sheet metal forming processes and die design SHEET METAL FORMING PROCESSES AND DIE DESIGN VUKOTA BOLJANOVIC, Ph.D. Doctor in Technical Science Industrial Press New York Library of Congress Cataloging-in-Publication Data Boljanovic, Vukota. Sheet metal forming processes and die design / Vukota Boljanovic. p. cm. Includes bibliographical references and index. Many times when you have a four speed that makes a raking sound when to shift gears most of the tome it is a broken brass ring. I have seen a lot of "Crash Boxes" this is where guys alter the four speed to get it to shift quicker. Sometimes guys will grind the teeth off of the brass blocking rings.

0 · sheet metal forming press dies

1 · sheet metal fabrication handbook pdf

2 · sheet metal die design pdf

3 · sheet metal design rules pdf

4 · sheet metal design handbook pdf

5 · sheet metal design calculations pdf

6 · sheet metal calculation formula pdf

7 · sheet metal bending process pdf

Hunter rainwater systems and zinc & aluminium fabrications. Merchant .

sheet metal forming press dies

fifth generation master roofer & sheet metal fabricator

sheet metal fabrication handbook pdf

Boljanovic, Vukota Sheet Metal Forming Processes And Die Design Industrial Press, Inc ( 2004) : Free Download, Borrow, and Streaming : Internet Archive.By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal forming processes and die design - still the most commonly used.The second edition of this best-selling text and reference provides an expanded and more comprehensive treatment of sheet metal forming processes, while placing forming processes and die design in the broader context of the .

Written by an engineer with decades of practical manufacturing experience, this new edition has been thoroughly revised and is a complete modern guide to sheet metal forming processes and die design - still the most commonly used methodology for the mass-production manufacture of aircraft, automobiles, and complex high-precision parts. Included are the "hows" and "whys" of .SHEET METAL FORMING PROCESSES AND DIE DESIGN VUKOTA BOLJANOVIC, Ph.D. Doctor in Technical Science Industrial Press New York Library of Congress Cataloging-in-Publication Data Boljanovic, Vukota. Sheet metal forming processes and die design / Vukota Boljanovic. p. cm. Includes bibliographical references and index.Written by an engineer with decades of practical manufacturing experience, this new edition has been thoroughly revised and is a complete modern guide to sheet metal forming processes and die design – still the most commonly used methodology for the mass-production manufacture of aircraft, automobiles, and complex high-precision parts. Included are the “hows” and “whys” of .

Drawing on his more than three decades of experience as an engineer in the field, Bojanovic offers a practical guide to what he says is still the most commonly used manufacturing methodology for mass producing complex, high-precision parts. He looks at such mechanisms as blanking, bending, deep drawing, material economy, the movement of metal durinSheet Metal Forming Processes and Die Design, 2e + 4090 Sheet Metal / HVAC Pro Calc Calculator (Set) by Vukota Boljanovic and Calculated Industries. Second Edition. 320 Pages, 8.00 x 10.00 x 1.00 in. Mixed media product; ISBN: 9780831136758; Availability: In Stock; Publication Date: August 2021; 4.95. BUY

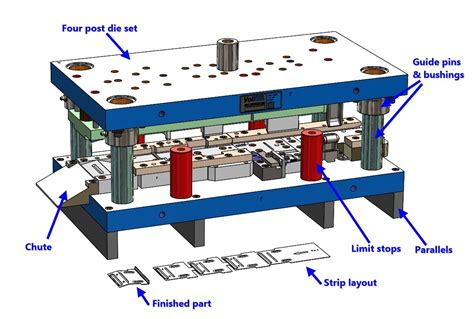

fibre optic junction box

It also covers die design for sheet metal forming processes, including formulas and considerations for parts, clearances, materials and complex die types. The goal is to offer practical engineering approaches rather than complex numerical techniques for sheet metal forming and die design. Read less. Read more.Sheet Metal Forming Processes and Die Design. . The design of bending dies depends on the complexity of the workpiece shape, its dimensions, the type of material, the tolerances, etc. 10.2 SIMPLE DIE DESIGNS. Some die sets are designed to perform a single bending operation, which may include V, L, U, or Z, bends and other profiles. Such dies .Sheet Metal Forming Processes and Die Design, 2nd Ed. Vukota Boljanovic 295 pages, Illustrated, 8 x 10 Published 2014 This long-awaited new edition of a best-selling text and reference provides an expanded and more comprehensive treatment of sheet metal forming processes, while placing forming processes and die design in the broader context of the .Sheet Metal Stamping Dies Die Design and Die-Making Practice. by Vukota Boljanovic. 224 Pages, 6.00 x 9.00 x 0.60 in. Paperback; ISBN: 9780831134631; Availability: Print On Demand; Publication Date: July 2012; .95. BUY EDUCATORS: REQUEST AN EBOOK REVIEW COPY. Description ; About the Author;

New York: Industrial Press, 2004. XIX, 219 p. ISBN10: 0831131829. By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal forming processes and die design - still the most commonly used methodology for the mass-production manufacture.Written by an engineer with decades of practical manufacturing experience, this new edition has been thoroughly revised and is a complete modern guide to sheet metal forming processes and die design - still the most commonly used methodology for the mass-production manufacture of aircraft, automobiles, and complex high-precision parts. The interaction of both computational sides is defined in terms of an appropriate data transfer routines (Fig. 1).For the process-only part, the forming simulation uses the geometry information from die-face design as rigid surface entities and the blank as an elastic–plastic deforming body, and the time-dependent displacement-driven binder and punch motion realize .

Description: Sheet Metal Forming Processes and Die Design. by Vukota Boljanovic. This long-awaited new edition of a best-selling text and reference provides an expanded and more comprehensive treatment of sheet metal forming processes, while placing forming processes and die design in the broader context of the techniques of press-working sheet metal.

Summary: Annotation Written by an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal forming processes and die design-still the most commonly used methodology for the mass-production manufacture of aircraft, automobiles, and complex high-precision parts. It illustrates several different approaches to this intricate .

By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal forming processes and die design still the most commonly used methodology for the mass-production manufacture of aircraft, automobiles, and .

By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal forming processes and die design – still the most commonly used methodology for the mass-production manufacture of aircraft, automobiles, and complex high-precision parts. It illustrates several different approaches to this .

SHEET METAL FORMING PROCESSES AND DIE DESIGN Second Edition VUKOTA BOLJANOVIC, Ph.D. Industrial Press SMSD_00.indd iii 15/01/14 9:28 AM. A full catalog record for this book is available from the Library of Congress. ISBN 978-0-8311-3492-1 Industrial Press, Inc. 32 Haviland Street, Unit 2CThe Book/EBook combo is a modern guide to sheet metal forming & die design. Illustrates the how's & whys of product analysis. Order now at threadcheck.com. . Sheet Metal Forming Processes and Die Design; Sheet Metal Forming Processes and Die Design. SKU. 9780831131821. .95. Qty. Add to Cart. Add to Quote.By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal forming processes and die design still the most commonly used methodology for the mass-production manufacture of aircraft, automobiles, and complex high-precision parts. It illustrates several different approaches to this .This chapter presents two case studies; one demonstrating the use of finite-element analysis (FEA) in the design of a progressive die forming operation, the other explaining how software simulations helped engineers reduce thinning and eliminate cracking and deformation observed in clutch hubs formed using a three-step transfer die process.

With regard to sheet metal forming, especially to the auto panel forming process, high forming quality demands that any kind of rupture or wrinkling should be avoided. In addition, the defect of an unstretched area in the part must also be eliminated. If the metal is not strained sufficiently, it will not hold its shape for shallow curvature.

He is the author of five books, including from Industrial Press, Sheet Metal Forming Processes and Die Design (2004) Die Design Fundamentals, Third Edition (2005), Applied Mathematical and Physical Formulas (2015 ) and Metal Shaping Processes (2009). He has contributed updated practical material on sheet metal design, including punches, dies .SHEET METAL FORMING PROCESSES AND DIE DESIGN Second Edition VUKOTA BOLJANOVIC, Ph.D. Industrial Press SMSD_00.indd iii 15/01/14 9:28 AM. A full catalog record for this book is available from the Library of Congress. ISBN 978-0-8311-3492-1 Industrial Press, Inc. 32 Haviland Street, Unit 2C Press: A mechanical or hydraulic press provides the necessary force to shape the metal. Metal sheet or blank: The raw material, typically in the form of coils or pre-cut blanks, is fed into the press. Stages of stamping: a. Blanking: Cutting the initial shape from the metal sheet. b. Drawing: Forming the metal into a three-dimensional shape.

The process of sheet metal forming is one of the very important processes in manufacture of products mainly in the automotive field. In sheet metal forming, it is added a certain size at the die .

With a plethora of options, colors, and sizes, you'll find the ideal geometric fabric to suit your unique taste. Explore our selection today and discover how our .

sheet metal forming processes and die design|sheet metal bending process pdf