5 axis cnc machine diagram In this blog post, we have explored the intricacies of a 5-axis CNC machine through a comprehensive diagram and guide. By understanding the functionality, applications, . A junction box provides protection for these sensitive connections against bad weather, accidental contact, tampering and other hazards that can damage wiring. Below, we’ll talk about how to size a junction box appropriately and determine which attributes your junction box needs to have.

0 · mvmc meaning machine 5 axis

1 · 5 axis machining explained

2 · 5 axis cnc programming pdf

3 · 5 axis cnc program example

4 · 5 axis cnc machining part

5 · 5 axis cnc machine specifications

6 · 5 axis cnc machine programming

7 · 5 axis cnc explained

Standard North American junction boxes come in a variety of shapes and sizes (round, octagon, square, rectangular); however, most wiring devices intended for junction box mounting, save for light fixtures, are designed around the standard device yoke mounting pattern -- this is defined in NEMA WD-6 (an abridged version can be found here) as a 4 .

mvmc meaning machine 5 axis

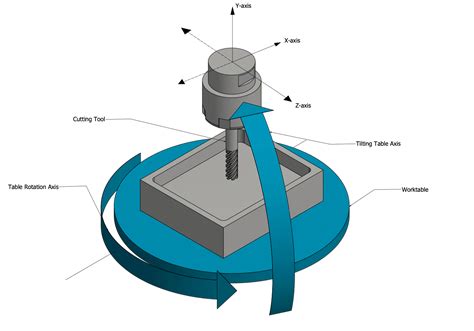

In this blog post, we have explored the intricacies of a 5-axis CNC machine through a comprehensive diagram and guide. By understanding the functionality, applications, .The diagram above illustrates the primary components and axes of a 5-axis CNC machine: 1. X-Axis: Represents the machine's horizontal plane of movement (left-right).

Discover the different components and functionality of a 5 axis CNC machine through a detailed diagram. Learn about the axis system, cutting tools, control panel, and .

sterilite 30 gallon tote box steel case of 6

5-Axis CNC Machining. As well as left–right, front–back, and up–down, a 5-axis CNC machine has two more movements up its sleeve: it can also rotate its tool around the other two axes (A and B). You can see how the . A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it .Modern machine tools, including the increasingly popular 5-axis machining center, place exacting demands on the CNC for exceptional speed, precision, and reliability. The CNC holds a large .5-axis machining is a specific type of CNC machining that enhances the traditional 3-axis approach. This electromechanical process controls tools across five axes with high accuracy and precision to cut away excess material and .

What is 5-axis CNC Machining? In the simplest terms, 5-axis machining involves using a CNC to move a part or cutting tool along five different axes simultaneously. This enables the machining of very complex parts, which . Discover the different components and functionality of a 5 axis CNC machine through a detailed diagram. Learn about the axis system, cutting tools, control panel, and safety features.

The diagram above illustrates the primary components and axes of a 5-axis CNC machine: 1. X-Axis: Represents the machine's horizontal plane of movement (left-right).With multi-axis machining, the main objectives are to achieve perfect surface quality, precision, and speed without any need for remachining. Within this context, workflow is typically character-ized by the CAD-CAM-CNC process chain.

5-axis CNC machining leverages advanced computer numerical control (CNC) technology to orchestrate precise, simultaneous movements along five distinct axes. This sophisticated control system enables the machining of complex geometries with unprecedented flexibility and efficiency. A typical 5-axis CNC machine diagram shows the machine’s components, including the spindle, rotary tables, and the various axes. Understanding the diagram helps you understand how each part contributes to the overall machining process and maintenance requirements. 5-Axis CNC Machines. A 5-axis CNC machine has a CNC machine axis count of 5. This number includes the three main linear axes (X, Y, and Z) and any two rotary axes. This means that a 5-axis CNC machine includes the X, Y, and Z linear axes, along with two of the following rotational axes: A, B, or C.Five axis CNC machining refers to the ability of the CNC machine to perform movement about five different axis simultaneously. Most CNC manufacturers define their machines movement starting with the three primary axis, X. Y and Z, with the Z axis being parallel to .

5-axis machining is a specific type of CNC machining that enhances the traditional 3-axis approach. This electromechanical process controls tools across five axes with high accuracy and precision to cut away excess material and produce components and parts. A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it ideal for producing intricate and complex geometries with exceptional precision.

In the simplest terms, 5-axis machining involves using a CNC to move a part or cutting tool along five different axes simultaneously. This enables the machining of very complex parts, which is why 5-axis is especially popular for aerospace applications.

Discover the different components and functionality of a 5 axis CNC machine through a detailed diagram. Learn about the axis system, cutting tools, control panel, and safety features.

The diagram above illustrates the primary components and axes of a 5-axis CNC machine: 1. X-Axis: Represents the machine's horizontal plane of movement (left-right).With multi-axis machining, the main objectives are to achieve perfect surface quality, precision, and speed without any need for remachining. Within this context, workflow is typically character-ized by the CAD-CAM-CNC process chain. 5-axis CNC machining leverages advanced computer numerical control (CNC) technology to orchestrate precise, simultaneous movements along five distinct axes. This sophisticated control system enables the machining of complex geometries with unprecedented flexibility and efficiency. A typical 5-axis CNC machine diagram shows the machine’s components, including the spindle, rotary tables, and the various axes. Understanding the diagram helps you understand how each part contributes to the overall machining process and maintenance requirements.

5-Axis CNC Machines. A 5-axis CNC machine has a CNC machine axis count of 5. This number includes the three main linear axes (X, Y, and Z) and any two rotary axes. This means that a 5-axis CNC machine includes the X, Y, and Z linear axes, along with two of the following rotational axes: A, B, or C.Five axis CNC machining refers to the ability of the CNC machine to perform movement about five different axis simultaneously. Most CNC manufacturers define their machines movement starting with the three primary axis, X. Y and Z, with the Z axis being parallel to .5-axis machining is a specific type of CNC machining that enhances the traditional 3-axis approach. This electromechanical process controls tools across five axes with high accuracy and precision to cut away excess material and produce components and parts.

A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it ideal for producing intricate and complex geometries with exceptional precision.

steel workshop cabinets

Exploring the Allure of Mens Cologne in Yellow Metal Boxes In the world of men's fragrances, the yellow metal box has become a symbol of sophistication and exclusivity. These captivating containers house some of the most sought-after mens cologne scents, each with a unique story and allure.

5 axis cnc machine diagram|5 axis cnc program example