sheet metal forming applications In this blog, we dive into seven key sheet metal forming processes that shape modern manufacturing: Laser Cutting, Water Jet Cutting, Stamping, Welding, Roll Forming, Spinning, and Rolling. . Applications of Roll Forming. Roll forming is widely used across various industries, including construction, automotive, home appliances, and storage . Made with heavy-duty TRU16 gauge stainless steel for long-lasting durability with great resistance to corrosion, dents, and damage. Undermount sink installation creates a clean transition from sink to countertop and simplifies cleanup by letting you wipe water and crumbs right into the sink.

0 · sheet metal layout drawings

1 · sheet metal forming types

2 · sheet metal forming process pdf

3 · sheet metal forming press dies

4 · sheet metal forming pdf

5 · forming sheet metal by hand

6 · forming process in sheet metal

7 · bulk deformation vs sheet metal forming

Cover for Underground Enclosure, R Series, 10 x 15 x 1-3/4 Inch, Legend: ELECTRIC, Skid Resistant, Rated Light Duty/Pedestrian Traffic, Composite With UV Inhibitor

In this blog, we dive into seven key sheet metal forming processes that shape modern manufacturing: Laser Cutting, Water Jet Cutting, Stamping, Welding, Roll Forming, Spinning, and Rolling.Sheet Metal Forming: Processes and Applications covers all major sheet forming operations including blanking, bending, flanging, deep drawing, stamping, spinning, clinching, and crimping. It describes the forces, stresses, and . Metal forming : fundamentals and applications by Altan, Taylan. Publication date 1983 Topics Metal-work Publisher Metals Park, OH : American Society for Metals Collection internetarchivebooks; inlibrary; printdisabled . Sheet metal forming is the transformation of a metal sheet into a fully realized 3D product. Check out our guide to the sheet metal forming process. . Aluminum: This metal is used in applications that need light and corrosion .

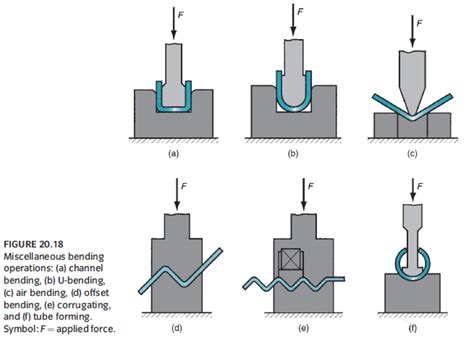

In this blog, we dive into seven key sheet metal forming processes that shape modern manufacturing: Laser Cutting, Water Jet Cutting, Stamping, Welding, Roll Forming, Spinning, and Rolling. . Applications of Roll Forming. Roll forming is widely used across various industries, including construction, automotive, home appliances, and storage . Introduction In a typical sheet metal forming application, the sheet surface is lubricated. The lubricant can potentially change the contact condition between the tool and the sheet surface from boundary to the mixed lubrication regime. The lubrication condition depends on the lubricant amount, loading conditions and other process parameters. Due to wide range of applications, the process of forming the sheet metal into various shapes leads to classification of the forming processes based on specific operation. This classification involves bending, blanking, stretch forming and deep drawing. . Coming to the sheet metal forming processes itself, drawing and bending are the two most . In order to utilize different types of materials for manufacturing sheet metal parts, formability is the vital issue in sheet metal forming. [30,33, 34, [38][39][40][41][42] In this context of .

This paper is devoted to the determination of the coefficient of friction (COF) in the drawbead region in metal forming processes. As the test material, AW-5251 aluminium alloys sheets fabricated .Sheet metal surfaces are generally textured to improve tribological performance in deep drawing applications. Variations in coefficient of frictionFriction in forming processes is one of the major causes of defective products. The major reasons for an unstable. The fundamental principle behind sheet metal forming lies in the application of controlled forces, engaging the material’s inherent plasticity. These forces, deftly applied through meticulous shaping, bending, and stretching, coax the metal into assuming intricate contours and geometric marvels that would otherwise remain elusive.

The aim of sheet metal forming is to produce parts made of thin sheet metal for utilization in a diverse range of applications. Sheet metal forming is an extremely flexible process that exploits the strength and ductility of sheet metal to create long-lasting parts, which are more cost-effective compared to similar manufacturing processes like .His research interests include computer aided sheet metal die design, AI applications to sheet metal forming, CAD/CAM, AutoCAD application and customization, and CAPP. He has completed many research projects in the area of design and manufacturing sanctioned by various funding agencies. He is a member of the Egyptian Syndicate of Professional .Sheet metal forming

In this work, formabilities of aluminum sheet alloy grade AA5052-H32 were investigated under consideration of the anisotropic behavior of material. Experimental tensile tests and modified Marciniak in-plane stretch-forming tests of sheet samples with varying shapes were performed for different sample orientations. The critical fracture strains at various states of . In this manuscript, we present a comprehensive overview of true digital twin applications within the manufacturing industry, specifically delving into advancements in sheet metal forming. A true digital twin is a virtual representation of a physical process or production system, enabling bidirectional data exchange between the physical and digital domains and .This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equipment, tooling, and process modeling. Individual chapters cover all major sheet forming processes such as blanking, bending, deep drawing, and more. Process modeling using finite element analysis is described in one chapter and discussed in all appropriate . Over the last years, the numerical simulation of integrated processes has become the major challenge in virtual try-out of sheet metal components, including trimming operations that may occur between forming steps. Detailed simulation of trimming processes is a challenging task, particularly when integrated with other forming operations such as deep drawing or .

sheet metal layout drawings

The Ultimate Guide to Sheet Metal Forming Machines: Types and Applications is an invaluable resource for engineers, manufacturers, and technicians involved in sheet metal fabrication. By providing detailed information on the different machine types, selection criteria, and practical applications, the guide empowers readers to make informed .Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight . Examples-sheet metal formed . Female die Male die (punch/post) Metal sheet Blank holder (ring) on cushion CompressibleThe lubricity, hardness and abrasion resistance of these PVD coatings reduces friction between the sheet metal and tool, resulting in 8 to 40 times longer tool life, more press up-time and improved part quality. . Our best coating for tough metal forming applications is CrN. It has excellent lubricity, is very tough, and has good wear . Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. . It offers various grades to use in forming applications. Some common examples include; hot rolled steel, cold rolled steel, and tool steel. Among these .

There’s no denying that sheet metal plays a pivotal role in projects across numerous industries. Sheet metal is commonly fashioned from steel or aluminum and typically takes a thin and flat form. Despite this, sheet metal alterations are commonplace — and essential — depending on the application in question. This is where the forming of sheet metal parts .

Over the last 15 years, the application of innovative steel concepts in the automotive industry has increased steadily. Numerical simulation technology of hot forming of high-strength steel allows engineers to modify the formability of hot forming steel metals and to optimize die design schemes.

3 Forming Strategies to Overcome the Forming Limit of Aluminum Alloys. Sheet metal forming processes for thin-walled aluminum alloys require different thermomechanical forming concepts depending on the chemical composition, strengthening mechanisms, application areas, and geometrical requirements. Forming is the most widely used sheet metal operation used for manufacturing various sheet metal components across the industry.. Sheet Metal Forming . Image courtesy: Wiki Based upon the manufactured components and the manufacturing process, various kinds of forming are developed.. Different types of sheet metal forming processes and their .

The applications of such lubrication regime are sheet metal forming (Shisode et al. 2020), mechanical seals (Nyemeck et al. 2012), constant-velocity joints (Spikes and Olver 2003) and tribo . From choosing suitable material to precision sheet metal fabrication, fabricating aerospace sheet metal parts can be challenging. The best part, today’s guide explores all fundamental facts about aerospace sheet metal fabrication. Whether you want to choose a suitable material, fabrication technique or understand practical applications – all information .

used sheet metal slitter

sheet metal forming types

UNDERMOUNT INSTALLATION creates a seamless transition from sink to .

sheet metal forming applications|sheet metal layout drawings