cnc machine milling compoennts With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing .

What is solar panel junction box? A solar panel junction box is an essential component of a solar panel system, which serves as an enclosure for electrical connections and protection for the solar cells. It is typically located at .

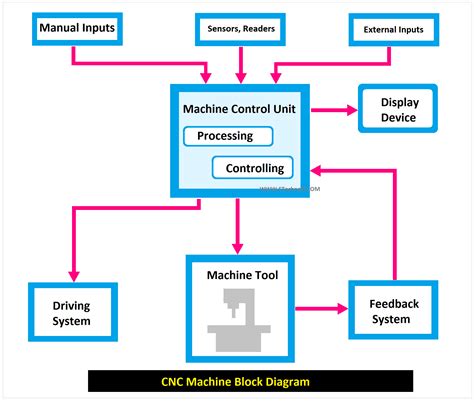

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · milling machine diagram labelled

3 · cnc milling machine parts names

4 · cnc milling machine diagram

5 · cnc mill parts diagram

6 · cnc machine components list

7 · block diagram of cnc machine

The junction box can be located at any height above the pool as the lights are 12 volts. Potting compound needs to be applied to the cord end in the junction box as well as the .

CNC milling is a subtractive manufacturing process where material is removed from a solid block to create parts. That being said, there are basic components in every CNC mill that allow it to function as intended. I’ve .

Because of the different shapes and mechanical application methods of the milling cutters, the milling machine can perform various milling jobs, including plane milling, surface milling, angular milling, groove milling, . CNC milling machines are equipped with several essential parts that work in unity to facilitate the machining process. These machines use computer numerical control (CNC) and automated features to control the . CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or .

CNC lathes are specifically well-suited for manipulating cylindrical parts, while mills can be utilized for flat, curved, or angular components. CNC machines consist of several key components and elements that contribute to their .

With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing . Discover the key components of a CNC milling machine such as the CCU, drive motors, spindle motor, and more. Learn how these parts work together for precision manufacturing.What are the Parts of a CNC Machine? Bed: Typically constructed from cast iron for enhanced durability and strength, the bed is the machine’s foundation, supporting all components. Spindle: Inside the machining area, the electrically .

Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of horizontal milling machines. CNC milling is a subtractive manufacturing process where material is removed from a solid block to create parts. That being said, there are basic components in every CNC mill that allow it to function as intended. I’ve created a list of the standard and most common CNC milling machine parts that you need to know about.

Because of the different shapes and mechanical application methods of the milling cutters, the milling machine can perform various milling jobs, including plane milling, surface milling, angular milling, groove milling, gear milling, and cam milling.

There are various components of the general CNC milling machine. Let’s see them one by one. 01. Column. The column in case of the CNC Machine is to provide the support and structure to the other machine components. Column acts as a support structure for the milling machine. 02. Machine interface. CNC milling machines are equipped with several essential parts that work in unity to facilitate the machining process. These machines use computer numerical control (CNC) and automated features to control the cutting tool and workpiece movement, creating unique and precise-looking machined parts. CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts. This .CNC lathes are specifically well-suited for manipulating cylindrical parts, while mills can be utilized for flat, curved, or angular components. CNC machines consist of several key components and elements that contribute to their functionality and efficiency. Here, we will explore the primary parts of CNC machines and the elements they incorporate.

With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders.

schematic diagram of cnc machine

Discover the key components of a CNC milling machine such as the CCU, drive motors, spindle motor, and more. Learn how these parts work together for precision manufacturing.

What are the Parts of a CNC Machine? Bed: Typically constructed from cast iron for enhanced durability and strength, the bed is the machine’s foundation, supporting all components. Spindle: Inside the machining area, the electrically driven spindle . Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of horizontal milling machines. CNC milling is a subtractive manufacturing process where material is removed from a solid block to create parts. That being said, there are basic components in every CNC mill that allow it to function as intended. I’ve created a list of the standard and most common CNC milling machine parts that you need to know about.

Because of the different shapes and mechanical application methods of the milling cutters, the milling machine can perform various milling jobs, including plane milling, surface milling, angular milling, groove milling, gear milling, and cam milling.

There are various components of the general CNC milling machine. Let’s see them one by one. 01. Column. The column in case of the CNC Machine is to provide the support and structure to the other machine components. Column acts as a support structure for the milling machine. 02. Machine interface. CNC milling machines are equipped with several essential parts that work in unity to facilitate the machining process. These machines use computer numerical control (CNC) and automated features to control the cutting tool and workpiece movement, creating unique and precise-looking machined parts. CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts. This .CNC lathes are specifically well-suited for manipulating cylindrical parts, while mills can be utilized for flat, curved, or angular components. CNC machines consist of several key components and elements that contribute to their functionality and efficiency. Here, we will explore the primary parts of CNC machines and the elements they incorporate.

With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders. Discover the key components of a CNC milling machine such as the CCU, drive motors, spindle motor, and more. Learn how these parts work together for precision manufacturing.

parts made by cnc machine

Hot glue is a great option because it fuses into the weave and fibers of the fabric to create a strong bond. Can you use hot glue on fabric and wash it? Yes, hot glue should last for quite a while on the fabric, and it’s waterproof!

cnc machine milling compoennts|cnc milling machine diagram