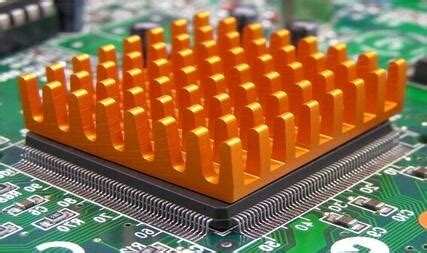

cnc machining heat sink CNC Machining Heat Sinks combine the precision of CNC machining with the heat-dissipating functionality of heat sinks. This fusion allows for the creation of heat sinks with intricate geometries, optimized surface areas, and improved . 3/16” & thicker is plate SHEET GAUGE CHARTS ALUMINUM GAUGE* THICKNESS 22 0.025” 20 0.032” 18 0.040” 16 0.050” 14 0.063” 12 0.080” 11 0.090 10 0.100” 0.125” 0.160” 0.190” Note: There is no official gauge standard for aluminum. .250” & thicker is plate *Brown & Sharpe’s Gauge Standard B & S or American Gauge A.W.G. BRASS

0 · heat sink machining companies

1 · heat sink machining

2 · heat sink cutting process

3 · copper heat sink reviews

4 · copper heat sink cnc

5 · copper heat sink

6 · cnc heat sink machine

7 · be cu heat sink

Metal fabrication is the creation of products or structures through cutting, bending, and assembling metal materials. It is typically a process that consists of putting things together using raw materials, like metal, expanded metal, welding wires and rods, cast metal, and more.

CNC machining allows the creation of highly accurate and precise heat sink designs with tight tolerances and complex geometries. This allows the production of heat sink with optimum thermal performance, tailored to the . Had a customer job come in for a heat sink! Using a 4" side cutter (e.g. slotting) cutter to do most of the work, then cleaning up with a 1/8" end mill! Plus the usual shear hog, superfly, etc.CNC Machining Heat Sinks combine the precision of CNC machining with the heat-dissipating functionality of heat sinks. This fusion allows for the creation of heat sinks with intricate geometries, optimized surface areas, and improved . Discover how heatsync and heat sinks keep your devices cool, protect critical components, and explore the latest solutions for efficient thermal management.

This guide will cover all aspects of heat sink design, including principles, materials, and selection criteria. Different types of designs and the significance of thermal resistance in .

CNC machining. CNC machining is the finest way to create heat sinks with complex designs. The designers get a great deal of flexibility with this approach. An entire metal block can be used to create the sink where the .CNC machining provides a variety of manufacturing processes by incorporating 3-axis and 5-axis CNC machines to make high-precision heat sinks with simple and complex designs. Milling: .4 Richconn’s Heat Sink Design and Machining Capabilities. How Heat Sinks Work. To understand how heat sinks work, we need to first understand the basic concept of heat transfer and thermal resistance. Heat transfer is the process .

With highly versatile machining capabilities, Radian Thermal Products provides high precision heatsinks with complex features, contours, cut-outs and through-holes. Combined with a full range of finishing we are your reliable source for .

CNC machining is well-suited for designing heat sinks with the most complex specifications. CNC-machined heat sinks are ideal for devices requiring high thermal conductivity or complex design options. CNC machining has benefits over extrusion and die casting for heat sink manufacture. CNC machining is suitable for bespoke heat sink designs because it accurately removes material from a solid block. High-precision accuracy.Precision is a major benefit of CNC machining. CNC machines can precisely size heat sinks for your application. CNC-machined heat sinks are ideal for devices requiring high thermal conductivity or complex design options. However, this process can be pretty costly. . AT-Machining. Heat sink design is fundamental to the . Worthy Hardware is a Precision CNC Machining Parts and Sheet Metal Fabrication vendor for 100+ material with free samples in global shipping. Get it now! About. About Us; . Where the construction of complex heat sinks .

Skived Heat Sink Benefits/Features. Skived heatsink can be an alternative to extruded heat sink when looking for a fin density which can NOT be achieved by extrusion technology.; Skived heatsink fabrication does not need expensive tooling which provides greater design flexibility.Instead, each fin is cut separately using the same tool which allows for lower tooling . Understanding CNC Machining and Heat Sink Fundamentals. CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, offering unparalleled precision, repeatability, and efficiency. This technology employs computerized controls and machine tools to remove layers of material from a stock piece—known as the . Heat sinks produced with skiving have a very high aspect ratio, which reduces the weight of heat sinks. The tooling cost is minimal as only a sharp blade is used. Another advantage is that the lead time of the skiving process is very short as only slicing and bending operation is required to produce a final product. The Role of Advanced CNC Machining in Heat Sink Production. Advanced CNC machining techniques play a critical role in the production of high-quality aluminum heat sinks. CNC machining is a computer-aided manufacturing process in which a computer-controlled machine tool is used to remove material from a workpiece, creating a desired shape with .

Depending on their shapes and materials, heat sinks can be made by many manufacturing methods. The most common and cost effective methods include extrusion, forging, casting and stamping. . Other higher-cost methods include CNC machining, skiving and swaging. Although they are expensive, they can produce heat sinks with features that cannot .

heat sink machining companies

heat sink machining

Heat Sinks Manufacturer, Pioneer Thermal Heat Sink is a leading custom heat sink supplier, cooling heat sinks solution in China.Pioneer focuses on the design and production of extrusion heat sink, skived fin heat sink, forged heat sink, air cooling radiators and cooling heat sinks, thermal solution products, CNC machining, aluminum extrusion and so on.

With every passing day, new machines are being developed which require high-performance thermal power management systems. To meet the demands of complex design heat sinks, CNC machining provides advanced manufacturing methods listed below. 5-axis machining: With 5-axis machining, you can conveniently control the workpiece 5 simultaneous directions.

In the world of thermal management, choosing the right heat sink material can make all the difference in device performance and longevity. At Kingka, we're dedicated to providing custom heat sink solutions tailored to the high-power cooling needs of industries like renewable energy, electronics, and automotive.With our extensive experience in heat .

Heat sinks are crucial elements in electronic devices’ thermal management systems, and they dissipate the excess heat produced while these devices are working. . I’m Liang Ting, the author of this blog. Specializing in CNC machining services for twenty years now, I am more than capable of meeting your needs when it comes to machining .

Heat Sink CNC Precision Machining Aluminium Extrusion Profile Metal Stamping. Contact Us Shishan Town,Nanhai District, Foshan, Guangdong, China [email protected] +86-18502086016. Follow Us. Newsletter. Please subscribe our newslatter and get the latest news and products. Keep close contact with our outstanding team In addition, CNC machining of aluminum heat sinks should pay attention to the following issues: (1) If the aluminum heat sink is too high, especially when processing some high-power heat sinks, you should use milling cutters of different lengths to roughen it in layers. After roughing with a large milling tool, it should be finished with a .High-quality custom heat sinks manufacturing for reliable, efficient cooling solutions. Perfect for various industrial needs. Get a quote! QMS 9001:2015 Certified. . Heat sinks can be manufactured through a variety of processes, including die casting and CNC machining. In manufacturing heat sinks for our customers, .Heat Sink Solutions By Casting &Cnc Machining. IATF 16949 CERTIFIED CAST MANUFACTURING AND CNC MACHINING FOR HEATSINK PARTS . Strictly speaking, heat is not a kind of energy, but just a way of transferring energy. .

Extruding heat sinks. Rows of identical parts with a uniform cross-section are ideal for extrusion. Extruding heat sink fins creates nearly complete shapes requiring minimal complex CNC machining. We often order ready . The final heat sink can be machined using normal fabrication techniques, such as CNC machining. Skived heat sinks require minimal tooling cost, which makes it a cost effective solution. Skived heat sinks can also be customized with embedded heat pipes to further .

2011 (5073) October (6) September (900) August (930) July (930) Auto heat sink; Auto heater exchange; Auto heater exchanger; Auto heater exchanger; Automatic Radiator Heat Sink Cutting MachineAfter a series of tests of silicone grease and liquid metal heat conduction agents, the results obtained led the author to look at the situation that the temperature difference of most high-end silicone grease in the market was no more than 5 degrees Celsius at the processor core frequency (120W power consumption).And liquid gold can open the gap of about 10 degrees .DEJIN is a China Machining Parts Manufacturer, provides precision soldering/brazing/bonding heat sink, aluminum extrusion heatsink and cold plate. We have R&D team and many mould, any heat sink requirements, welcome to contact us.

Author:Peter Krish Report date:May 20, 2023, 8:58:40 PM Summary. This example models the cooling characteristics of the n19 aluminum heat sink from Alpha Company Ltd The model studies the temperature distribution in the sink and in the flow. Some of the benefits of machined heat sinks include: CNC machining provides a good degree of design flexibility; Machining a heat sink also yields a product with almost unrivaled thermal conductivity; Machined components make sense for low-volume, potentially luxury-tier goods emphasising performance, longevity and durability over cost .CNC Machining. Additives. As one leading Electronic module and Heat sink manufacturer in India, Claire has been in the Thermal industry for more than 4 years. We provide thermal solutions with simulation, fans, Power module best in the industries. We manufacture and provide all types of heat sinks with Aluminum or Copper material, refers to .

Richconn, a precision machining company, is known for its superior heat sink design and machining capabilities. With advanced technical equipment and a professional team, the company is committed to providing customers with efficient and innovative heat dissipation solutions. . China 4-Axis & 5-Axis CNC Machining. CNC Milling Services . You might try chemically etching the aluminum surface to add pitting after machining to increase surface area. The rougher the surface, the more surface area. Some of the more efficient aluminum heat sinks have a rippled surface to increase surface area. Don Clement Running Springs, California

Heat Dissipaters Heat Plates. Metal Core-Fiber Fill Modified Extrusion Custom Bonded Fin Heat Sinks. Process. Drilling Routing. Machining. Equipment. CNC Controlled Multi-Spindle High Speed. Materials. Aluminum Copper/Moly/Copper Copper/Invar/Copper Steel. Brass Core Filling (Sumitomo X 28057-2HT) Material Form. Plate Extrusion Sheet. Length .

heat sink cutting process

copper heat sink reviews

A typical landline phone wiring diagram may also include additional components, such as a telephone distribution module (TDM) or a junction box. These components help to distribute the telephone signals to different rooms or devices within a building.A solar panel junction box is a critical component of any solar energy system, allowing the safe connection between the photovoltaic (PV) panels and the rest of the electrical system.

cnc machining heat sink|heat sink cutting process