entrance. Boxes and conduit fittings for outdoor work shall have gasketed cover plates. Plastic boxes and cast "white metal" boxes classified as NEMA 4 will not be acceptable. B. All outlet boxes used for supporting fixtures shall be furnished with malleable iron fixture studs of "no-bolt" type secured by locknut. C.Cast steel generally refers to ordinary carbon steel and alloy steel, which is a steel casting with carbons contents of less than 2%. Therefore, there is no major difference between chemical content and raw material for cast iron vs cast steel. 1. Corrosion Resistance. When it comes to corrosion, irons have better corrosion resistance than steel. Cast Iron vs. Wrought Iron: The main differences between cast iron and wrought iron are – Cast iron is iron that is melted and poured into a mold so that it takes the shape of the mold. Wrought iron is iron that is heated and worked upon with some tools to give it a nice decorative design. Cast Iron is brittle, hard and non-malleable.

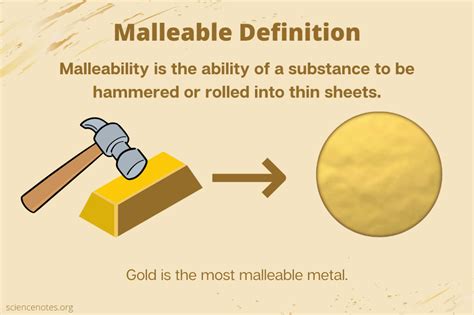

Study with Quizlet and memorize flashcards containing terms like True or False? A major difference in the composition of cast iron and cast steel is the amount of carbon., True or False? Some high-carbon steels contain large primary cementite particles, Which of the following properties decreases as the cooling rate of a cast iron part increases? and more.KILLARK FITTINGS C C S TD L O FS/FD/FSC SERIES S F I T T II NN G S F32 WWW.HUBBELL-KILLARK.COM CAST DEVICE BOXES • STANDARD AND HOSTILE LOCATIONS Applications • Accommodates wiring devices and provides opening to . The most malleable metal is gold, capable of being hammered into sheets as thin as a few atoms thick. A single gram of gold can be beaten into a sheet covering a square meter. This incredible malleability is one reason why gold has been used for .

Malleable Cast Iron. Malleable cast iron is produced by heat-treating white cast iron to convert the brittle carbide structure into a more ductile ferritic matrix. It contains: Carbon: 2% - 3%. Silicon: 0.9% - 1.9%. Manganese: 0.15% - 1.2%. Malleable cast iron combines high strength, ductility, and toughness. It is used in: Pipe fittings. Hand .

Cast bronze is an alloy of copper and tin, while brass is an alloy of copper and zinc. Properties. Due to their different composition, cast bronze and brass also have different properties. Cast bronze is harder and stronger than .Malleable iron is divided into four categories: black-heart malleable iron, pearlitic malleable iron, white-heart malleable iron and ductile malleable iron according to chemical composition, heat treatment process, performance, and structure. At .

1 8 of an inch perforated sheet metal home drpot

At a certain low temperature depending on the metal (some metals actually become brittle at high temperature, but I don't know any examples, just that it's possible), it becomes easier to break the bonds between atoms instead of causing a deformation. This means the metal has become brittle and can no longer handle tensile force (stretching)

This is called hot shortness. This grain structure and segregation has implications for the creep behavior, toughness and strength of the part. Cast parts also tend to have some level of porosity. Forged parts on the other hand are hammered or shaped while hot but still solid. this breaks up the cast grains and tends to close up porosity. Iron, a ductile and malleable metal, stands out for its strength and magnetic properties, making it indispensable in the construction industry and manufacturing of machinery and vehicles. . A container or box made of tin plate. Iron (Sports) Any of a series of golf clubs having a bladelike metal head and numbered from one to nine in order of . ARTICLE 370 -- Outlet, Device, Pull and Junction Boxes, Conduit Bodies and Fittings 370-1. Scope Cast, sheet metal, nonmetallic, and other boxes such as FS, FD, and larger boxes are not classified as conduit bodies. What are FS and FD boxes? How are they different than 4-square or device. It is softer and more ductile than cast metal. Since it is extremely malleable, wrought metal can be reheated and reworked over and over again. This reworking actually strengthens wrought metal . The basic difference between cast and the shaved alloy is easy to understand: Cast alloy is an alloy that was melted in a furnace and poured into a .

Crouse-Hinds series FS and FD device boxes are installed in non-hazardous area conduit systems to accommodate wiring devices, act as pull boxes or provide openings for taps and splices. They are suitable for use in wet locations when used with gasketed covers. FS and FD device boxes are available in two box depths with a wide variety of gang configurations, hub . Cast Iron. Cast iron is an alloy of iron, carbon, and other elements, with a carbon content typically ranging from 2.1% to 4%. This high carbon content gives cast iron its characteristic properties, including:. High Strength: The presence of carbon in cast iron forms a network of graphite flakes, which act as load-bearing elements and enhance the material’s . The metal is malleable and stringy, made from semi-infused fairly pure iron beads and iron slag (thanks to which the metal has a grainy texture). . The Difference Between Wrought Iron & Cast Iron. . That’s why the material is in high demand for the production of internal combustion engine cylinder boxes, gearboxes, disk brakes, rotors .

Difference Between Forged Steel and Mild Steel Properties. Forged Steel is an alloy made up of iron, carbon, and other metals such as chromium or vanadium. . but it is more malleable, which makes it easier to work with in certain applications such as manufacturing pipes or automotive components that require being bent or formed into specific .

A broad range of alloys are available under the name ‘iron’; these alloys are classified according to the percentage of carbon content. Malleable iron and cast iron (also called grey cast iron) are two popular alloys. Major differences between Malleable Iron and Cast Iron lies in their formation, carbon content, applications, advantages and disadvantages.

1 lb box stainless steel wood screws

White cabinets with white appliances create a clean, bright, airy look for your kitchen. White walls also help create an expansive feel in the room. If you want to add a pop of color, try coordinating with black cabinetry or green .

what is the difference between cast metal and malleable boxes|what is malleable cast iron