cnc drill grinding machine WALTER provides cutting edge technology to the tool grinding machine market with an extensive product line that includes the HELITRONIC VISION tool grinder (featuring linear/torque motors in all axes) and HELITRONIC POWER .

Buy U-Bracket with M8 Thread, 1-1/2" x 1-1/2" x 1-1/2" Wood Technology 4060.001.098 & more Table Assembly Hardware at Woodworker .

0 · micromatic cylindrical grinding machine

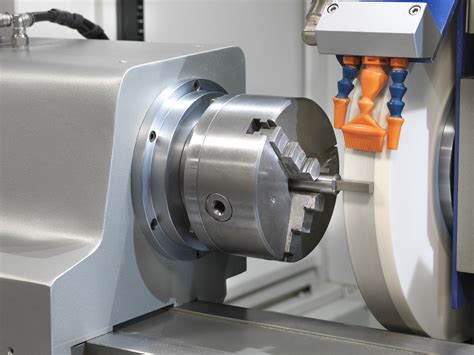

1 · external cylindrical grinding machine

2 · cylindrical grinding machine manufacturers

3 · cnc internal grinding machine

4 · cnc grinding machine specifications

5 · cnc grinding machine manufacturers

6 · cnc end mill grinding machine

7 · cnc cylindrical grinding machine price

Sigma Engineered Solutions 14250WH Metal Electrical Outlet Box, Weatherproof, Easy Mount Plug and Receptacle Protector, White, (3) 1/2-Inch Holes, 1 Gang Box

Drilling machines or CNC drills are used to make cylindrical holes, both through and blind holes, using suitable sizes of drill bits. Among the different types of CNC machines, they . The XPS-16+ Automatic 4-axis CNC Drill Sharpener and Grinder is an extremely accurate work horse for high tech applications. The XPS-16+ is for shops that demand the .

The fully automated 5-axis CNC drill grinding centers from Avyac, world market leaders in the field of deep hole grinding, guarantee maximum precision and economy. Trust in the outstanding technology of the industry leader.Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. With the HELITRONIC MINI PLUS tool grinding machine, tools with small and medium diameters can .

Today’s capital equipment must be more flexible and capable than ever. With this in mind, Makino has introduced the 5 Axis CNC grinder (G5), capable of grinding, milling, drilling and tapping, .WALTER provides cutting edge technology to the tool grinding machine market with an extensive product line that includes the HELITRONIC VISION tool grinder (featuring linear/torque motors in all axes) and HELITRONIC POWER .

All Weldon CNC grinders can routinely and automatically grind contours, tapers, chamfers, fillets, radii, shoulders, and straight diameters in one setup and one continuous operation. They have the capabilities for OD/ID work in one setup; .Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. What is tool grinding? Tool grinding is a subset of the .

We custom-build every machine with personalized software and hardware so you have the exact machine you need to grind your tools with confidence and accuracy. MCT has been supplying our customers with customized CNC .

Drilling machines or CNC drills are used to make cylindrical holes, both through and blind holes, using suitable sizes of drill bits. Among the different types of CNC machines, they specialize in drilling, reaming, boring, and internal threading tasks. The XPS-16+ Automatic 4-axis CNC Drill Sharpener and Grinder is an extremely accurate work horse for high tech applications. The XPS-16+ is for shops that demand the ultimate in precision, simplicity and productivity.The fully automated 5-axis CNC drill grinding centers from Avyac, world market leaders in the field of deep hole grinding, guarantee maximum precision and economy. Trust in the outstanding technology of the industry leader.Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. With the HELITRONIC MINI PLUS tool grinding machine, tools with small and medium diameters can be flexibly produced and resharpened.

A CNC grinding machine, or CNC grinder, operates automatically with minimum intervention from a machinist or operator. It follows programmed instructions to produce smooth surface finishes while reducing distortion and increasing the grinding process’s efficiency.

charcoal gray metal roof on white house red shutters

micromatic cylindrical grinding machine

Today’s capital equipment must be more flexible and capable than ever. With this in mind, Makino has introduced the 5 Axis CNC grinder (G5), capable of grinding, milling, drilling and tapping, all on the same machine. cnc grinding machines , cnc grinding machineWALTER provides cutting edge technology to the tool grinding machine market with an extensive product line that includes the HELITRONIC VISION tool grinder (featuring linear/torque motors in all axes) and HELITRONIC POWER universal CNC tool grinders.

All Weldon CNC grinders can routinely and automatically grind contours, tapers, chamfers, fillets, radii, shoulders, and straight diameters in one setup and one continuous operation. They have the capabilities for OD/ID work in one setup; ID contouring; and nonround grinding. all with excellent results in productivity and quality.Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. What is tool grinding? Tool grinding is a subset of the larger field of grinding. It involves a machining-based production process using abrasives or grinding wheels to produce or re-sharpen a workpiece.We custom-build every machine with personalized software and hardware so you have the exact machine you need to grind your tools with confidence and accuracy. MCT has been supplying our customers with customized CNC machines for over 32 years with outstanding support history.

Drilling machines or CNC drills are used to make cylindrical holes, both through and blind holes, using suitable sizes of drill bits. Among the different types of CNC machines, they specialize in drilling, reaming, boring, and internal threading tasks.

The XPS-16+ Automatic 4-axis CNC Drill Sharpener and Grinder is an extremely accurate work horse for high tech applications. The XPS-16+ is for shops that demand the ultimate in precision, simplicity and productivity.The fully automated 5-axis CNC drill grinding centers from Avyac, world market leaders in the field of deep hole grinding, guarantee maximum precision and economy. Trust in the outstanding technology of the industry leader.Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. With the HELITRONIC MINI PLUS tool grinding machine, tools with small and medium diameters can be flexibly produced and resharpened.

A CNC grinding machine, or CNC grinder, operates automatically with minimum intervention from a machinist or operator. It follows programmed instructions to produce smooth surface finishes while reducing distortion and increasing the grinding process’s efficiency.Today’s capital equipment must be more flexible and capable than ever. With this in mind, Makino has introduced the 5 Axis CNC grinder (G5), capable of grinding, milling, drilling and tapping, all on the same machine. cnc grinding machines , cnc grinding machine

WALTER provides cutting edge technology to the tool grinding machine market with an extensive product line that includes the HELITRONIC VISION tool grinder (featuring linear/torque motors in all axes) and HELITRONIC POWER universal CNC tool grinders.

All Weldon CNC grinders can routinely and automatically grind contours, tapers, chamfers, fillets, radii, shoulders, and straight diameters in one setup and one continuous operation. They have the capabilities for OD/ID work in one setup; ID contouring; and nonround grinding. all with excellent results in productivity and quality.Our CNC grinding machines are world-class tool grinders for production and re-sharpening, from entry-level model to high-end solution. What is tool grinding? Tool grinding is a subset of the larger field of grinding. It involves a machining-based production process using abrasives or grinding wheels to produce or re-sharpen a workpiece.

external cylindrical grinding machine

charcoal companion stainless steel v-shaped smoker box

At Toolstation, we stock a range of electrical enclosures from trusted brands like .

cnc drill grinding machine|cnc internal grinding machine