cnc machine origin The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to . The Square D by Schneider Electric 200 amp ringless underground meter socket is ansi certified and csa- and ul listed. This meter socket is intended for surface mounting and features a ringless design with a horn bypass and 4 jaws.

0 · who invented cnc machine

1 · when were cnc machines invented

2 · when did cnc machining start

3 · history of cnc machine pdf

4 · evolution of cnc machines

5 · cnc machine history timeline

6 · cnc machine background

7 · cnc computer numerical control machines

Screed metallic trunkings are a quick and easy way to install power and data distribution throughout screed floors. These systems are particularly robust and are designed to support superior loads. Junction boxes and risers allow easy access when installing cables or .

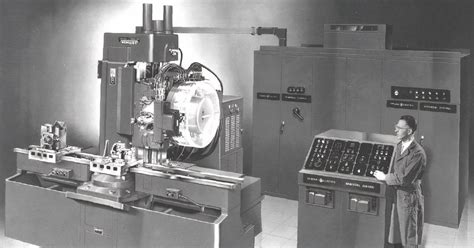

John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. The first NC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the controls to follow points fed into the system on punched tape. .The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to . When was the first CNC machine patented? The first CNC machine was patented in 1958 by Richard Kegg, in collaboration with MIT. This groundbreaking invention, a numerically controlled milling machine, .

CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots . In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as .

Here, we look at four essentials: early machine tools, punched cards, servomechanisms, and the Automatically Programmed Tool (APT) programming language. First, a shout out to what is widely. Studies on numerical control started after the Second World War through funding from the U.S. Air Force. The military organization paid a team led by John Parsons to create a mathematical method to operate machine tools. .

large green electrical box

The machine origin in CNC (Computer Numerical Control) plays a vital role in the precision and accuracy of machining operations. Over the years, the origin setting has evolved, moving from . This section will introduce you to CNC machining history, the first CNC machine, and its evolution over time. The First CNC Machine The first CNC machine was credited to James Parsons in 1949. John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.

The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to automate machine tool operations using electronic controls. When was the first CNC machine patented? The first CNC machine was patented in 1958 by Richard Kegg, in collaboration with MIT. This groundbreaking invention, a numerically controlled milling machine, represented the transition from manually operated machine tools to automated CNC systems.CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future. In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as computer numerical control (CNC).

Here, we look at four essentials: early machine tools, punched cards, servomechanisms, and the Automatically Programmed Tool (APT) programming language. First, a shout out to what is widely.

Studies on numerical control started after the Second World War through funding from the U.S. Air Force. The military organization paid a team led by John Parsons to create a mathematical method to operate machine tools. Parsons’s research eventually led to a punch-tape NC machine.

The machine origin in CNC (Computer Numerical Control) plays a vital role in the precision and accuracy of machining operations. Over the years, the origin setting has evolved, moving from manual methods to automated processes. This section will introduce you to CNC machining history, the first CNC machine, and its evolution over time. The First CNC Machine The first CNC machine was credited to James Parsons in 1949. John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.

The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to automate machine tool operations using electronic controls.

When was the first CNC machine patented? The first CNC machine was patented in 1958 by Richard Kegg, in collaboration with MIT. This groundbreaking invention, a numerically controlled milling machine, represented the transition from manually operated machine tools to automated CNC systems.CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future. In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as computer numerical control (CNC).

Here, we look at four essentials: early machine tools, punched cards, servomechanisms, and the Automatically Programmed Tool (APT) programming language. First, a shout out to what is widely.

Studies on numerical control started after the Second World War through funding from the U.S. Air Force. The military organization paid a team led by John Parsons to create a mathematical method to operate machine tools. Parsons’s research eventually led to a punch-tape NC machine.

who invented cnc machine

Definition and Key Characteristics: Ultra-precision machining refers to manufacturing parts with tolerances in the range of micrometers or even nanometers. Key characteristics include extreme precision, high-quality surface finishes, and the ability to machine complex geometries.

cnc machine origin|cnc computer numerical control machines