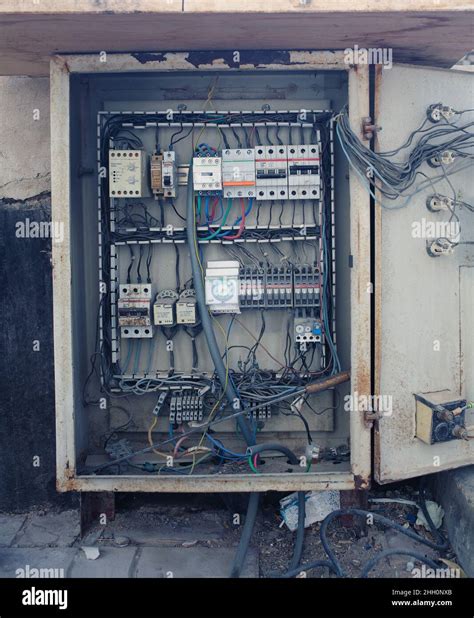

electrical box too corroded A panel cabinet that has only minor corrosion should be evaluated to determine the cause of the corroded area, and then repaired, to keep the rust from advancing further. Rain leakage coming down a service mast, for example, can ruin a panel box and circuit breakers if not repaired promptly. Before you head off to get your materials, here are some of the different types of sheet metal and their advantages and disadvantages. Alloy steel, as the name implies, mixes various components to provide a customisable set of characteristics. Carbon steel serves as this material's primary element. Other components are included, such as:

0 · when to replace electrical panel box

1 · old electrical panel boxes

2 · electrical panel replacement problems

3 · electrical panel corrosion problems

4 · electrical panel cabinet corrosion

5 · electrical panel box repair

6 · electrical panel box lifespan

7 · damaged electrical panels

Thicker sheets are not ideal for hemming as they are more prone to cracking when bent during the process. This article is about the sheet metal basics, specifically sheet metal hemming, its types, techniques, applications, and its benefits in sheet metal fabrication.

Corrosion is not good between electrical contacts, where breaker contacts the bus bar. It causes increase in resistance, causing extra heat. Are . A panel cabinet that has only minor corrosion should be evaluated to determine the cause of the corroded area, and then repaired, to keep the rust from advancing further. Rain leakage coming down a service mast, for example, can ruin a panel box and circuit breakers if not repaired promptly. Corrosion at interior components of an electrical panel creates several safety problems: 1) Circuit breakers are mechanical devices and, like any mechanical device, corrosion can cause it to freeze up and not trip when too much current is flowing in the circuit. Even if your electrical panel isn’t near a water source, remember that humidity can cause corrosion. When it comes to your electrical panel, always err on the side of being overly cautious. An experienced electrician can tell .

Troubleshooting Tip – Regularly inspect your breaker box for signs of rust, corrosion, or deterioration, such as discolored or charred components. If you notice any damage, contact a licensed electrician immediately for repairs . Corrosion is not good between electrical contacts, where breaker contacts the bus bar. It causes increase in resistance, causing extra heat. Are you near salt water or smelly industrial plant? –

A panel cabinet that has only minor corrosion should be evaluated to determine the cause of the corroded area, and then repaired, to keep the rust from advancing further. Rain leakage coming down a service mast, for example, can ruin a panel box and circuit breakers if not repaired promptly.If you hear noises coming from your panel, your breaker box could be arching or vibrating caused by loose connections within the panel. This is a bad sign. If you see signs of corrosion in the electrical box. Corrosion happens over time when moisture is introduced within the panel. Corrosion at interior components of an electrical panel creates several safety problems: 1) Circuit breakers are mechanical devices and, like any mechanical device, corrosion can cause it to freeze up and not trip when too much current is flowing in the circuit. Various things can cause damage to an electrical box, ranging from improper installation to corrosion. It could be a hairline crack on the top along a corner or a giant gaping hole created by rust deteriorating the box’s metal.

Even if your electrical panel isn’t near a water source, remember that humidity can cause corrosion. When it comes to your electrical panel, always err on the side of being overly cautious. An experienced electrician can tell you whether your panel has safety issues. Troubleshooting Tip – Regularly inspect your breaker box for signs of rust, corrosion, or deterioration, such as discolored or charred components. If you notice any damage, contact a licensed electrician immediately for repairs or replacement. The sheathing on one of the ground wires appears to be melted. A faulty appliance plugged into the outlet could have overheated the outlet if the circuit breakers (or fuses) weren't working properly. The corroded look on the wires could also have been caused by . When electrical wires are left alone too long in the elements, the metal in the wires can corrode. Electrical wires are usually made from copper and, as such, prone to oxidation. If connected to a battery, the subsequent corrosion can take the form of acid leakage.

I would bet your meter is to small (amps) and your service entrance conductors are to small (amps) too. You also need the POCO to pull your meter and replace it. It is a very good thing you found this bad neutral connection now.

when to replace electrical panel box

old electrical panel boxes

Corrosion is not good between electrical contacts, where breaker contacts the bus bar. It causes increase in resistance, causing extra heat. Are you near salt water or smelly industrial plant? – A panel cabinet that has only minor corrosion should be evaluated to determine the cause of the corroded area, and then repaired, to keep the rust from advancing further. Rain leakage coming down a service mast, for example, can ruin a panel box and circuit breakers if not repaired promptly.

If you hear noises coming from your panel, your breaker box could be arching or vibrating caused by loose connections within the panel. This is a bad sign. If you see signs of corrosion in the electrical box. Corrosion happens over time when moisture is introduced within the panel.

Corrosion at interior components of an electrical panel creates several safety problems: 1) Circuit breakers are mechanical devices and, like any mechanical device, corrosion can cause it to freeze up and not trip when too much current is flowing in the circuit. Various things can cause damage to an electrical box, ranging from improper installation to corrosion. It could be a hairline crack on the top along a corner or a giant gaping hole created by rust deteriorating the box’s metal. Even if your electrical panel isn’t near a water source, remember that humidity can cause corrosion. When it comes to your electrical panel, always err on the side of being overly cautious. An experienced electrician can tell you whether your panel has safety issues.

Troubleshooting Tip – Regularly inspect your breaker box for signs of rust, corrosion, or deterioration, such as discolored or charred components. If you notice any damage, contact a licensed electrician immediately for repairs or replacement. The sheathing on one of the ground wires appears to be melted. A faulty appliance plugged into the outlet could have overheated the outlet if the circuit breakers (or fuses) weren't working properly. The corroded look on the wires could also have been caused by . When electrical wires are left alone too long in the elements, the metal in the wires can corrode. Electrical wires are usually made from copper and, as such, prone to oxidation. If connected to a battery, the subsequent corrosion can take the form of acid leakage.

electrical panel replacement problems

duplex electrical box extension

Today’s post offers a comprehensive guide to electrical enclosures, including the various types, the significance of enclosure ratings and construction materials, and how to choose the proper electrical cabinets or enclosures for different industrial applications.

electrical box too corroded|electrical panel box lifespan