carvewright cnc machine instal sandparer Check that the sliding plate is slid over against the edge of the board. Verify that the correct bit is inserted and correctly assembled. Check hole in the board sensor. Check for a hole on the . Study with Quizlet and memorize flashcards containing terms like Who is born at the start of the film, How does Amelie's mother die, What does Amelie find hidden inside her wall? and more.

0 · carvewright sandpaper belt repair

1 · carvewright rubber belt replacement

A distribution from a nonqualified annuity is not permitted to be rolled over. Any amount in box 2a is subject to tax and to an early-distribution penalty. If the distribution was actually from an IRA annuity, contact the payer to obtain a corrected Form 1099-R.

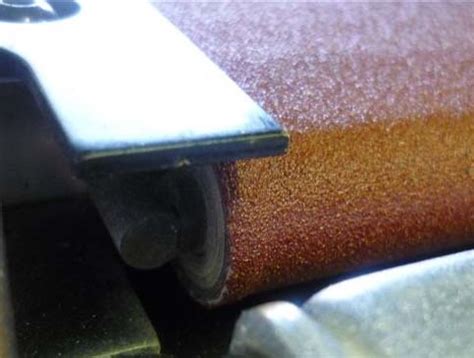

Assemble the new sandpaper belt. Slide the new belt over the tray from the end opposite the drive gear. The belt needs to be placed between the two belt keepers as shown in Figure 7. .

Replacing the sandpaper belts or upgrading to the Heavy Duty rubber belts is easy to do with these steps. DOWNLOADABLE PDF INSTRUCTIONS. Installation of Heavy Duty .The errors appear when the rolled-up sandpaper belts lift the workpiece off of the board tracking sensor that tracks the position of the board. It is [.] Read More → There are 2 options for doing repairs and upgrades to your CarveWright CNC machine. The first is to do the repairs yourself with the guidance of documents and videos available on the CarveWright support .Check that the sliding plate is slid over against the edge of the board. Verify that the correct bit is inserted and correctly assembled. Check hole in the board sensor. Check for a hole on the .

Anyone know of a good source that sells custom sized sandpaper belts? I got a traction belt for my Performax from Industrial Abrasives. Yes they will make custom belts. You .Sanding mops are a quick and easy way to sand and prepare your carvings for paint or stain. The mop turns as its frayed sandpaper edges polish your project. The Sanding Mop does not .

In order to assist in the learning curve of the CarveWright System, we have compiled our tutorial information into a linear learning guide. This guide will start at the .Next, you will install your Designer software, create your own Customer Account and register your machine, software licenses and computers. Make sure to follow the steps in the Designer .

Load your material into the machine, install the requested bit, and away it goes. 4. FINISH AND SELL. Finish your project and sell it, share it, or keep it for yourself. The intuitive and easy-to-use Designer software package is included with .

Assemble the new sandpaper belt. Slide the new belt over the tray from the end opposite the drive gear. The belt needs to be placed between the two belt keepers as shown in Figure 7. Remove the retaining pins from the slide rods by applying a small amount of force to the tensioning roller and pulling them out or by reinserting the tray into the . Replacing the sandpaper belts or upgrading to the Heavy Duty rubber belts is easy to do with these steps. DOWNLOADABLE PDF INSTRUCTIONS. Installation of Heavy Duty Traction Belts. Or Watch This Video. Tagged: rubber belts. Sandpaper belts Traction belts.The errors appear when the rolled-up sandpaper belts lift the workpiece off of the board tracking sensor that tracks the position of the board. It is [.] Read More →

There are 2 options for doing repairs and upgrades to your CarveWright CNC machine. The first is to do the repairs yourself with the guidance of documents and videos available on the CarveWright support website.Check that the sliding plate is slid over against the edge of the board. Verify that the correct bit is inserted and correctly assembled. Check hole in the board sensor. Check for a hole on the board tracking sensor - Look on the plastic bar of the board tracking sensor for hole. If there is a hole, place a dime on top of that and run the machine. Anyone know of a good source that sells custom sized sandpaper belts? I got a traction belt for my Performax from Industrial Abrasives. Yes they will make custom belts. You just have to know the size. Here's a quote from their web site.Sanding mops are a quick and easy way to sand and prepare your carvings for paint or stain. The mop turns as its frayed sandpaper edges polish your project. The Sanding Mop does not attach to the machine.

In order to assist in the learning curve of the CarveWright System, we have compiled our tutorial information into a linear learning guide. This guide will start at the beginning, teaching you how to use the system, and progress into more advanced features, accessories, and .Next, you will install your Designer software, create your own Customer Account and register your machine, software licenses and computers. Make sure to follow the steps in the Designer Software Quick Start Guide located in your box and on our website. These steps need to be accomplished before proceeding with this learning guide.Load your material into the machine, install the requested bit, and away it goes. 4. FINISH AND SELL. Finish your project and sell it, share it, or keep it for yourself. The intuitive and easy-to-use Designer software package is included with every RAVEN CNC Router.Assemble the new sandpaper belt. Slide the new belt over the tray from the end opposite the drive gear. The belt needs to be placed between the two belt keepers as shown in Figure 7. Remove the retaining pins from the slide rods by applying a small amount of force to the tensioning roller and pulling them out or by reinserting the tray into the .

Replacing the sandpaper belts or upgrading to the Heavy Duty rubber belts is easy to do with these steps. DOWNLOADABLE PDF INSTRUCTIONS. Installation of Heavy Duty Traction Belts. Or Watch This Video. Tagged: rubber belts. Sandpaper belts Traction belts.The errors appear when the rolled-up sandpaper belts lift the workpiece off of the board tracking sensor that tracks the position of the board. It is [.] Read More →

There are 2 options for doing repairs and upgrades to your CarveWright CNC machine. The first is to do the repairs yourself with the guidance of documents and videos available on the CarveWright support website.Check that the sliding plate is slid over against the edge of the board. Verify that the correct bit is inserted and correctly assembled. Check hole in the board sensor. Check for a hole on the board tracking sensor - Look on the plastic bar of the board tracking sensor for hole. If there is a hole, place a dime on top of that and run the machine. Anyone know of a good source that sells custom sized sandpaper belts? I got a traction belt for my Performax from Industrial Abrasives. Yes they will make custom belts. You just have to know the size. Here's a quote from their web site.Sanding mops are a quick and easy way to sand and prepare your carvings for paint or stain. The mop turns as its frayed sandpaper edges polish your project. The Sanding Mop does not attach to the machine.

In order to assist in the learning curve of the CarveWright System, we have compiled our tutorial information into a linear learning guide. This guide will start at the beginning, teaching you how to use the system, and progress into more advanced features, accessories, and .

carvewright sandpaper belt repair

Next, you will install your Designer software, create your own Customer Account and register your machine, software licenses and computers. Make sure to follow the steps in the Designer Software Quick Start Guide located in your box and on our website. These steps need to be accomplished before proceeding with this learning guide.

enclosure plastic electrical

If you hit a power pole, pad-mounted transformer (“green box”) or other electrical equipment, DO NOT get out of the vehicle or cab. Instead, call 9-1-1 and wait for utility crews to come and de-energize power.

carvewright cnc machine instal sandparer|carvewright sandpaper belt repair