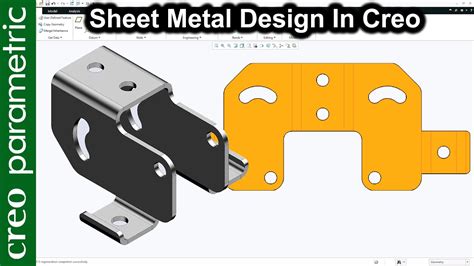

creo parametric sheet metal tutorial Learn how to use Creo Parametric 10.0 to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts. Wolfsburg West is your ultimate source for Volkswagen Beetle and Volkswagen Bus restoration parts. With more than a quarter century of high quality service, our comprehensive inventory now exceeds 5000 parts, making us one of the largest "stock" Volkswagen parts dealers in the world.

0 · sheet metal in creo parametric

1 · flat vs flange in creo

2 · creo sheet metal tutorial pdf

3 · creo sheet metal practice drawing

4 · creo sheet metal drawing

5 · creo sheet metal design

6 · creo practice sheet metal models

7 · creo 8 sheet metal

The WAGO Junction Box helps you connect up to 60 conductors with WAGO’s 221 Series Splicing Connector for all conductor types with cross-sections up to 4 mm 2 (12 AWG). Gelbox – Moisture Protection for WAGO Splicing Connectors

PTC Creo Parametric 9.0 Basic Sheet Metal Tutorial For Beginner. This tutorial is designed for beginners who have basic knowledge of PTC Creo Parametric 9.0.. sheet metal in creo- tutorial 1planer command in creo parametricEvery sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the .Learn how to use Creo Parametric 10.0 to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.

sheet metal in creo parametric

flat vs flange in creo

The Creo Parametric 8.0: Sheet Metal Design training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and . A step-by-step guide on how to create the chair from single sheet plate using creo or pro e software inside sheet metal module. In this tutorial, we will learn about the basic techniques related to ‘Sheet Metal’ functionality of ‘Creo Parametric’ by modelling a Cover. In the creation .

Explore the fundamentals of sheet metal creation in Top-Down Assembly mode using the shell technique in this 29-minute tutorial for Creo Parametric 9.0. Learn how to effectively utilize the .

In this tutorial, you can learn How to use Sheet Metal Conversion modelling technique in ProE or with same logic in Creo Parametric. In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange wall. PTC Creo Parametric 9.0 Basic Sheet Metal Tutorial For Beginner. This tutorial is designed for beginners who have basic knowledge of PTC Creo Parametric 9.0..

video distribution box

creo sheet metal tutorial pdf

vhf cnc milling machine

sheet metal in creo- tutorial 1planer command in creo parametricEvery sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the exact contours of the new basic sheet.Learn how to use Creo Parametric 10.0 to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.The Creo Parametric 8.0: Sheet Metal Design training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features.

A step-by-step guide on how to create the chair from single sheet plate using creo or pro e software inside sheet metal module.

In this tutorial, we will learn about the basic techniques related to ‘Sheet Metal’ functionality of ‘Creo Parametric’ by modelling a Cover. In the creation .Explore the fundamentals of sheet metal creation in Top-Down Assembly mode using the shell technique in this 29-minute tutorial for Creo Parametric 9.0. Learn how to effectively utilize the shell technique to design sheet metal components within an assembly environment. In this tutorial, you can learn How to use Sheet Metal Conversion modelling technique in ProE or with same logic in Creo Parametric.

In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange wall. PTC Creo Parametric 9.0 Basic Sheet Metal Tutorial For Beginner. This tutorial is designed for beginners who have basic knowledge of PTC Creo Parametric 9.0.. sheet metal in creo- tutorial 1planer command in creo parametric

creo sheet metal practice drawing

Every sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the exact contours of the new basic sheet.

Learn how to use Creo Parametric 10.0 to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.

The Creo Parametric 8.0: Sheet Metal Design training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features.

A step-by-step guide on how to create the chair from single sheet plate using creo or pro e software inside sheet metal module. In this tutorial, we will learn about the basic techniques related to ‘Sheet Metal’ functionality of ‘Creo Parametric’ by modelling a Cover. In the creation .Explore the fundamentals of sheet metal creation in Top-Down Assembly mode using the shell technique in this 29-minute tutorial for Creo Parametric 9.0. Learn how to effectively utilize the shell technique to design sheet metal components within an assembly environment.

veta precision sheet metal manufacturing

VW T4 Exhaust Heritage Parts Centre have a selection of exhaust parts to fit your classic T4 Transporter - exhaust sections - silencers, T4 van down pipes, performance headers, T4 bus exhaust fittings, exhaust kits.

creo parametric sheet metal tutorial|flat vs flange in creo