cnc part programming g codes G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to .

In this video you'll learn how to wire junction boxes correctly. You'll also see our favorite tools to complete this task. We hope you enjoy this video. Thanks for watching and Have A Great.

0 · g code explained with examples

1 · g code commands cheat sheet

2 · g code cnc cheat sheet

3 · g code cheat sheet

4 · complete g code list

5 · cnc turning g code list

6 · cnc mill g code list

7 · cnc g code for beginners

“Switches and lighting controls now come with a green grounding screw or green pigtail wire, and are required to be connected to an equipment grounding wire or metal box that is grounded,” Williamson says.

g code explained with examples

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

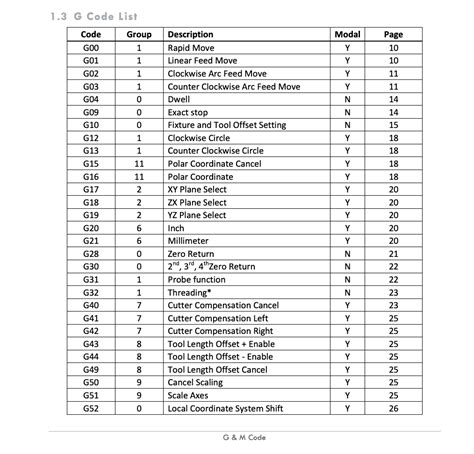

CNC G-codes & M Codes for milling and turning with explanations, . Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing.I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines

franklin electric control box 2hp

g code commands cheat sheet

CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool .

G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to . G01: Linear Interpolation. In CNC machining, the G01 code is essential for linear interpolation, where the tool moves from one point to another in a straight line at a specified feed rate. This process is fundamental for . G-codes differ in different CNC machines, while M-codes are the same in most CNC machines. G-codes command the machine’s motion and function for the product’s design, while M-codes are used to conduct the non .The most common codes used when programming NC machines tools are G-codes (preparatory functions), and M codes (miscellaneous functions). Other codes such as F, S, D, and T are used for machine functions such as feed, .

CNC | CNC part program, CNC programming | Introduction of part program | G code | M code #lecture 2In this video you will learn about part program which is u.

6. Part programming 1. Part programming consists of a sequence of instructions to be performed on the NC/CNC machine. 2. This are two types 1.Manual part programming. 2.Computer – aided part programming. CNC 3. In . CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. . CNC programming with G . Learn about the fundamentals of CNC programming and G-code including blocks, modals, address codes, canned cycles, and popular G&M codes. Fusion . The goal of every G-code program is to produce parts in the safest and most efficient way possible. To achieve this, you’ll typically find G-code blocks arranged in a particular order like this: .

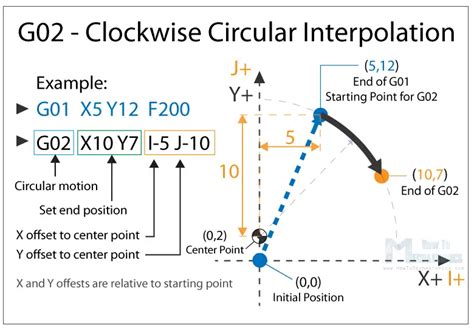

Understanding G codes is crucial for anyone involved in CNC programming or operation. The Role of G Codes in CNC Operations. G codes, short for “Geometry” codes, are the primary instructions that control the motion and cutting operations of CNC machines. They dictate various aspects of the machining process, including: Tool positioning and .G02 G03 Circular interpolation CNC mill example program. G02 G03 Example CNC Mill CNC Part Program G0 X30 Y-30 (P1) G1 Y22.67 (P2) G3 X24.07 Y26.18 R4 (P3) G2 X-18.27. If you are interested in CNC programming, one of the main steps in learning G codes is to learn circular interpolation with G02 and G03.. Circular interpolation is a fancy way of referring to programming a circular arc with G code. For this, you need to learn some easy math that allows you to specify any arc with two different methods: with I J K, or using R.

franklin electric irrigation pump control box plant city fl

CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while monitoring for any issues.

For a CNC machine tool, to make it move and complete the processing of a part, programming is an essential step. For a part of the processing quality, depends on the quality of its program. . CNCLATHING Introduction to G-Code and M-Code in CNC Programming | G-Codes & M-Codes for CNC Turning & Milling | CNCLATHING Thread Types, Terms .

Deliverable: Hand Written G-Code Part Program. Drilldown on the link to see our Free Tutorial on Hand Writing G-Code Programs. One of the first things you’ll learn in the tutorial is how to run a CNC Machine like a Manual Machine. If you already know manual machining on a mill or lathe, you can be doing exactly the same kinds of things quickly on a CNC too.

Beginner’s Guide to Using Conversational CNC to Program CNC Parts. Deliverable: A G-Code Part Program created using Conversational CNC. Conversational CNC is programming g-code by asking questions of the programmer in order to create operations that are similar to the operations a manual machinist might use. It does not require the use of a .Learn CNC Programming Basics, G & M Code Tutorials with Example Codes for Beginner to Advance Level CNC Machinist. G & M Code Programming Tutorial, Course, Examples. . CNC Machine Lock CNC machine lock is very handy function for testing a cnc program before actually making a part. In machine lock axis stay stationary on their positions, but. CNC programming is the backbone of modern manufacturing, and understanding the basics of G-Code and M-Code is essential for anyone working with CNC machines. These programming languages allow machinists to control everything from tool movement to spindle speed, ensuring precise, efficient, and consistent production of parts.Prepare a CNC part program to machine it on any turning center using the ISO standard G-codes. You may decide the program zero to be used for the component. Write the program using the initial tool position. The work material may be taken as mild steel. 15 32.5 53.5 Ø18 R1.5 Ø45 Ø23 Figure 8.1 : Part Drawing for the Programming Example 8.1 .

Study with Quizlet and memorize flashcards containing terms like 1.What is a part program? A part program is a(n):, 2.What does a coordinate code communicate to a CNC machine?, 3.What is computer-aided manufacturing? and more. Conversational Programming is a way to create simple g-code programs with CADCAM software. You simply answer questions in a simple Wizard format and it will generate the g-code for the operation. . Beginner’s .

G-code users can use conversational methods to quickly and easily program prismatic parts or routine operations such as part probing, tool measuring and part engraving. Mazatrol’s integrated system leads users . A G-Code in CNC Programming works like a controller and dictator. It controls the machine’s movement and dictates how and where it should move to formulate the end CNC machined product. . G Codes are used to make CNC Machines programmable and give CNC machines the flexible to make almost any part. CNC machines use G and M codes for CNC .N11- CNC part-program is ended. G & M Codes. Code Description; T: Tool no. used. M06: Tool change command. G90: Absolute programming: G54: Zero offset no.1: G00: Rapid traverse: S: Cutter speed: M03: Cutter rotation Clockwise: G43: . A complete cnc part-program which shows how G98 and G99 (canned cycle return level) work with G81 drilling .

A G-code to set measurement to either SI or US customary is usually found in the _____ block. - identification - control - start - setup. start. 1 / 19 . What is a series of numbered instructions that control the machine's movements and functions to create a part? - CNC system - CNC part program - CNC part drawing - G-code - Preparatory . Two types of G-codes exist in CNC precision machining: modal: remains effective until changed; non-modal: operates only within the block where used. Role of G Codes in CNC Machines. G-codes are essential in CNC programming, serving a crucial role in the automation of CNC (Computer Numerical Control) machining. CNC machines rely on these codes .Methods of CNC Programming with G and M Codes Manual Programming. Manual programming involves writing G and M codes by hand. The programmer creates the code based on the part geometry and machining requirements. Here's how it typically works: The programmer analyzes the part drawing and determines the necessary machining operations.N9- CNC part-program is ended. G & M Codes. Code Description; T: Tool no. used. M06: Tool change command. G90: Absolute programming: G54: Zero offset no.1: G00: Rapid traverse: S: Cutter speed: M03: Cutter rotation Clockwise: G43: . A complete cnc part-program which shows how G98 and G99 (canned cycle return level) work with G81 drilling .

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and . The first part of any program should be a .ISO CNC programming compared with G-code programming. Study of the file names and the structure of programs and subprograms. . In the first part of today’s lesson we completed the topic “Programming Method”. We saw the three programming possibilities: G-codes, SHOPMILL/TURN and ISO. .

CNC programming is essential for precise and complex manufacturing tasks. G-codes and M-codes are used to control CNC machines. It enables the transformation of raw materials into finished products with exceptional accuracy. CNC programming requires a strong understanding of the machine’s functions and tool positioning.

G-code is everywhere, from 3D printing to CNC. Easily learn the basics of CNC programming with this G-code tutorial in six simple steps.

g code cnc cheat sheet

Additionally, installing a transformer in a junction box allows high and low-voltage wires to come into contact with one another. The transformer is connected to 120V wiring from the service panel. However, it uses 24V wiring to take power to the doorbell button. You can insert a barrier to keep the wires separate.

cnc part programming g codes|g code cnc cheat sheet